About the project

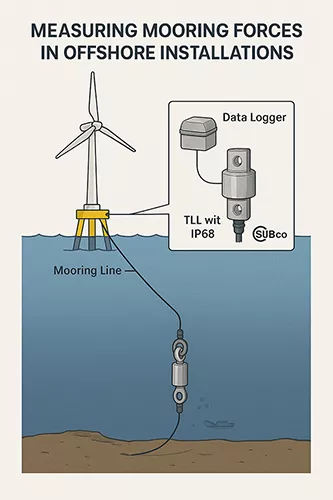

A leading institute for polar and marine research is currently conducting research on mooring forces in offshore installations. This project involves implementing a measurement system to monitor mooring forces in offshore structures. The aim is to record the dynamic loads caused specifically by wave motion at the mooring points under real environmental conditions over a longer period of time. The aim is to gain insights into the structural safety and optimisation of mooring systems.

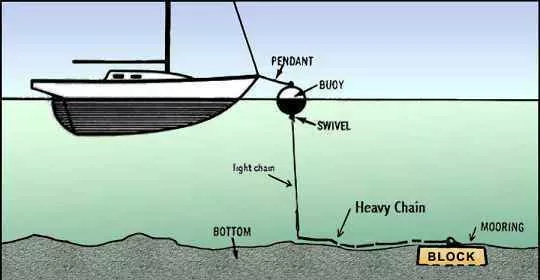

What is mooring?

Mooring refers to the anchoring system used to secure floating offshore structures such as wind turbines, platforms or measuring buoys to the seabed. It usually consists of anchor lines, chains or ropes that are connected to the structure via connecting elements. The purpose of mooring is to keep the structure stable despite wind, waves and currents and to prevent uncontrolled movements. The design of such systems requires precise knowledge of the tensile forces that occur, especially under extreme environmental conditions.

Challenge posed by high wave loads in offshore applications

Very high waves pose a considerable challenge for offshore installations, as they generate extreme dynamic loads on the mooring lines. These loads fluctuate greatly and can lead to overloading or material fatigue – especially in the case of continuous wave action over long periods of time. In addition, the direction of pull changes constantly due to the up and down movement of the platform, which necessitates precise force measurements to ensure the structural integrity, safety and long-term availability of the installation. Especially in rough sea areas such as the North Sea, such loads are critical for the design and monitoring of mooring systems.

Product used

An Althen TLL tensile force sensor, specially designed for offshore applications and integrated into a pressure-tight IP68 housing, is used to monitor the mooring forces. A robust SUBCon connector is used for the electrical connection, enabling secure underwater disconnection. Data is recorded by an autonomous data logger with a runtime of 30 days, which is replaced at regular intervals by a diver to ensure complete recording of the measurement data.

Project implementation

The sensor was integrated directly into the mooring connection of a floating offshore structure and connected to the data logger via the SUBCon plug connection. The entire unit was housed in a corrosion-resistant stainless steel enclosure, enabling long-term underwater use. Monthly maintenance by divers allows the data logger to be easily replaced without dismantling the underwater components – a decisive advantage for continuous operation under demanding maritime conditions.

Althen Sensors & Controls supplied the complete system, including consulting, logger solution and mechanical adaptation to the underwater environment.

About the TLL traction sensor

The TLL tensile force sensor from Althen was specially developed for precise force measurements under extreme offshore conditions and offers a reliable, long-term solution for monitoring mooring forces. Its housing is made of corrosion-resistant 17-4PH stainless steel and is ideal for permanent use in maritime environments. With a wide measuring range from 1 to 1000 tonnes, the sensor can be flexibly adapted to a wide variety of load scenarios.

Technical highlights:

- Compact design: Ideal for integration in limited installation space

- High accuracy: Measurement accuracy of up to ±0.3% of the final value

- Reliable signal transmission thanks to hard-wired design

- IP68 stainless steel housing for pressure-tight underwater use

- Strain gauge-based measuring principle for proven precision

In addition to its technical performance, the TLL sensor also impresses in operational use with its high maintainability and reliability. The use of a SUBCon plug connection allows the housing to be disconnected quickly and without tools underwater – a decisive advantage for regular maintenance intervals. In combination with an autonomous data logger that has a runtime of 30 days and operates without an external power supply, the result is a particularly robust and efficient measurement system. This makes the sensor ideal for integration into offshore structures where durability, minimal downtime and precise data availability are of central importance.