The Nixus research project

The Nixus research project is a key project of WARR Rocketry, the Scientific Working Group for Rocket Technology and Spaceflight at the Technical University of Munich. WARR Rocketry is the oldest student spaceflight group in Europe and brings together more than 150 students from a wide range of disciplines.

Nixus is a bi-liquid, cryogenic high-altitude research rocket powered by liquid oxygen (LOX) and ethanol. The goal is to reach a target altitude of 9,000 meters as precisely as possible in international competitions such as the European Rocketry Challenge (EuRoC) – a special technical challenge that requires exact mass calculation, fuel metering, aerodynamic optimization, and precise flight control.

In addition to the competition goal, the project has a clear research and educational mission: It enables students to develop and implement complex space technologies in a practical way – from design and manufacturing to testing and post-flight data analysis. The name “Nixus” is derived from the mythological figure Nixus and symbolizes drive, dynamism, and the tireless urge to reach new heights.

From CFRP vision to hybrid solution

At the start of development, the team pursued the ambitious goal of creating a high-pressure tank for Nixus made entirely from CFRP. This solution promised an optimal balance of weight, strength, and temperature resistance and would have broken new ground in the European student environment. The first prototype test of the new CFRP tank design initially involved a leak test to ensure the complete integrity of the components. This was followed by a destruction test to determine the load limits of the system. In this phase, Althen sensors were also integrated into the test setup for the first time in order to obtain precise measurement data for further development.

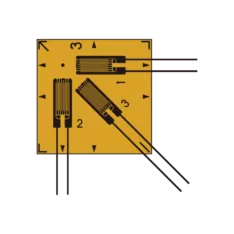

Althen's BFRAB-5-5-5LJCT-F strain gauges are used for structural monitoring of CFRP tanks and the associated mechanical loads. This foil strain gauge is characterized by its compact design, high measuring accuracy, and temperature compensation, making it ideal for use under the extreme conditions of a rocket launch. Its robust construction allows operation under strong vibrations, high accelerations, and significant temperature fluctuations, such as those encountered in cryogenic propulsion systems. In the Nixus project, the strain gauges are specifically attached to highly stressed areas of the CFRP tank structure in order to collect precise data on strains, stresses, and potential structural deformations during testing. This information is crucial for further optimizing the design, identifying material reserves, and ensuring the long-term reliability of the tanks.

Technical difficulties

However, repeated technical difficulties arose during testing, particularly with regard to tightness and structural stability under cryogenic conditions. Despite several attempts at optimization, the pure CFRP design could not be reliably brought to the desired operational maturity.

In order to still be able to participate in the competition and ensure flight operations, the team decided with a heavy heart to resort to an aluminum-CFRP hybrid solution. In this solution, an aluminum structure takes on the primary load-bearing function, while CFRP elements provide weight savings and additional strength. This variant proved to be practical and formed the basis for the successful EuRoC launch.

Parallel to this interim solution, the development of the pure CFRP tank was not abandoned, but rather pursued with the goal of becoming the first European student team to fly a functional, pure CFRP tank in the next competition.

Accept the marketing cookies to view this video.

Click here to change your consent.

Competition success at EuRoC 2024

On October 14 at 6:00 p.m. local time, the rocket was successfully launched – the first bi-liquid cryogenic rocket built by students in Europe. This success led to three awards:

- Team-Award – for outstanding cooperation and efficient processes.

- Payload-Award – for the best self-built experiment on board.

- L3-Award – for the best flight in the “Biliquid” category.

Outlook – Motivation & next steps

The clear success of Nixus and EuRoC inspires us to be the first European student team to use CFRP tanks in a rocket again next year – with increased robustness and enhanced measurement and structural technology, and of course a completely new, innovative tank.

Products for this project

BFRA Series Strain Gauges for Composite Material Use

- 3-element 0°/45°/90° plane type

CN-Y adhesives (Post-yield)

- Easy-to-use

- Suitable strain gage series: YF and YEF

- Suitable materials: Metals, CFRP, GFRP and Plastics