In modern glass technology, precise control of melting conditions is of fundamental importance: the viscosity of a melt in particular has a decisive influence on its further processing, quality and homogeneity. In the laboratory, viscosities are often determined using rotational viscometers: a spindle is rotated at a constant speed in the sample, the required torque is measured and the viscous resistance – i.e. the viscosity – is determined from this.

In industrial melting processes, especially in glass melting, this form of measurement is often not directly practicable. Instead, monitoring methods are used that provide real-time data and thus allow immediate process control.

In our customer's current project, this concerns the melting of quartz glass, where viscosity is not only a measure of fluidity, but also allows conclusions to be drawn about the internal state of the melt – for example, cavities (air bubbles) or incomplete material bonding.

Project and objectives

An industrial company focusing on precision glass components planned to improve the manufacturing process for quartz glass in terms of quality and process reliability. In this specific application, the challenge was that the glass is first melted at high temperatures and then has to reach a defined viscosity zone for further processing. Only in this range can it be guaranteed that

- the melt is homogeneous (no air bubbles),

- the connection or fusion of different material batches has taken place completely,

- the transition to the shaping or quenching/pre-forming process starts reliably.

The objective was therefore to reliably monitor the viscosity of the quartz glass melt in order to detect deviations in the melting process at an early stage and to establish process-reliable feedback for control and quality assurance.

Significance of viscosity in quartz glass

The viscosity of molten glass plays a key role in processing, as it determines the flowability and thus the moulding behaviour, bubble removal, degassing and homogenisation. In the case of quartz glass, the conditions are particularly demanding: high temperatures and viscosities, as well as a strong influence of temperature and composition on the viscosity curve.

Typical characteristics:

- As the temperature rises, viscosity decreases significantly, making the material more fluid.

- Small differences in composition or melting state (e.g. particles that have not completely dissolved, air pockets) can have a major impact on viscosity and thus indirectly on quality and processing.

- With quartz glass, precise knowledge of the viscosity-temperature curve is necessary, for example to define ‘working range’ temperatures at which the material can be processed safely.

In the project, viscosity was used as an indicator to monitor the homogeneity of the melt, the presence of undesirable inclusions (e.g. air bubbles) and the complete combination of several material batches.

Solution approach and sensor selection

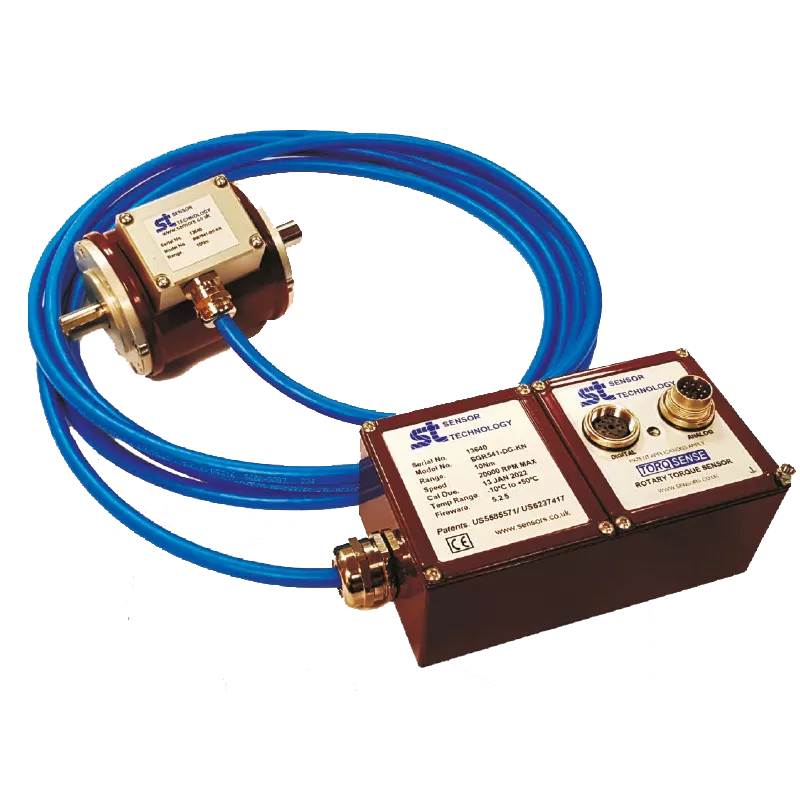

Two torque sensors or measuring systems were considered for viscosity monitoring: the SGR520 and the SGR541. After thorough analysis, the SGR541 was selected and specially adapted for the quartz glass melting application.

Key reasons for choosing the SGR541

- Greater robustness against extreme process conditions (temperatures, thermal shocks, possible vibrations) in the melting range of quartz glass.

- Option for customer-specific adaptation – e.g., reduced measuring shaft, separate sensor unit and electronics via a plug connection.

- Support from Althen regarding documentation, integration into process control, and interfaces for data acquisition and monitoring.

Adaptation to the application

The sensor was mechanically and thermally designed for the melting conditions of quartz glass melt. Calibration was performed using reference samples or model melts in order to map the torque ↔ viscosity relationship in detail in the specific process setup.

The sensor was integrated into the process—typically between the motor/agitator (or melt mixing system) and the impeller (or melt stirrer)—and connected to the process control system in real time. Since torque transducers can be sensitive to lateral forces, the paddle must not be coupled directly to the sensor. Instead, double bearings should be used to avoid transverse forces.

Process implementation

The specific process was divided into several steps:

- Process analysis & target definition

The relevant target values for viscosity were defined together with the customer: e.g., a range from x to y Pa·s at temperature T, at which the melt is considered homogeneous and no bubbles are mobile. - Sensor Installation

The SGR541 was mechanically mounted so that it could reliably measure the torque or torsion in the stirring system. A double bearing mount ensured that transverse forces were minimized. - Calibration and referencing

Reference curves were created using laboratory or pilot melts with known compositions and viscosity values. This allowed the sensor output to be mapped to absolute or relative viscosity (see Basics: “Torque ↔ Viscosity” at constant speed conditions). - Real-time data acquisition & process monitoring

The sensor continuously provided torque data from which the viscosity was derived. Trend analysis enabled early detection of deviations – for example, if the viscosity did not fall within the target range, which could indicate trapped bubbles or incomplete mixing of the material batches. - Measures in case of deviations

As soon as the measured viscosity deviated from the target curve, measures were taken immediately: adjustment of the temperature, extension of the stirring time, addition of degassing (refining), or even return of the batch for reprocessing.

Results and benefits

The introduction of monitoring using SGR541 had the following positive effects:

-

Greater process reliabilityThe melt could be continuously monitored for homogeneity and freedom from bubbles. Deviations were detected early and corrected.

-

Quality assuranceThe typical source of error, “air bubbles in the quartz melt,” was significantly reduced, as their formation was indicated by increased viscosity or deviating viscosity development.

-

Increase in efficiencyLess waste, less rework, fewer stops for manual checks.

-

Scientific feedbackThe data obtained (torque/viscosity curves) provided valuable insights into the behavior of the quartz glass melt, enabling future process optimizations.

Other applications

This method is also used successfully in other applications—e.g., plaster mixtures, coal slurries, and liquids containing magnetic particles—where conventional viscometers fail and viscosity monitoring is required. In industries such as cosmetics and pharmaceuticals—e.g., in the manufacture of shampoos or medical solutions—it is also important to monitor viscosity during mixing. This allows you to determine when the process is complete and the desired consistency has been achieved.

Conclusion

This project impressively demonstrates how the interaction of sensor technology (SGR541), viscosity knowledge, and process integration can lead to significant improvements in quality processes in the field of quartz glass manufacturing. For technical test engineers, process managers, and quality assurance teams, this solution offers a robust basis for increasing efficiency, quality, and safety.