Automated stress analysis boom cranes

Link-Belt Constructios Equipment of Lexington, Kentucky, wanted to perform a quality check in the form of an automated stress analysis for its new telescopic and lattice boom cranes. The company's test engineers must perform various static and dynamic checks on the cranes to match the designs with the given specifications in terms of safety, reliability and overall performance. In case of critical deficiencies, modifications can be made to the designs in a timely manner.

The challenge

For this purpose, a robust, customer-specific data acquisition system had to be created that is insensitive to weather conditions, has simple operability and can also be used for changing requirements. It had to provide multiple inputs for different sensor types, such as strain gauges, and have an open architecture to allow the user interface to be adapted to the engineers' requirements. Further requirements were high reliability and durability as well as compatibility with the existing software and a favorable price.

The measurement solution

This project required a combination of the customer's preferred method of software control with Gantner's standard components in order to be able to carry out all the planned tests. With the Q.series product line, Ganter was able to offer a wide range of options here. In addition, individual housings for each of the decentralized systems could be provided to the customer.

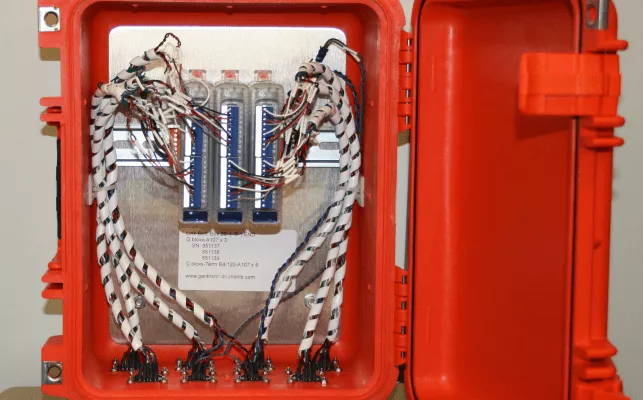

As the effort required for data acquisition at each measuring point of the crane boom was high, the decision was made in favor of a decentralized approach. A total of 30 data acquisition systems were installed, each with three A107 modules with a total of twelve channels for 120-ohm quarter-bridge measurements per system. Each of the systems was installed in a custom-built, weatherproof enclosure. The Q.pac DL test controller from Gantner Instruments' Q.series product line handled the processing of the 360 channels for the strain measurements. The four UARTs of each Test Controller Q.pac could handle up to twenty enclosures, or five enclosures per UART. A total of six UARTs were required.

Within twelve weeks

The controller collects and stores the data, which is then read by the LabVIEW application in real time. The software's interface is modeled after the software already used by Link-Belt Construction Equipment to make the transition as easy as possible for engineers. In addition, the programming architecture is designed for possible future extensions, additions and developments - making it compatible with future operating systems. Gantner's software package enables strain gage (SG) configuration and visualization, live value acquisition, saving of test details, zero values, pausing/resuming tests, creating custom comparison screens, and generating detailed test reports. This entire application with hardware and software, was completed within just 12 weeks after order placement.

Produkte

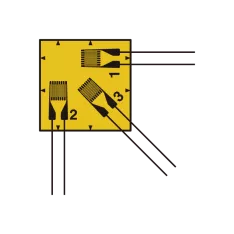

QFRAB Series High Temperature Use Strain Gauges

- Strain limit 3% (30000×10⁻⁶ strain)

- Operational temperature: -20~+200°C

- 3-element 0°/45°/90° stacked type