In environments where heavy loads, moving equipment, and limited accessibility come into play, wireless force measurement has become more than a convenience — it’s a necessity. Whether you're monitoring a crane on an offshore platform, running load tests in the field, or replacing outdated measurement systems in lifting equipment, going wireless brings freedom, safety, and flexibility.

At Althen, we’ve recently expanded our range of wireless load sensors from LCM Systems, including wireless load pins, load links, and compression load cells. This article explores why wireless solutions are ideal in harsh environments, how they work, and where they make the biggest difference.

When wires get in the way

Traditional weighing systems often rely on cabled sensors. These offer excellent performance in controlled setups, but in dynamic or harsh conditions, cables can quickly become a liability. They may get damaged by moving parts, affected by moisture, or simply be too cumbersome for mobile or rotating equipment.

That’s where wireless weighing systems come into their own. They eliminate the cable and with it, the risk, the hassle, and the limitations.

Instead of sending signals through a wire, wireless load sensors transmit their data via secure radio to handheld devices, displays, USB base stations, or directly into control systems. The result? Real-time measurement of loads without compromising mobility, safety, or durability.

Built for tough conditions

Wireless load sensors are built with ruggedness in mind. Housings are made from stainless steel or aerospace-grade aluminium, and most units are rated to IP67, making them dustproof and waterproof ready for offshore, industrial, and outdoor use.

With internal antennas, protected electronics, and battery lives of 1200+ hours, they’re designed to perform reliably without intervention. Wireless transmission ranges can reach up to 700 meters, making them suitable even for large-scale lifting setups or distributed weighing systems.

Why wireless weighing is ideal for harsh environments

Wireless force sensors are now widely used in industries like marine and offshore, construction, transport, aerospace, and industrial testing. Their ability to function reliably in rugged outdoor environments makes them the go-to solution for applications where conventional wiring is not an option.

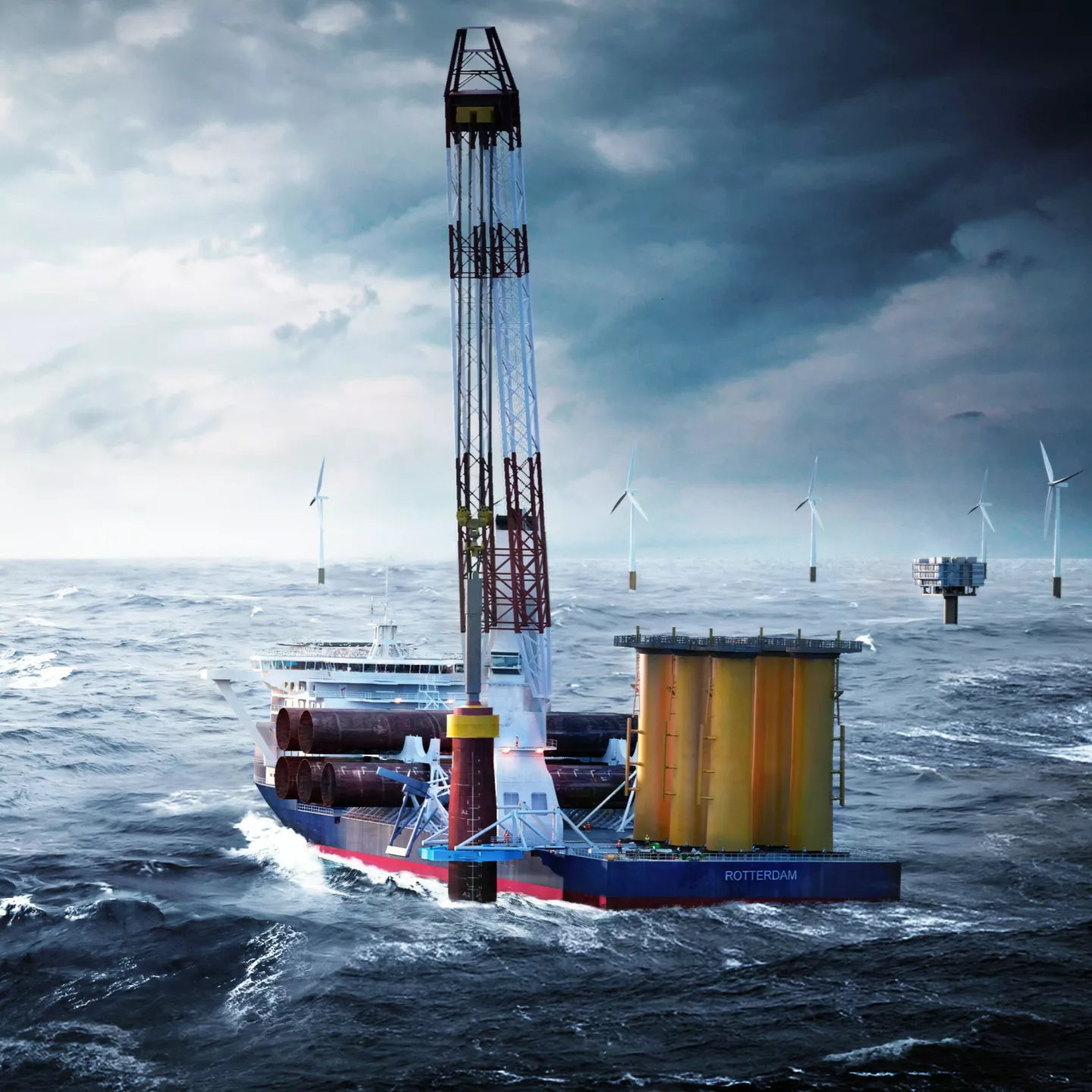

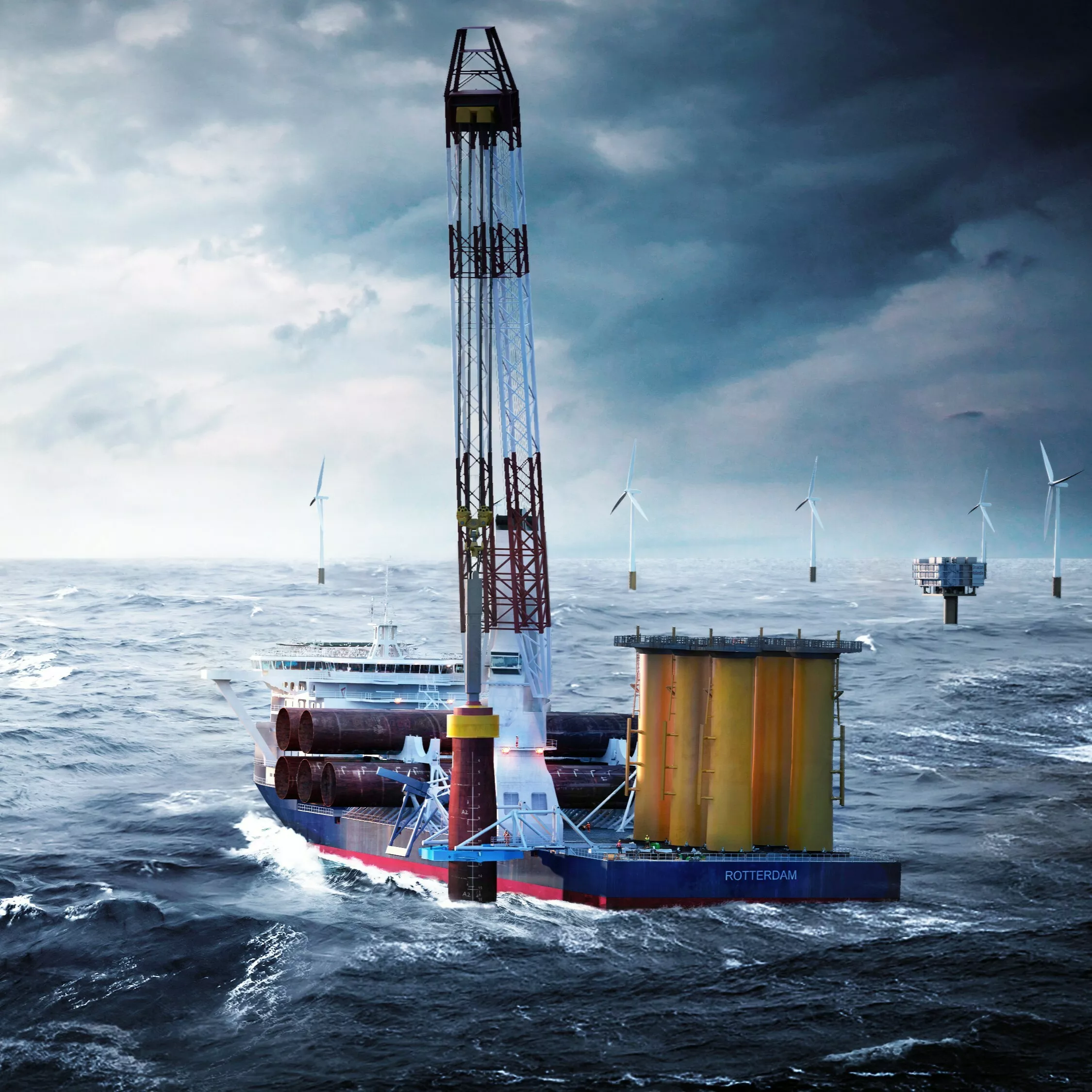

Imagine a crane lifting several tonnes of equipment on a wind turbine installation vessel. There’s constant movement, vibration, saltwater spray, and absolutely no room for trailing cables. A wireless load link like the RILL or WLL provides accurate real-time load data directly to the crew — safely and reliably.

The same applies to structural testing rigs in the field, or mobile lifting gear that needs to be weighed on-site. The flexibility to quickly install a wireless load cell or pin, measure, and move on, saves both time and cost.

Wireless weighing Sensor types

The sensor you choose depends on your mechanical setup and weighing goal. Here are three main types in our portfolio:

Wireless load links

These are placed between shackles or lifting points and are ideal for inline load monitoring during lifting and weighing operations. They are often used during crane overload protection, offshore equipment lifts, or load testing with water bags.

Typical products

Wireless load measuring pins

These replace a structural pin in your equipment and measure shear force directly at the load-bearing point such as a crane pulley, sheave, or winch drum. They’re ideal for retrofit applications or hidden installations.

Wireless compression load cells

These are suited for vertical load measurement in compact spaces or on structural supports. With their low profile, they’re easy to install in tight areas, making them ideal for test benches and support load monitoring.

Typical products

Battery life, range and reliability

Modern wireless force or weighing sensors are designed for long-term field use:

- Battery life: From several hundred hours to over 1200 hours, depending on model and update rate

- Wireless range: Typically 300–700 m line-of-sight

- Environmental protection: IP65 to IP67 for dust, water, and outdoor exposure

- Temperature resistance: Suitable for industrial and marine climates

Internal antennas protect electronics from mechanical damage and environmental exposure.

Integration and data handling

Wireless force sensors can be easily integrated into existing systems:

- Real-time display on handheld units

- Connection to PLCs via base stations and output modules

- Data logging for test reports and certification

- Multi-sensor setups for load distribution or centre-of-gravity calculations

This makes wireless systems suitable for both temporary measurements and permanent monitoring solutions.

When wireless is the smart choice

You don’t always need wireless. But in harsh or mobile environments or when you require operator safety through remote monitoring, it’s often the best or only practical solution.

Choose wireless weighing when:

-

Your installation involves movemente.g., rotating cranes or mobile units

-

You need to avoid cable damageor tripping hazards

-

Setup time is limitede.g., rental or temporary lifting

-

Environment conditionswet, dusty, or offshore circumstances

Weighing without limits

Wireless load sensors are transforming the way we perform weighing and load monitoring in the field. They remove the restrictions of cables while delivering the accuracy and reliability demanded by industrial applications.

At Althen Sensors & Controls, we offer a full portfolio of wireless weighing sensors including custom load pins, wireless load links, and IP67 compression load cells. All engineered to perform in the most challenging environments.

Whether you are building a new system or upgrading an existing one, our experts are ready to help you design the right wireless solution.