A small sensor with a big role

At first glance, a strain gauge doesn’t look like much. It’s a tiny zig-zag foil pattern, usually glued onto a piece of metal surface. Yet this small sensor plays a big role in measurement technology. From weighing a fully loaded truck, to monitoring stress in a bridge, to ensuring safe loads in cranes — strain gauges quietly do the heavy lifting.

Why small changes are hard to measure

The changes a strain gauge detects are microscopic. A small stretch or compression changes its electrical resistance by only a fraction of an ohm. That’s far too small to measure directly with standard instruments. Without the right setup, the signal would be lost in the noise.

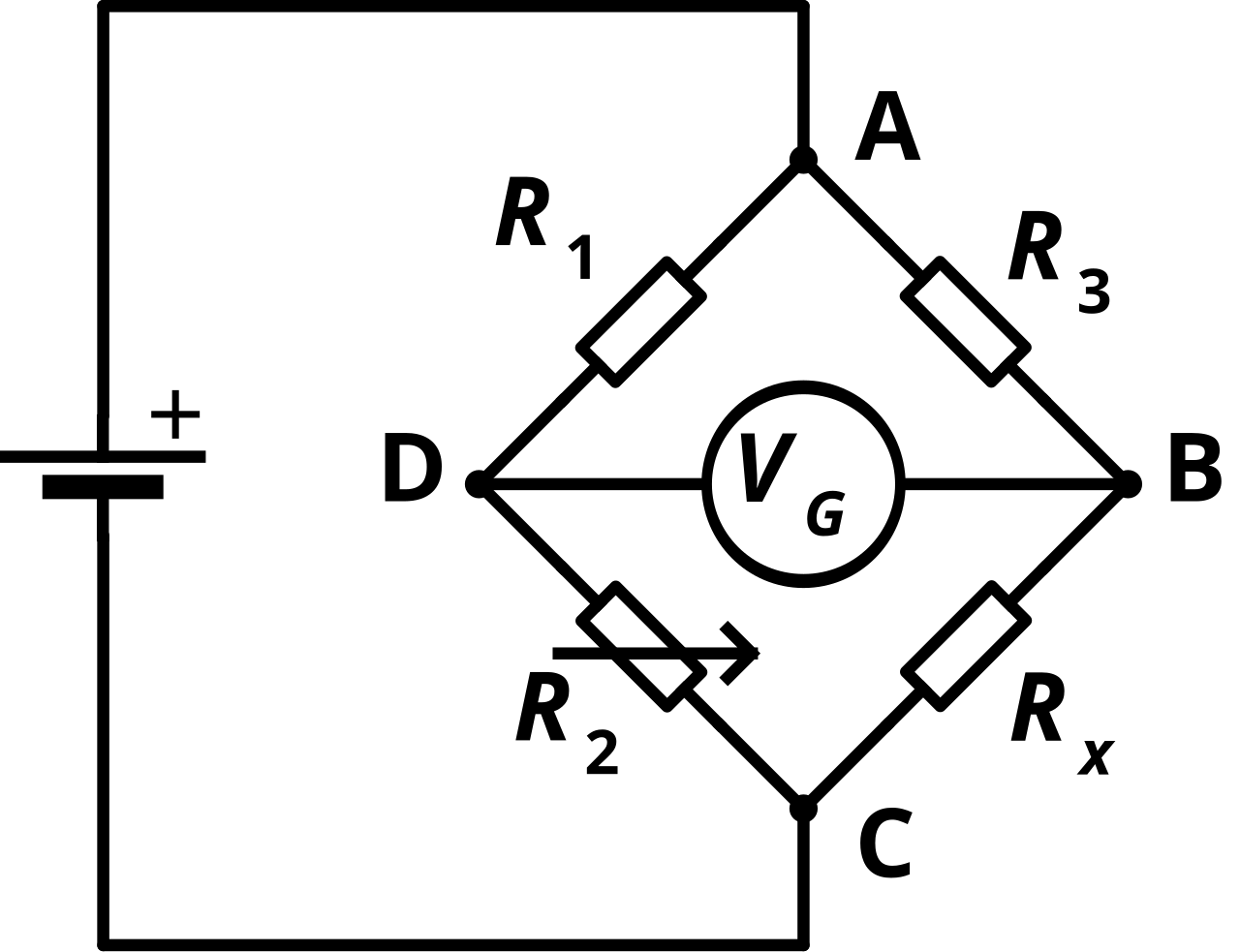

The bridge that makes the difference

This is where the Wheatstone bridge comes in. By combining four resistors — two or more of them active strain gauges — the bridge turns tiny resistance changes into a measurable output. We power the bridge with a stable excitation voltage. When the structure bends, the bridge falls slightly out of balance. That imbalance generates a small but precise output signal, typically in millivolts per volt (mV/V).

Step 1: Choosing the right strain gauge

Everything starts with the gauge itself. At Althen, we supply not only standard strain gauges, but strain gauges for all kinds of conditions and applications — whether you’re working in high temperatures, outdoors in harsh weather, or in a clean lab setup.

To ensure reliable installation, we also provide the right adhesives and protective coatings, as well as cables and connectors for clean signal transmission. Getting these basics right makes the difference between a measurement chain that’s reliable for weeks — or for years.

Various strain gauges

Step 2: Building the measurement chain

Once installed, the strain gauge becomes part of the Wheatstone bridge. But the bridge needs support:

- A stable power supply keeps the excitation voltage clean and steady.

- Proper cabling and connectors ensure that the signal from the gauge isn’t lost or distorted on its way to the electronics.

These accessories may not be the glamorous part of the system, but they are critical for long-term accuracy.

Step 3: Giving the signal a boost

The raw output of a Wheatstone bridge is a whisper, just a few millivolts. That’s where a strain gauge amplifier or signal conditioner steps in.

These amplifiers don’t just boost the signal. They filter noise, stabilize the output, and convert it into standard signals like ±10 V or 4–20 mA — signals that your PLCs, displays, or DAQ systems can actually use.

Step 4: From voltage to real values

At the end of the chain, the amplified signal becomes a usable measurement. In our animation, the dial shows –10 V. In a real-world system, that number might correspond to a truck’s weight, the force on a crane boom, or the pressure in a pipeline.

Real-world applications

We see this complete chain in action every day:

- Industrial weighing: load cells with bonded strain gauges, paired with our inline amplifiers, ensure reliable truck and silo weighing.

- Structural monitoring: rosette strain gauges with protective coatings, combined with conditioners, provide long-term data on bridges and wind turbines.

- Robotics: strain gauges with compact inline amplifiers give robots the force feedback needed for safe gripping.

- Pressure sensors: gauges bonded to diaphragms, combined with conditioners like the TD-SC1, turn pressure changes into precise electrical signals.

Measurement chain

Our customers don’t just need a sensor or an amplifier — they need a working measurement chain. That’s why we deliver the full package: strain gauges, adhesives, coatings, cables, connectors, amplifiers, and conditioners. And, just as important, the know-how to make them work together.

The path from strain to signal

From a strain gauge glued to a surface, through a Wheatstone bridge, to an amplifier that delivers a clean output, it requires the exact right components and expertise.

At Althen, we provide the sensors, accessories, and electronics to build complete measurement solutions you can trust.