Author: Robert Wagner, CPVD Lead | Projekt Nixus | WARR Rocketry

About the project

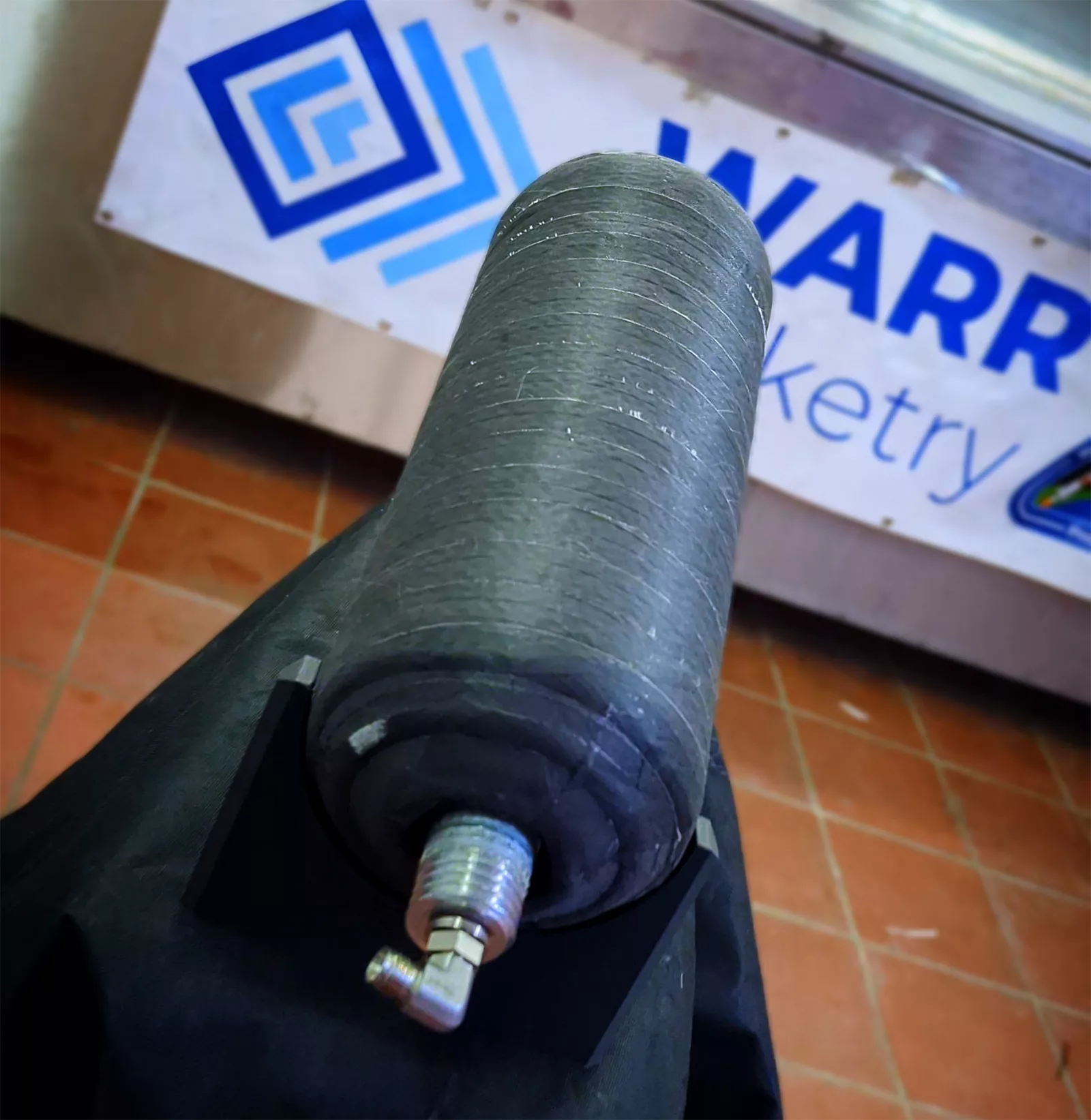

The student space team at the Technical University of Munich – WARR – develops innovative high-altitude research rockets and conducts research into, among other things, so-called “Type V composite pressure tanks.” This groundbreaking technology promises lightweight tanks without inner liners, but poses major challenges in terms of safety, simulation, and resilience. The use of high-precision strain gauges makes it possible to record the failure behavior of these full-carbon tanks in detail, thus making the underlying simulations for composite materials more efficient and reliable.

Type V composite fuel tanks

The special feature of Type V tanks is that they are very light yet pressure-resistant. However, they are particularly susceptible to:

- Micromechanical defects (e.g., cracks in the fiber matrix)

- Permeation (gases penetrate the material more easily)

- Material fatigue under high pressure or extreme temperatures

At the same time, the anisotropic (direction-dependent) structure of carbon composites makes it difficult to accurately simulate failure behavior. Conventional calculation models quickly reach their limits because the interaction of fiber orientation, matrix behavior, and possible microcracks is difficult to represent realistically.

To close this gap between theory and practice, WARR relies on experimental burst strength tests on prototype tanks. This requires high-precision strain gauges to record the material behavior in detail and then incorporate it into the simulations in order to improve them.

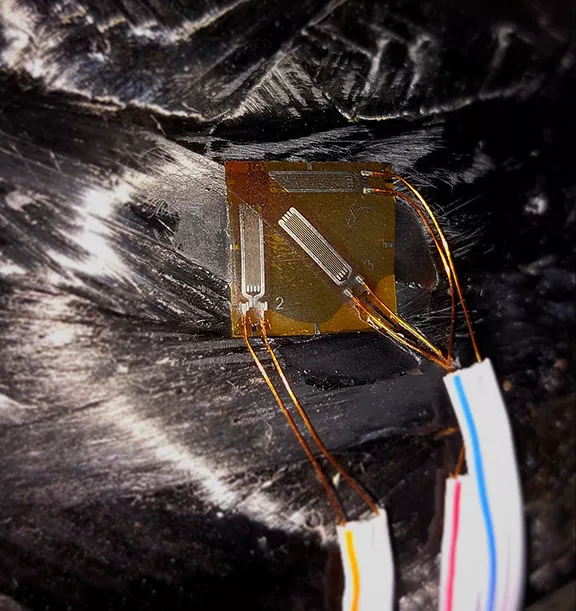

Composite-optimized strain gauges

In order to measure both axial and radial strains and potential off-axis loads during rupture, the team opted for BFRAB-5 strain gauges. These gauges offer:

- Large measuring area specifically for composite materials

- Reduced temperature influences thanks to coordinated material properties

- Multidimensional analysis thanks to rosette configuration (detection of axial and circumferential strain as well as 45° off-axis data)

This allows the failure behavior of composite structures to be observed with high precision. The measurement curves not only show when and how the material yields, but also provide clues to critical areas where microscopic cracks first occur.

From production to evaluation

The manufacture of Type V tanks using the winding process is complex and requires the highest precision. Similar to classic prepreg processes, manufacturing defects such as inclusions or dry spots can occur. Especially with pressure tanks, it is therefore crucial to thoroughly test and evaluate these structures in order to ensure maximum safety.

In contrast, the application and reading of the strain gauges proved to be surprisingly straightforward. The strips could be applied quickly and reliably using the adhesive and accessories supplied. The customer-specific, freely selectable length of the measuring cables proved to be particularly practical, as it made installation considerably easier. This enabled a smooth and efficient measurement campaign overall.

Measurement results and outlook

The precise measurement data enabled us to understand the material behavior in detail and optimize the tank structure step by step. In particular, taking into account the anisotropic properties of carbon fibers led to valuable insights that were incorporated into the design. In September 2025, we were proud to present our first full-scale Type V tank – with an empty weight of only 2.3 kg.

This result marks an important milestone for our team and demonstrates the potential that innovative measurement technology offers for the further development of high-performance composites.

Participation in the Nixus rocket project

After setting a European record last year—as the first student-built bi-liquid cryogenic rocket—we are competing again this year in Portugal at the European Rocketry Challenge (EUROC). There, we will be using an advanced system. Compared to the aluminum alternative, the Type V tank enables a weight reduction of around 50%, thereby significantly increasing the performance of our rocket.