Smart tram monitoring in The Hague with Althen’s 3D Wheel+ System

Automated, contactless 3D wheel measurement system for rail vehicles. Suited for high-speed and low-speed environments. Collects accurate geometric wheel data without stopping trains.

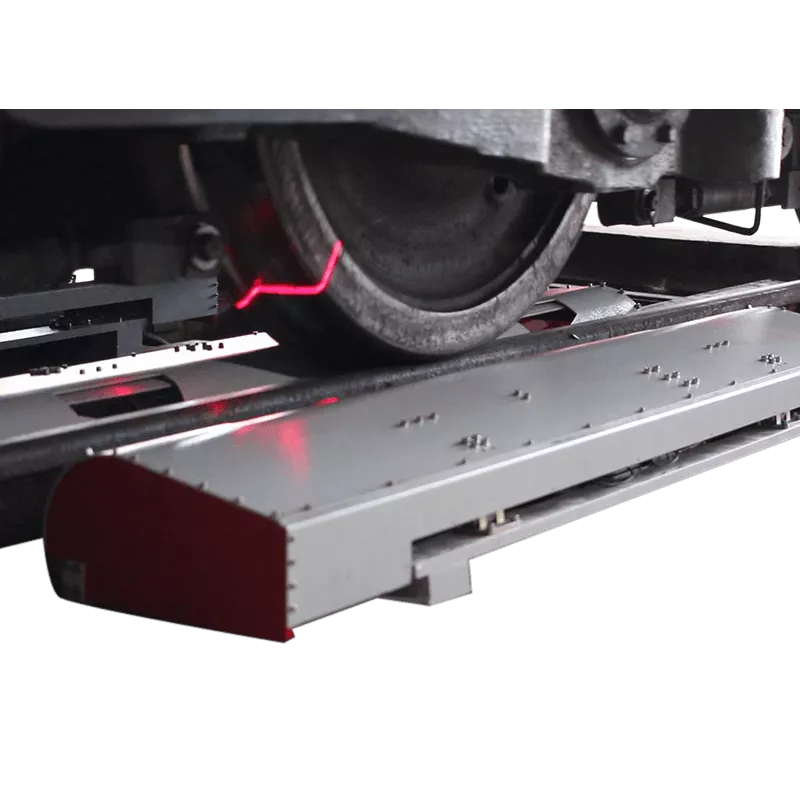

The 3D wheel measurement system is an automated, contactless solution for accurate railway wheel inspection. It is designed for continuous condition monitoring of wheels on trams, metros, trains and light rail vehicles. Using advanced laser scanning technology, the system captures a full 3D wheel profile while the vehicle is in motion. There is no physical contact with the wheel. There is no need to stop the train.

This makes the system ideal for modern railway maintenance strategies focused on safety, availability and cost control.

The system uses high-speed laser sensors to scan each wheel as it passes the measurement point. The lasers generate a precise three-dimensional model of the wheel geometry. From this 3D model, all relevant wheel parameters are calculated automatically.

This includes wheel diameter, tread wear, flange height and flange thickness. Because the measurement is contactless, there is no mechanical wear on the system itself.

Measurement accuracy remains stable over time.

The 3D wheel measurement system works while the vehicle is moving. Measurements can be performed at operational speeds. This reduces inspection time and avoids bottlenecks in depots or workshops. Trains do not need to be taken out of service for manual checks. The result is faster inspections and higher fleet availability.

The system delivers high measurement accuracy, up to 0.05 mm, depending on configuration. Each wheel is measured consistently, independent of operator influence. This repeatability makes the data suitable for long-term trend analysis.

Wear patterns can be tracked over time for predictive maintenance.

The 3D Wheel Measurement System can be installed in 3 variants:

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expert| Specification | Value |

|---|---|

| Back-to-back gauge (accuracy) | ± 0.05mm |

| Flange angle (accuracy) | ± 0.1mm |

| Flange height (accuracy) | ± 0.1mm |

| Flange width (accuracy) | ± 0.1mm |

| Rim thickness (accuracy) | ± 0.1mm |

| Thread width (accuracy) | ± 0.1mm |

| Wheel diameter (accuracy) | ± 0.2mm |

| Wheel profiles (accuracy) | ± 0.1mm |