Maintenance North Sea Canal by SPIE

Rijkswaterstaat (part of the Dutch Ministry of Infrastructure and Water Management) is investigating what maintenance must be done to keep the current lock in operation until the new lock is delivered. They do this together with TNO (The Netherlands Organisation for applied scientific research) and maintenance company SPIE.Rijkswaterstaat has outsourced the maintenance of the infrastructure in the North Sea Canal to SPIE. SPIE is responsible for an area with 13 movable objects: bridges, locks and pumping stations, but also for dams and the (green) facilities around the waterways.

Our measurement challenge

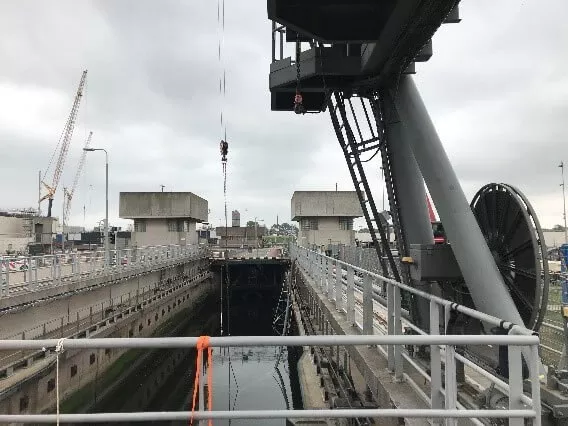

The lock has two large lock gates. When they are opened for ships, the gates slide over rails into the quay. The rails lie on a concrete foundation under water. But water makes concrete brittle over time. If the damage becomes too great, the rails start to jump when the gates are moved in and out and can break in the worst case. In order to develop a suitable maintenance plan for the lock, SPIE needed to know exactly how the rails behave when the gates are passed over.

The multi-technical services of SPIE

SPIE offers multi-technical services for buildings, facilities and infrastructures. The range of services include system solutions in technical facility management, energy efficiency solutions, technical services in energy transmission and distribution, services for industrial customers and services in the fields of electrical and security technology, heating, air conditioning and ventilation technology as well as information, communication, network and media technology.

A plug & play measuring system for the airlock

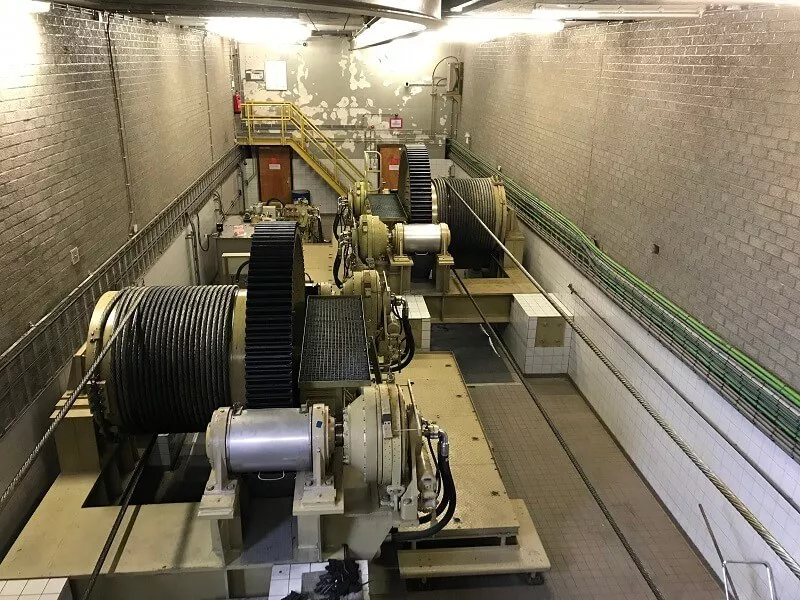

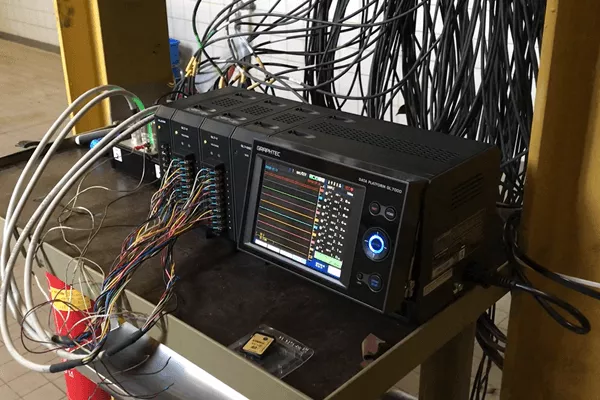

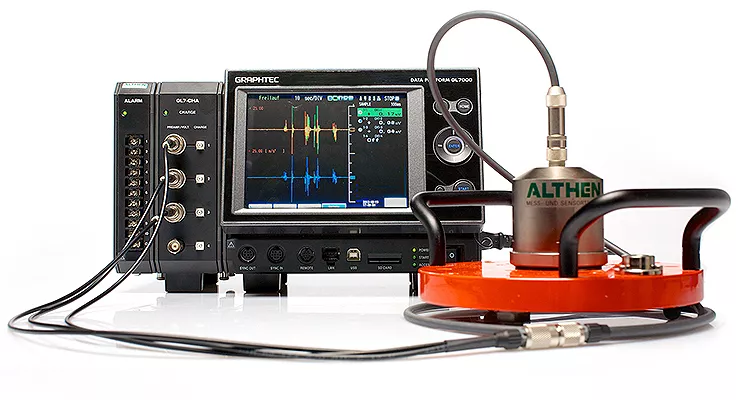

Althen was asked to help with the measurement of the rail suspension and delivered a complete measurement system only two weeks after the first contact. Divers placed 20 linear position sensors on the rails (10 sensors on each rail). The S114 linear position sensors are robust, very precise and particularly suitable for underwater use. When opening and closing the sluice gates, the system measures the strength of the rail movement. The combined measurement results are recorded in a GL 7000 data logger. Thanks to the plug-and-play concept, the system was ready for use just half an hour after installation.

Use of the measuring system

The 20 position sensors were connected to the GL7000 data logger with 100 m long cables via junction boxes specially developed by Althen. The measurement data can be monitored live on the data logger's display. The measurement results can be stored in real time, exported or read out remotely.

After two weeks, the collected measurement data was sent to TNO (Netherlands Organization for Applied Natural Science Research). They analysed the data and prepared a report for Rijkswaterstaat. Based on this report, SPIE prepared a detailed maintenance plan for the Noordersluis.

You can see a model of the planned new lock in the video here. More information about the project can be found on the Rijkswaterstaat website.

Accept the marketing cookies to view this video.

Click here to change your consent.

Products

GRAPHTEC Data Platform GL7000 System

- Digital interfaces USB 2.0 and Ethernet

- 7 types of Input Modules

- 4 types of Function Modules

S114 (Submersible) Linear Inductive Position Sensor

- Measuring range: 0 to 800 mm

- Sealed to IP68 - 10bar, 100msw, 145psi

- Outstanding overall performance