Project March

Project MARCH is a project at the TU Delft where each year a new team of 27 students comes together to develop, build and test an exoskeleton. This device allows people who cannot move their lower extremities due to a spinal cord injury to stand up and walk again.

One of the biggest challenges for exoskeletons at the moment is standing and walking self-balanced, i.e. without requiring the pilot to use crutches. In order to achieve this, it is crucial to know the loads acting on all joints of the system. This proves to be quite challenging to achieve in the rotational joints used in the exo, as these need to be both robust and compact and offer only little design space.

Difficult to distinguish axial loads from off-axis loads

The last two years, Project MARCH and Althen collaborated on integrating a sensor into one of the parts of the joint while keeping the changes to said part and the whole joint to a minimum, however this made it very difficult to distinguish axial loads from off-axis loads. This year Althen helped with 6 ATF336-Z 360Nm Static torque sensors, and 2 ALF255-Z5398-3KN-Digital output RS485 Miniature diaphragm loadcells.

Accept the marketing cookies to view this video.

Click here to change your consent.

Torque sensor selection and integration criteria

As the F336 style sensor was already chosen the years before based on the expected load cases, we stuck with this. We also kept the range at 360 Nm. Further important requirements were a significant difference in the magnitude of axial and off-axis loads, as well as the sensor fitting into the rather small design space and being able to be easily integrated in the pre-existing actuator design.

Seamless sensor integration and testing

After a collaborative design process, we ended up with disk-shaped torque sensors that could easily be integrated in our rotational joints. This allowed us to include the installation and initial testing in our normal process of assembling, testing and installing joints into our exo. During initial testing, the torque values provided by the sensor were verified and initial tests were done to quantify the magnitude of off-axis loads, which also showed very promising results.

Sensors used in this project

Reaction torque and miniature force sensors

ATF326 Reaction Torque Sensor

- Measuring range: 0 - 20 Nm

- -10 - +80 °C Operating temperature

- Hysteresis: ±0.4 % RT

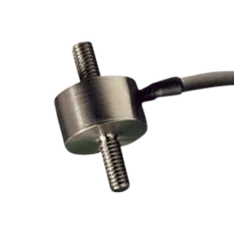

ALF255 Miniature Force Sensor

- Measurement ranges: up to 6.4 kN

- Versions operating up to +250°C possible

- ø30mm x 25mm body

Improved off-axis load detection marks key milestone

This iteration of the torque sensors definitely seems to be more reliable, especially regarding off-axis loads. If this is the case in the end this would mean a huge step for us on the way to achieving self-balanced standing and walking. We are very thankful for all the help from Althen with their expertise and time that they provided.