Reliable detection of ground motion

Even small ground movements can have major effects on buildings, bridges, and industrial installations. Continuous vibration or minor seismic activity can lead to cracks, fatigue, or misalignment over time.

With seismic sensors, these movements become measurable. They capture ground acceleration and vibration with high precision and enable early detection of potential structural issues. This supports safety, maintenance planning, and operational reliability.

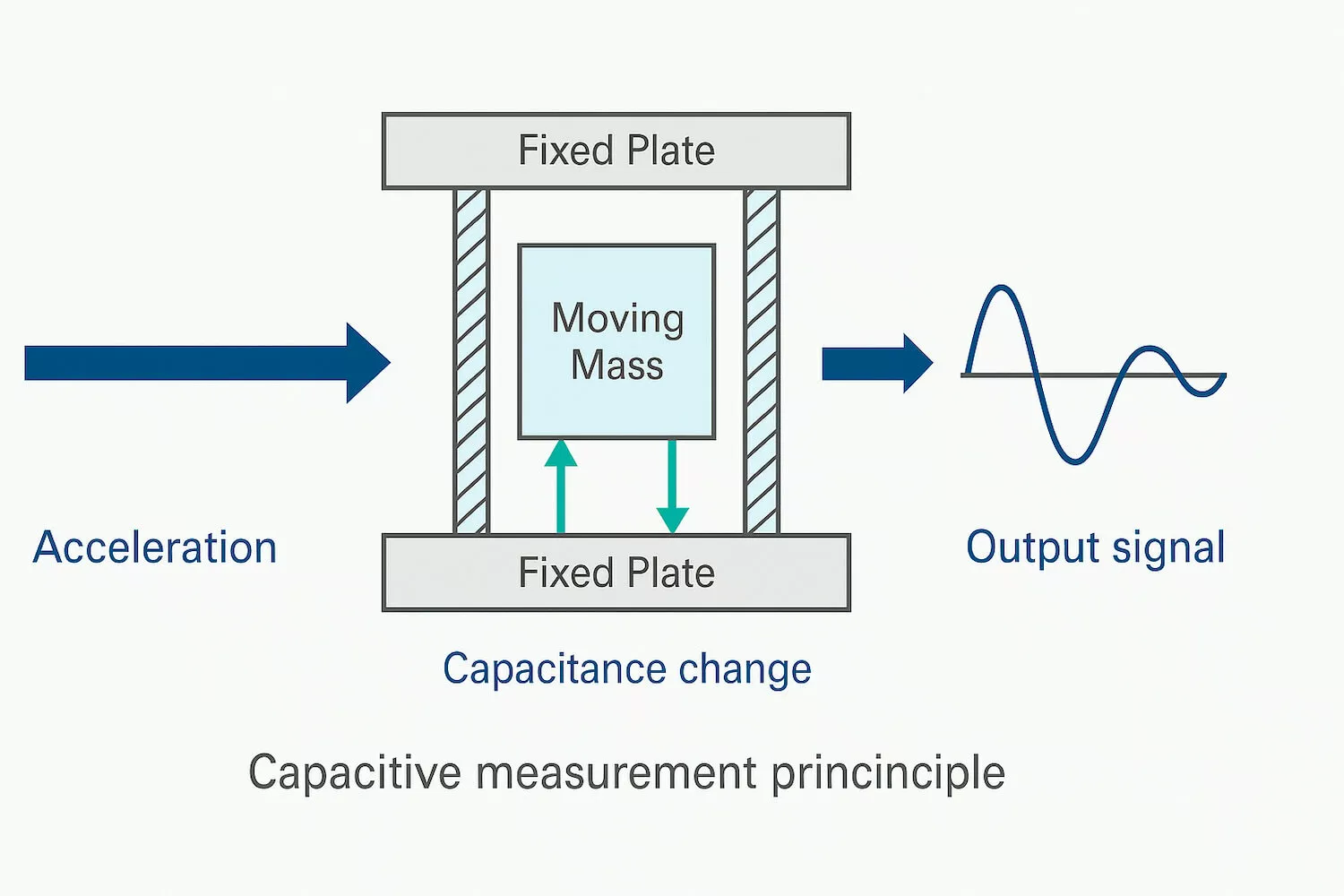

How capacitive MEMS seismic sensors work

The ASC EQ Series uses capacitive MEMS technology to detect ground motion. The sensor contains a small moving mass between two fixed capacitor plates. When acceleration occurs, the mass moves slightly, changing the capacitance. This change is converted into an electrical signal — the basis for accurate vibration measurement.

Key performance details

- Measurement range: typically ±3 g or ±5 g

- Noise performance: up to ~113 dB signal-to-noise ratio (at ±3 g)

- Frequency range: optimized for low frequencies (0–20 Hz), extended up to 100 Hz

- Resolution: better than 1 µg (one-millionth of gravity)

This combination makes the sensors suitable for both structural health monitoring and earthquake early warning systems. With low noise and fast response, they provide reliable data even in environments with minimal vibration levels.

Where seismic sensors are used

Site assessment and safety evaluation

During planning and construction phases, vibration monitoring provides real data on soil stability and environmental impacts. This helps engineers to design structures that are resilient to both local and regional seismic activity.

Earthquake and ground motion monitoring

Seismic sensors form part of permanent observation networks that record small and large earthquakes worldwide. With more than 9,000 micro-earthquakes per day, continuous measurement supports risk analysis and infrastructure safety.

Two other applications for seismic sensors

Site assessment and safety evaluation

During planning and construction phases, vibration monitoring provides real data on soil stability and environmental impacts. This helps engineers to design structures that are resilient to both local and regional seismic activity.

Earthquake and ground motion monitoring

Seismic sensors form part of permanent observation networks that record small and large earthquakes worldwide. With more than 9,000 micro-earthquakes per day, continuous measurement supports risk analysis and infrastructure safety.

Engineering considerations

Calibration and signal drift

Accurate long-term measurements require regular calibration and verification. Drift compensation ensures that data remains stable over time.

Environmental effects

Temperature variation, humidity, and electromagnetic noise can influence readings. Proper housing and signal filtering are therefore essential in demanding environments.

Data handling

Reliable monitoring systems depend not only on hardware but also on the way data is processed. Effective filtering, data fusion, and smart algorithms turn vibration data into actionable insights.

Avoiding false alarms

Overly sensitive detection can cause unnecessary alerts. Correct sensor placement, threshold setting, and redundancy improve reliability and operational trust.

Seismic sensors

Discover our low frequency vibration sensors

ASC EQ-x211 / EQ-x215 Low-frequency capacitive MEMS accelerometer

- Sub-μg resolution MEMS sensor

- Triaxial seismic accelerometer

- Optional IP68 for harsh environments

ASC QF-1211 Low-frequency seismic vibration sensor

- Low-frequency seismic vibration sensor

- Bandwidth DC to 200 Hz, noise density 7 µg/√Hz

- IP67 aluminium housing, ±1 g to ±10 g ranges

Engineer’s summary

Seismic sensors make the invisible visible. They help engineers understand how structures behave under stress — and act before damage occurs. With precise measurement and proper integration, these sensors become a core element of preventive maintenance and structural safety.