WESA-Control GmbH from Stade is an innovative company with a focus on industrial automation in the field of mechanical and plant engineering. The focus is on sensors for industrial valves. For this purpose, WESA-Control GmbH develops new measuring methods with which the valves can already be tested when they are installed, i.e. in the so-called operating state.

Why valve diagnostics?

During the operating process, there are inevitably changes in the tightness and closing force of the valves. Under certain circumstances, these can endanger the ongoing operation. Therefore, the continuous performance of a valve diagnosis, e.g. in chemical plants and power stations, is a must for every operator. By measuring and recording the changes, failures can be avoided in time and necessary maintenance work can be better planned. Current measurement results can be used for economic, safety-related and functional decisions. This test procedure is unique in the world so far.

Who benefits from the recorded data?

The plant operator benefits from the recordings and evaluation of the measurement data, as he has an overview of the changes to his valve due to process use at all times. For maintenance and servicing departments, the measurements are just as important. For example, when installing butterfly valves, the installation torque should be known. However, errors often occur here, but these can be avoided with a measurement of the torsional measuring coupling (TMK) and a data logger. Diagnostics is also suitable for test benches on which actuators and valves are tested. Valve manufacturers or repair companies can also use the measurement results as proof of quality for the respective valve or actuator. The different characteristics of the valves can be stored in a database. This is of great benefit for further service and inspection work.

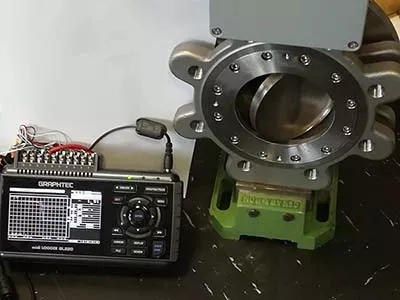

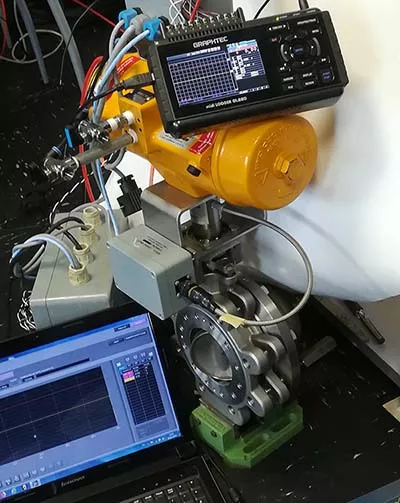

What does the compact Graphtec GL 220/240 data logger do?

For the valve diagnostics, various measuring methods and models were tested by WESA-Control. The choice of the right data logger fell on the GRAPHTEC midi Logger GL220 (successor model: GL240) from Althen. The extreme versatility with regard to the recording of measured values and range settings suited the development work at WESA-Control very well. The recording possibilities, evaluation and individual measurement results very quickly confirmed the success of the designs. The space-saving device can also be operated with a rechargeable lithium-ion battery and thus offers a wide range of possibilities for mobile use. Due to the wide application of the measuring ranges in the data logger, lifting valves and control valves can also be measured and evaluated excellently. Thanks to the positive experience gained, the data logger from Althen has since been used by WESA-Control for valve diagnostics. The current successor model of the GRAPHTEC midi Logger GL220 is the GRAPHTEC GL240.

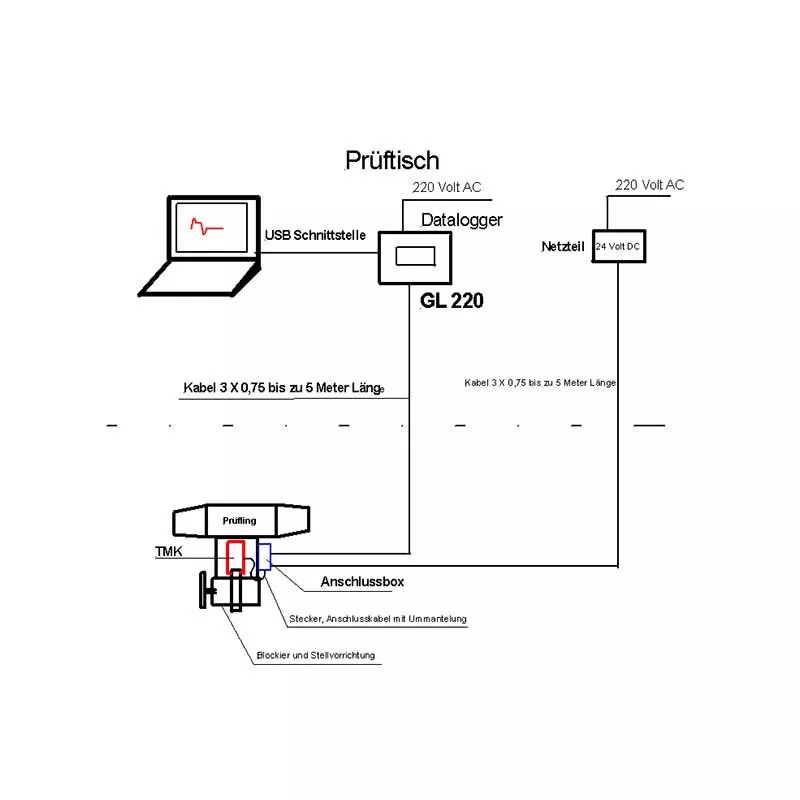

How does the procedure work?

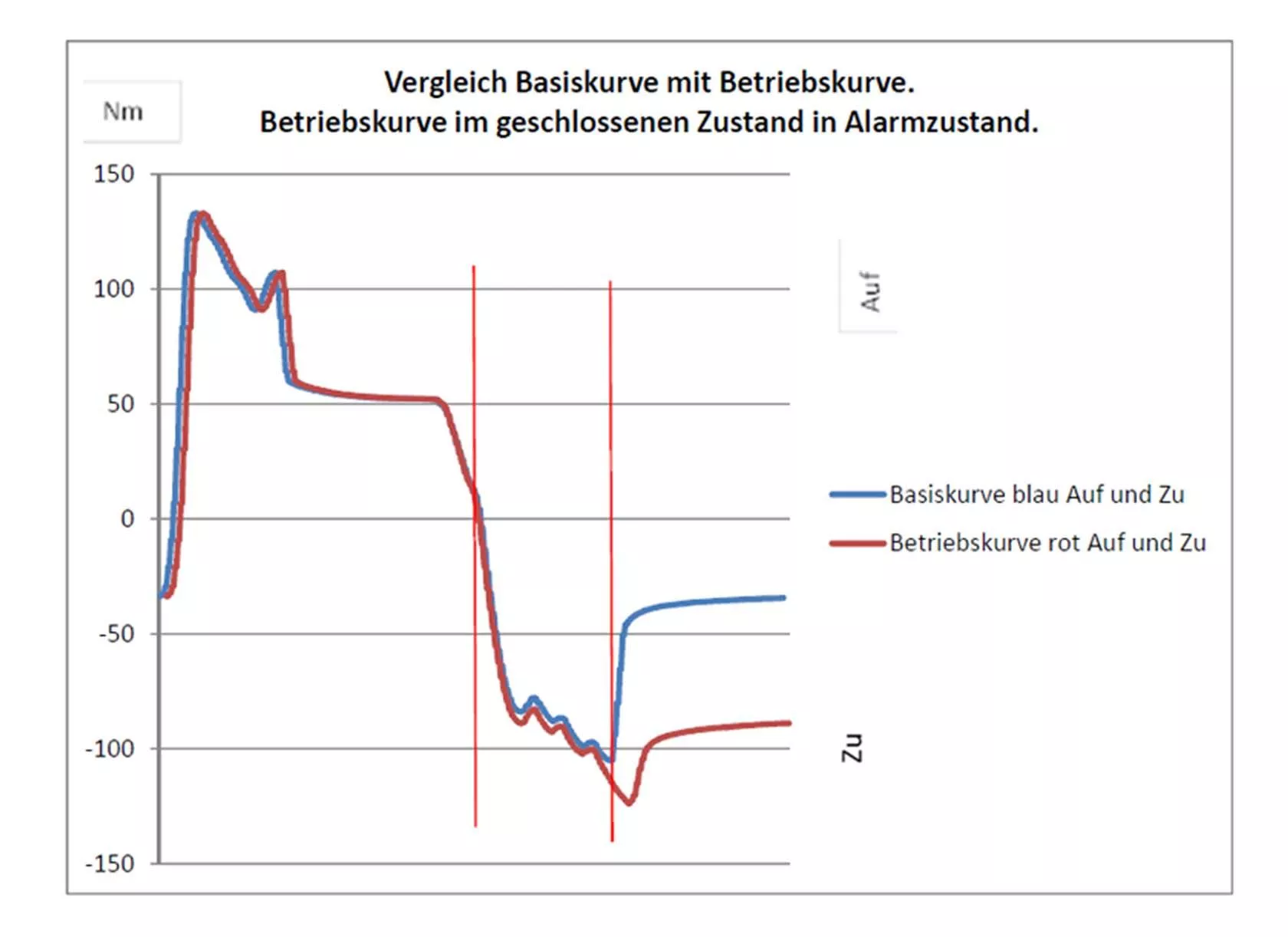

The measurement result of the torsion measurement coupling (TMK) is read in mV from the data logger, recorded and made available for evaluation. At the same time, the drive pressure and the travel from 0° to 90° are also recorded. Torque, pressure and travel thus show in an ideal way how the frictional forces in the fitting behave accordingly. The frictional forces and the existing torque are important to ensure the tightness and functionality of a valve. Now a base curve is recorded and stored in the new state. With each movement in the operating state, the base curve and the freshly generated operating curve are now compared. Even at standstill and at every angle of rotation, a usable measurement result is obtained - the great advantage of this measuring method over conventional methods. The graph on the left shows that a change has occurred in the closing area. Here it can be clearly seen that a deposit of 0.2 mm on the sealing rings causes a large change in the display (from 45 Nm to 94 Nm). WESA-Control's experience with this measuring method enables a cost-reducing, economical valve diagnosis.

GRAPHTEC GL840-M Multichannel Data Logger

- Measuring Ranges: Voltage, Temperature, Humidity, GL100 Sensors

- Measuring Channels: up to 200

- Resolution: 16 bit

GL100 | GL840 Sensors and Input Modules

- Different sensors and input modules for the GL100 and GL840

GRAPHTEC GL840-WV Multichannel Data Logger

- Measuring Ranges: Voltage, Temperature, Humidity, GL100 Sensors

- Measuring Channels: up to 200

- Resolution: 16 bit