In a current research project, the Bundesanstalt für Wasserbau in Karlsruhe (BAW) is investigating the factors influencing the load-bearing capacity of grouted anchoring elements. Grouted anchoring elements are used to anchor structures securely in soil or rock. They provide a force-fit connection between a structure and the subsoil by permanently fixing them by injecting cement, cement paste or other injection materials, for example.

Areas of application for anchoring elements:

- Excavation support

- Slope, bank and rock stabilisation

- bridge construction

- Foundation reinforcement

- Dams and reservoirs

What are grout bodies and grout anchors?

A grouted anchor is a special type of anchor that is used to fasten structures in soil or rock. It consists of an anchor head, an anchor tension member (e.g. prestressing steel or strands) and an anchor body grouted into the ground. A borehole is drilled into the ground or rock for installation. The anchor is inserted and grouted with a cement paste, cement mortar or injection resin (grout body). Once the grout has hardened, the anchor can be tensioned and loaded.

The grout body forms the solidified section of the grouted anchor. The injection of cement paste, for example, creates a firm bond between the anchor and the ground, which ensures optimum load transfer.

Image source: Bundesanstalt für Wasserbau (BAW)

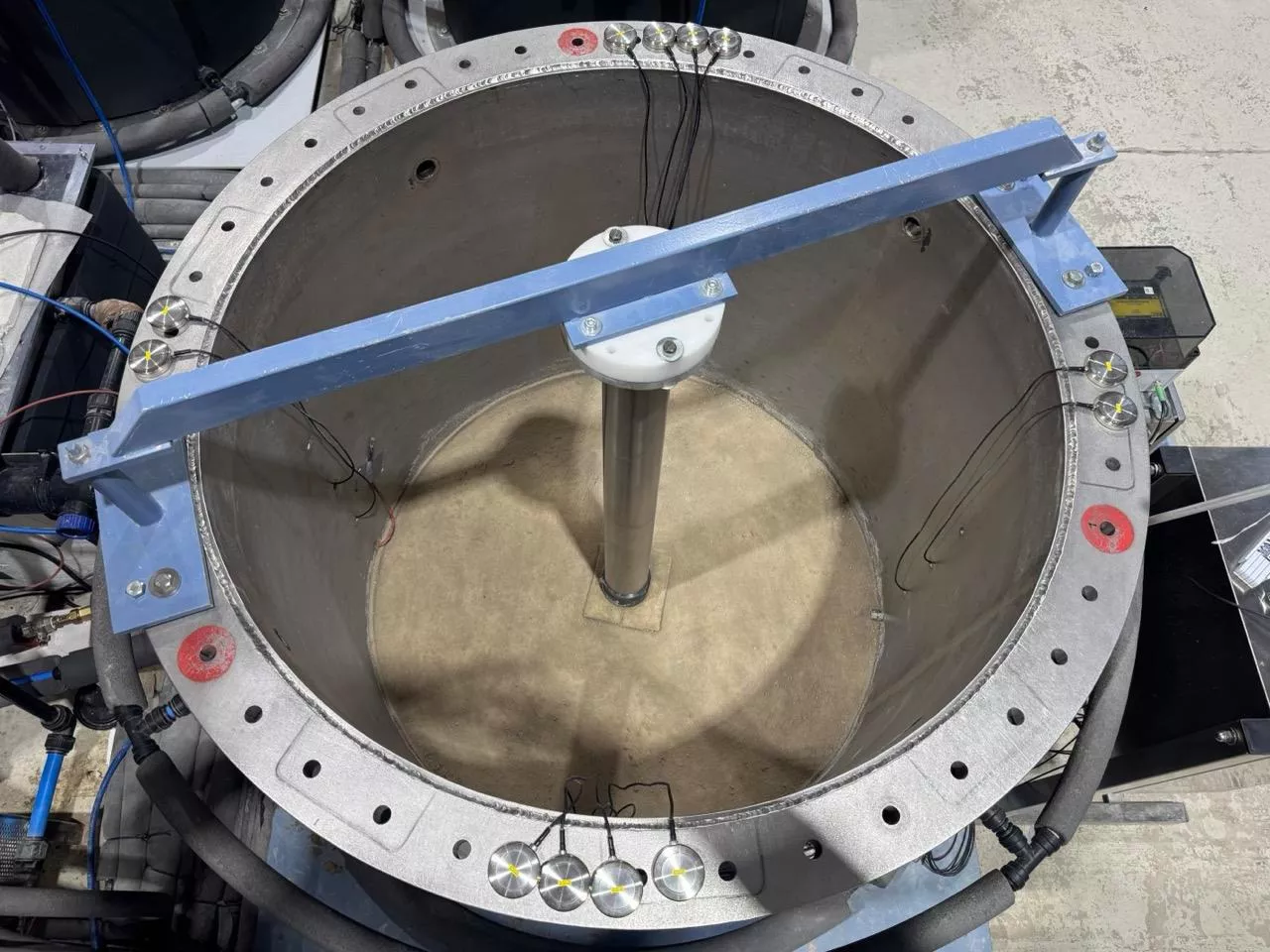

Experiment setup

Small-scale model tests are carried out to test the influencing variables on the load-bearing capacity of grouted anchoring elements. The tested grouted elements are made of cement paste and have a diameter of 90 mm, including a steel reinforcement. The soil structure for these tests is fine and medium sand. For the test, earth pressure sensors of the type KDE-1MPA or KDE-500KPA are installed in the test soil in order to subsequently measure the stress changes during the production of grout bodies.

The mechanical stresses around the anchor and anchor pull-out are measured at several radial distances from the anchor in all directions and compared with a numerical model. This makes it possible to check whether the theoretical calculations match the real measured values.

These stresses are monitored at various stages: during the insertion of the empty pipe, the filling of cement paste into the empty pipe, the pulling of the casing and the application of pressure to the liquid cement paste.

Image source: Bundesanstalt für Wasserbau (BAW)

After a curing time of one week, the anchor is pulled out of the ground and the stress distribution is monitored again.

A compact sensor geometry and an elastic sensor cable are particularly important for these tests so that the sensors can be arranged and aligned flexibly and precisely in the test container in order to measure stresses at any distance from the anchoring elements. The KDE-1MPA and KDE-500KPA earth pressure sensors from Althen fulfil all the necessary requirements.

About the ground pressure sensors

The miniature soil pressure sensors in the KDE-PA and KDF-PA series are specially designed for modelling tests in the construction industry. With a diameter of just 50 mm, they can be optimally integrated into test set-ups. Their double diaphragm structure minimises the surface displacement of the measuring surface, ensuring precise and interference-free detection of the stress distribution in the soil.

The sensors are made entirely of stainless steel and fulfil protection class IP68, making them suitable for use in extreme conditions. They are available with two cable variants for easy installation - either with a side or centre connection on the rear. Thanks to their robust design, they are a cost-effective and reliable solution for precise earth pressure measurements in research and practical applications.

Soil pressure sensors for field applications

Althen also offers suitable sensors for direct use on construction sites. The KDA-PA/KDB-PA and KDC-PA/KDD-PA ground pressure sensors have an outer diameter of 200 and 100 mm respectively and a double membrane structure. While the KDA-PA is used to measure the pressure in the ground and to monitor the behaviour of slopes, the KDB-PA is suitable for measuring the pressure in embankments or on the walls of buildings. KDC-PA/KDD-PA earth pressure sensors can reliably measure soil pressure in elevated and coastal structures. All sensors can also be used to monitor dynamic earth pressures or waves.

About the measuring chain

For optimum signal amplification, Althen also supplies complete measuring chains that contain both the sensors and suitable measuring amplifiers. These are optimally adapted to the output signals. A measuring chain consisting of the KDE-1MPA and KDE-500KPA earth pressure sensors and an SG-KP 1-channel strain gauge amplifier was used for the tests with the grouted anchoring elements.