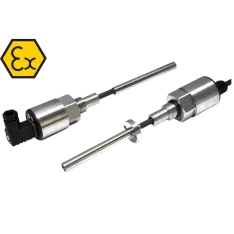

X500 Intrinsically safe rotary sensor

Non-contact inductive rotary sensor for accurate position feedback in hazardous gas or vapor environments. Custom angle range and IP65/67 protection.

Key features

- Intrinsically safe for gas/vapour zones

- Custom angle range from 16° to 160°

- Compact and rugged stainless steel housing

- High resolution and linear output

- IP65 or IP67 sealing options

- Certified ATEX / IECEx / UKEX compliant

Performance highlights

The X500 is a compact rotary sensor engineered for intrinsically safe applications. It features non-contact inductive technology, delivering high accuracy and excellent repeatability across a wide temperature range. With a ratiometric analog output (0.5–4.5V), infinite resolution, and linearity of ≤ ±0.25% FSO, this sensor offers reliable performance even in harsh industrial environments.

Usage conditions

Designed for explosive gas/vapor atmospheres, the X500 complies with Ex II 1G Ex ia IIC T4 Ga (–40°C to +80°C). It is suitable for use with galvanic isolation barriers and supports both 3-wire and 5-wire configurations. Protection levels include IP65 or IP67 depending on connector or cable options. Vibration and shock ratings meet IEC standards for rugged use.

Possible applications

- Valve position feedback in chemical plants

- Rotary actuator feedback in oil & gas zones

- Shaft angle measurement in mining operations

- Position feedback for process automation in hazardous environments

- Robotics and motion systems in ATEX zones

Advantages of choosing this product

The X500 delivers long service life, low torque, and outstanding stability, eliminating mechanical wear due to its non-contact inductive sensing principle. The angle is factory-calibrated to customer requirements, making it ideal for OEM integration. A full range of connectors and mounting options allows easy integration across various applications.

Other important features

- Full 360° shaft rotation

- Low noise: < 0.02% FSO

- Frequency response > 10kHz

- Optional spring-loaded shaft

- EMC compliant to EN 61000-6-2 / -6-3

- MTBF of 350,000 hrs at 40°C

Do you need this sensor for your next project?

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Product downloads

Talk to our experts

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Body diameter | 35mm |

| Body length (to seal face) | 44 mm |

| Shaft size | 6 mm Ø |

| Independent linearity | ≤ ±0.25% FSO @ 20°C (≤100°) |

| Temperature coefficients | < ±0.01%/°C Gain, < ±0.01%FS/°C Offset |

| Frequency response | > 10 kHz (–3dB) |

| Resolution | Infinite |

| Noise | < 0.02% FSO |

| Torque | < 20 mNm |

| Intrinsic safety | Ex II 1G, Ex ia IIC T4 Ga |

| Operating temperature range | –40°C to +80°C |

| Storage temperature range | –40°C to +125°C |

| EMC performance | EN 61000-6-2 / EN 61000-6-3 |

| Sealing | IP65 / IP67 (depending on connector) |

| Vibration | 10 g (IEC 68-2-6) |

| Shock | 40 g (IEC 68-2-29) |

| MTBF | 350,000 hrs at 40°C |

| Output signal | 0.5–4.5V ratiometric (5V input) |

| Load resistance | 5 kΩ min |

Related products

Need something else?

P500 Rotary inductive position sensor

- Factory-set angle range between 16° and 160°

- Rugged stainless steel body with IP65/IP67 protection

- Infinite resolution with non-contact inductive sensing

X100 Intrinsically safe linear position sensor

- Stroke range: 5 mm to 800 mm

- Non-contact inductive technology

- Sealing to IP65/IP67 available

X101 Stand-Alone Linear Position Sensor

- Intrinsically safe for Zone 0 use

- Stroke range from 5 mm to 800 mm

- IP65/IP67 sealed stainless steel housing