More simple, reliable and cost-effective weighing stations

In the process of weighing goods, the smallest mistake can have big consequences. In most production processes, more and more individual components of products have to be weighed, whether to determine mixing ratios or to package products. Small errors in weighing can quickly add up and cause high follow-up costs or - if the mixing ratios are wrong - can even make products useless in the end. For this reason, systems that work with small product weights are often constructed in a complex and expensive way. However, there are certainly possibilities to design such weighing stations more simple, reliable and cost-effective.

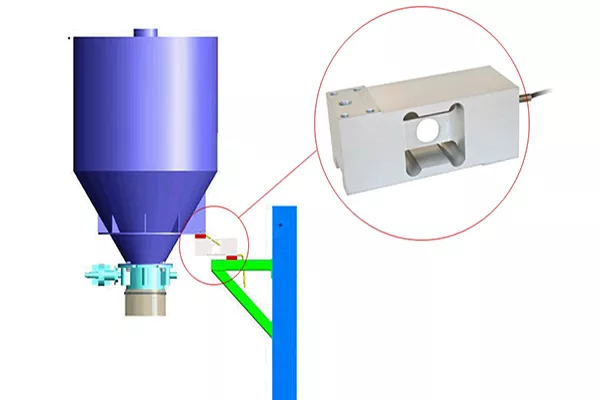

Hanging instead of setting up

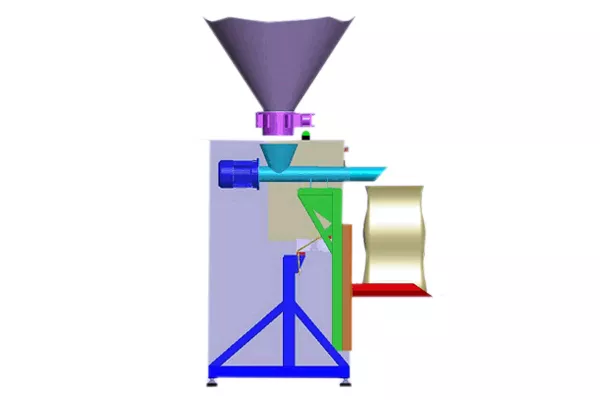

Instead of weighing small containers with several load cells, this can also be done with one single load cell. For this purpose, the filling container is hung on the load cell and not, as is often the case, placed on several load cells. This method also eliminates the expense of connecting several load cells in parallel. The additional elimination of cabling and installation times as well as material costs creates efficient and cost-effective solutions.

Tailor-made solution for every requirement

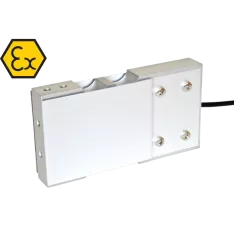

To select the right sensor for your application and to achieve the required accuracy, the relation of the total weight of the dosing unit to the smallest dosing weight must be correct. This depends, among other things, on the application itself and therefore must be checked individually. For small weights single-point load cells are suitable, for larger weights so-called shear beam loadcells are used. The transducers are generally easy to install, as they are designed as platform load cells and thus achieve their accuracy within the range of the specified platform size.

Calibration of the load cell

In any case, the load cell used should be calibrated regularly, as this is the only way to ensure the accuracy of the dosing process permanently and reliably. If the system is designed for sales (e.g. weighing of packages), the load cells used must be calibratable (C3). Althen offers you a repair and calibration service as well as corresponding C3-capable load cells. The transducer signals are evaluated by means of downstream evaluation electronics, either with analog signals or digitally via an industry-standard bus interface.

Retrofitting of existing plants

Even systems that already work by "setting up" the filling containers on several load cells can be retrofitted to the new method. This makes particular sense if a part of the existing measuring chain is defective or parts are no longer usable after modernisation measures. Althen's load cells, weighing transmitters and indicators are suitable for industrial automation, the chemical and pharmaceutical industry, the food sector as well as the automotive and packaging industry.

Related products

AF Single Point Load Cell

- Measuring range: 5, 15, 50kg

- Special steel construction

- Combined error ≤ ±0.05%

AU Single Point Load Cell

- Measuring range: 3 to 15 kg & 30 to 50 kg

- Aluminium alloy construction loadcell

- Combined error ≤±0.02%