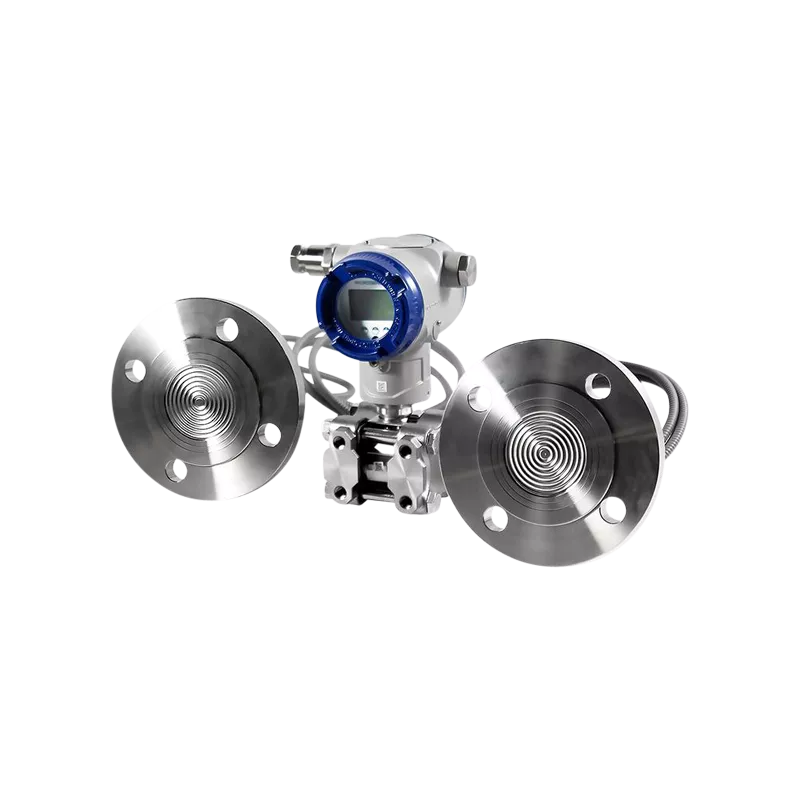

MDM7000-LP Smart differential pressure transmitter with remote diaphragm seals

The MDM7000-LP is a robust smart differential pressure transmitter with remote diaphragm seals, built for precise and stable measurements in demanding process applications. With excellent accuracy, wide configuration flexibility, and global certifications, it’s ideal for harsh, high-temperature, or corrosive environments.

Key features

- Accuracy:±0.2% URL

- Range: 0.4bar~2.5bar

- Long-term stability: ±0.2% Span/10 years

- DNV, ABS, KR, NK, and RS approved for installation on vessels

About the MDM7000-LP Smart differential pressure transmitter

The MDM7000-LP is a high-performance differential pressure transmitter designed for critical industrial applications where remote diaphragm seals are required. These seals allow for accurate pressure measurement in systems with high temperatures, aggressive chemicals, or difficult-to-access pipework, such as tanks, reactors, or distillation columns.

Key features

- Remote diaphragm seal design: ideal for extreme process conditions including high temperature, corrosive media, or long-distance tank installations.

- High accuracy & long-term stability: delivers up to ±0.2% URL accuracy and ±0.2% span stability over 10 years, even under fluctuating conditions.

- Modular, certified, and flexible: supports HART & Bluetooth, multiple flange types and fill fluids, with certifications for global hazardous environments.

Further description

Equipped with monocrystalline silicon sensor technology, the transmitter provides ±0.2% URL accuracy, a 100:1 turndown ratio, and long-term stability of ±0.2% span over 10 years. The modular design supports a wide range of flange standards (EN, ANSI, HG/T), pressure classes (up to PN100/Class 600), and custom capillary lengths up to 10 meters. It’s available with a variety of wetted materials including 316L, Hastelloy C, Tantalum, Titanium, and more for excellent chemical resistance.

The transmitter supports 4–20mA HART communication and offers optional Bluetooth, high-accuracy calibration, and integrated valve manifolds for easy setup and maintenance. Its IP67 housing and intrinsically safe or flameproof certifications (ATEX, IECEx, CSA, NEPSI, EAC, etc.) make it suitable for deployment in hazardous areas across chemical, oil & gas, marine, and power generation industries.

Typical applications

Thanks to its remote diaphragm seal design, wide configurability, and high accuracy, the MDM7000-LP is ideal for:

- Chemical and petrochemical: for level, flow, and pressure measurements in reactors, separators, and corrosive fluid systems

- Oil and gas: accurate monitoring in pipelines, offshore platforms, and process skids—especially in hazardous areas

- Power generation: for pressure drop measurement across filters, turbines, and high-pressure steam systems

- Marine & offshore: approved by CCS, DNV, ABS, etc., ideal for ballast systems and engine room monitoring

- Water & wastewater: monitoring differential pressure across membranes and filters in treatment facilities

- Food & pharmaceutical (when configured accordingly):

For hygienic pressure measurement in CIP/SIP processes with PTFE or gold-plated diaphragms

The MDM7000-LP is suitable for outdoor installations, aggressive media, and areas exposed to mechanical stress or thermal fluctuations.

Do you need this sensor for your next project?

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Talk to our experts

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Accuracy | ±0.2% URL + Diaphragm seal system effffects |

| Range | 0.4bar~2.5bar, see the specififications for details |

| Turn down ratio | 100:1 |

| Long-term stability | ±0.2% Span/10 years |

| Ambient temperature effffects | The total effffect per 10ºC in the range of -20ºC ~80ºC: (0.375+0.125TD)%/10ºC of SPAN |

| Voltage effffects | When the power supply voltage changes within 18.3V~44V DC, its zero point and range change should not exceed ±0.005% URL/V |

| Mounting position effffects | The installation of the transmitter may produce a zero point error, which can be corrected by PV (primary value)=0 reset without any effffect on the range. |

| Vibration effffects | < 0.1% SPAN as per GB/T18271.3/IEC61298-3 |

| Output signal | 4mA~20mA DC, HART |

| IP rating | IP67 |

| Weight | About:6.35kg(body) |

| Operating temperature | Without LCD display: -50℃ ~85℃ ; with LCD display: -40℃ ~70℃ |

| Storage temperature | Without LCD display: -50℃ ~100℃ ; with LCD display: -40℃ ~85℃ |

| Operating humidity | 5%RH~100%RH@40℃ |

Related products

Need something else?

MDM7000LT Smart level transmitter

- Accuracy:±0.2% URL

- Range: 0.4bar~10bar

- Output Signal: 4mA~20mA DC+HART

- DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-DP Smart differential pressure transmitter

- High accuracy and stability (delivers up to ±0.05% URL accuracy with long-term stability of ±0.2% span over 10 years)

- Robust environmental performance. Operates in extreme conditions with IP67 protection, -50°C to +85°C temperature range

- Versatile and certified design. Supports HART and optional Bluetooth communication

MDM7000-GP/AP Smart pressure transmitter

- Accuracy up to 0.075%FS

- Long-term stability: ±0.1% SPAN/5 years

- High voltage overload protection, strong anti-interference ability