11 August 2022

Hoe snel beweegt lucht, wat doen verschillende windomstandigheden met windturbines en hoe helpt kennis over luchtdruk bij het vinden van de optimale rotorgeometrie? Op Windenergy 2022 in Hamburg zal Althen verschillende toepassingen van meettechniek in de windindustrie laten zien. Net als offshore-toepassingen en hernieuwbare energiebronnen in het algemeen, is aerodynamica al heel lang een belangrijk thema voor de sensor- en meettechnologie experts van Althen.

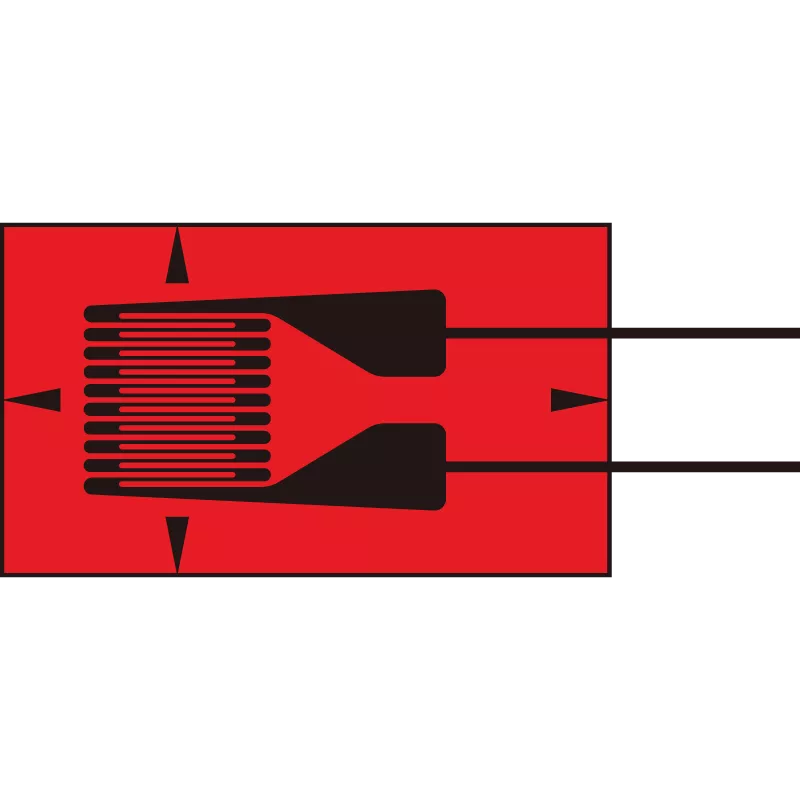

Wanneer een rotor begint te draaien wordt grotendeels bepaald door geometrie. Bij het ontwerp van rotoren wordt gewerkt aan een steeds betere benutting van de beschikbare luchtstroom. Voor het meten van de rotorbladen en het gedrag van de luchtdruk als functie van de rotatiesnelheid en de luchtsnelheid, is de MPS-drukmetingstechnologie (multiple pressure scanner) de ideale oplossing. Drukscanners helpen de aerodynamica te optimaliseren. Daartoe worden kleine gaatjes in het rotorblad gemaakt. Op deze gaten zijn luchtslangen aangesloten via drukpatches, die op hun beurt zijn verbonden met de MPS4264. De Althen drukscanner MPS64 meet kleine tot middelgrote druk (4 millibar tot 3,5 bar) met een zeer goede nauwkeurigheid van maximaal ±0,04 %. De 64 meetkanalen zijn ondergebracht in een behuizing die nauwelijks de grootte heeft van een pakje sigaretten. De MPS64 heeft een Ethernet-interface voor cascadering. Via een schakelaar is het mogelijk een willekeurig aantal scanners aan te sluiten. De sensortechnologie is ontworpen voor temperaturen van 0 - 70 °C. Een thermische beveiligingsbehuizing maakt werking mogelijk, zelfs bij vorst of hogere temperaturen.

Coördinatenstelsel van de lucht

Berekeningsmodellen raken aan hun grenzen wanneer het gaat om concrete aërodynamische omstandigheden. Bijvoorbeeld tussen de diverse turbines van een offshore-windmolenpark. De turbulenties die hier ontstaan kunnen het best in kaart worden gebracht met een driedimensionaal luchtsnelheidsmodel.

Hierbij wordt een drone uitgerust met een microluchtgegevenscomputer en een pitotsonde met 5 gaten (pitch-yaw probe). De luchtsnelheid wordt gemeten op vaste afstanden/meetpunten. De compacte Micro Air Data Computer verwerkt met behulp van de sonde verkregen meetgegevens en gebruikt algoritmen om windsnelheden en windrichtingen (vectoren) te genereren. Door de meetresultaten van elk meetpunt te combineren, kan vervolgens een 3D-beeld worden gegenereerd.

Grotere installaties, Meer metingen

Spanningsmeters zijn veelzijdig. Overal waar rotatie, torsie of andere bewegingen in structuren optreden, kan met deze meetmethode schade in een vroeg stadium worden opgespoord. In een windturbine, van de statica in de basis tot de helling van de toren en de versnelling van de generatorkoepel, is praktisch geen enkel element onaangetast door constante beweging. Tegelijkertijd vereist de ontwikkeling naar steeds grotere windturbines steeds meer metingen.

Bij onderzoek wordt de procedure ook gebruikt met rekstrookjes om het gedrag van nieuwe materialen te testen. Vooral in composieten, waar kunststof en metaal elkaar ontmoeten, ontstaan kritische punten waarvan het spanningsniveau met rekstrookjes kan worden bepaald.

Bezoek van 27 t/m 30 september tijdens WindEnergy 2022 in Hamburg. Wij staan in Hal B7.FG op Stand 007.