Pressure measurement in tanks

Latest technology and inductive measuring techniques

Pressure sensors, also called pressure transmitters, are based on the latest piezoresistive foil strain gauges and inductive measurement technology. Pressure sensors can be used for a wide variety of media and applications, such as monitoring water pressure or measuring pitot pressure. In aerospace engineering, our piezoresistive pressure sensors help distribute pressure across the wing’s surface. They are also used in braking systems for cars and in gas turbine tests. Pressure sensors are available with analog or digital outputs for measurement ranges between 0.5 mbar and 12,000 bar.

We offer standard pressure sensors but can also help you with a customized desin or a complete measurement solution.

Pressure sensors are devices that detect and measure the pressure of a gas or liquid. They convert the physical pressure into an electrical signal, enabling accurate pressure monitoring and control in various applications. Pressure sensors utilize different technologies such as strain gauges, capacitive sensors, piezoelectric, or resonant frequency principles. They play a vital role in ensuring safety, optimizing processes, and enabling precise measurements. Pressure sensors work based on the principle of detecting and converting physical pressure into an electrical signal. These sensors utilize different technologies to achieve this. One common technology is the strain gauge principle. Strain gauge pressure sensors consist of a thin conductive film bonded to a flexible diaphragm. When pressure is applied, the diaphragm deflects, causing strain in the conductive film. This strain alters the electrical resistance of the strain gauge, which is then measured and converted into an electrical signal representing the applied pressure. Althen Sensors offers both digital and analog output options, allowing you to choose the best format for your application and data processing needs.

We offer a wide selection of pressure sensors for use with liquids and gases in all industrial applications. You can also benefit from our extensive services surrounding sensor and measurement technology: From pressure sensors and transmitters to barometers and differential pressure sensors, standard or miniature configurations, with and without ATEX certification. Most pressure sensors are suited for a wide variety of purposes. These sensors are used in industries like automotive, healthcare, manufacturing, and environmental monitoring. They play a vital role in ensuring safety, optimizing processes, and enabling precise measurements.

Althen Sensors offers an extensive product portfolio, encompassing various types of pressure sensors such as piezoresistive, capacitive, and ceramic sensors. This wide range ensures that they can cater to an array of applications with different requirements. These sensors are renowned for their high accuracy and precision. This is essential for applications where even the slightest deviation in pressure measurement can lead to costly errors or safety risks. Althen Sensors offers both digital and analog output options, allowing you to choose the best format for your application and data processing needs.

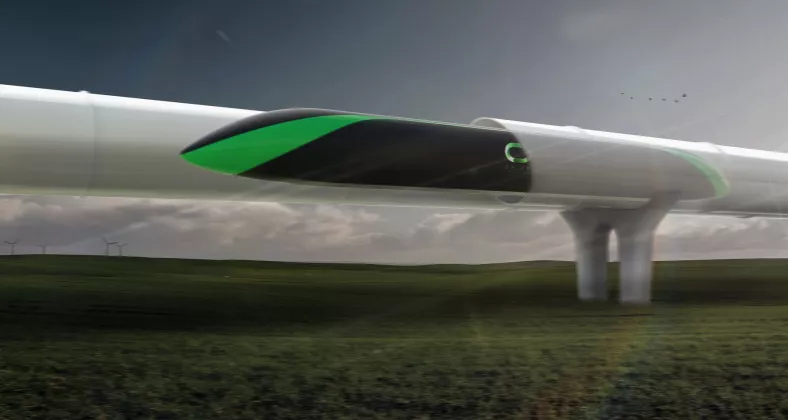

In the automotive industry our pressure sensors for instance contribute to automotive systems, such as engine management, tire pressure monitoring, and fuel injection systems, ensuring safety and efficiency. Where in aerospace and defense the pressure transmitters play a critical role for altitude monitoring, flight control systems, and hydraulic systems. There are many other applications and industries for pressure sensors like for instance industrial information, offshore and the maritime sector. Discover some of our pressure sensor projects.

Althen also offers a broad selection of custom solutions for pressure measurements in your specific applications. By offering customization options, Althen Sensors ensures that their pressure sensors can be tailored to the unique needs of each client and application. This level of flexibility allows our clients to achieve optimal performance and efficiency in their systems while maintaining the highest levels of accuracy and reliability. It also demonstrates our commitment to providing solutions that address the specific challenges and demands of our customers. In order to identify the right sensor for your application, we start by checking all the requirements. This includes the following information: