In today’s industries, precision and reliability are crucial. From aerospace engines to hydrogen systems, sensors must perform under extreme pressure and temperature. Traditional technologies often fail in these environments. Silicon-on-Sapphire (SoS) pressure sensors set a new standard for accuracy and durability where others cannot compete.

How Silicon-on-Sapphire technology works

SoS combines a thin layer of silicon with a sapphire substrate — one of the hardest materials on earth. This unique fusion merges silicon’s electronic performance with sapphire’s mechanical strength and temperature resistance. The result is a stable, accurate, and long-lasting sensor that can operate in environments exceeding 300°C without signal drift or degradation.

Key technical benefits:

- Superior long-term stability (<0.2% drift)

- No bonding materials that cause aging or hysteresis

- Excellent electrical isolation and minimal signal noise

- Enhanced sensitivity due to precise silicon alignment on sapphire

Advantages of SoS pressure sensors

1. High-temperature resilience

Where standard silicon sensors fail, SoS sensors continue to perform. They maintain accurate readings in environments up to 300°C and higher, making them ideal for turbines, engines, and high-temperature process lines.

2. Outstanding mechanical durability

Sapphire ranks 9 on the Mohs hardness scale, just below diamond. This gives SoS pressure sensors superior resistance to corrosion, wear, and mechanical stress. Perfect for oil & gas, marine, and subsea operations.

3. Precision and stability

Sapphire’s insulating properties minimize signal interference. The result: exceptionally accurate, repeatable pressure readings even under large temperature or pressure variations.

4. Energy-efficient operation

Thanks to the sapphire substrate’s electrical insulation, SoS sensors consume less power. This efficiency makes them suitable for battery-powered or remote monitoring systems.

5. Compact and integrable design

SoS sensors allow for miniaturization and integration of electronics directly onto the chip. This enables lightweight, high-performance designs for aerospace, automotive, and OEM applications.

Choose the right pressure sensor technology

Different sensing technologies offer distinct advantages depending on the environment and performance requirements. The table below compares Silicon-on-Sapphire (SoS) sensors with piezoresistive and strain gauge types, highlighting how SoS technology stands out in durability, temperature range, and measurement stability.

Piezoresistive sensors

Piezoresistive sensors measure pressure using the change in electrical resistance of silicon when it is mechanically strained. Although this technology is common and cost-effective, it is highly sensitive to temperature changes. These fluctuations can cause measurement errors, often requiring additional temperature compensation circuits. This increases power use and limits performance in high-temperature environments. By contrast, Silicon-on-Sapphire (SoS) sensors offer inherent temperature stability, delivering reliable and consistent performance even under extreme thermal conditions.

Strain gauge sensors

Strain gauge sensors detect pressure by measuring the strain in resistive elements. While functional, they typically provide lower sensitivity and slower response times than SoS sensors. Their materials also tend to degrade faster, reducing long-term reliability in harsh or high-temperature environments. In comparison, SoS sensors maintain their accuracy and durability under extreme conditions, making them the preferred choice for demanding industrial and high-pressure applications.

Applications of Silicon-on-Sapphire pressure sensors

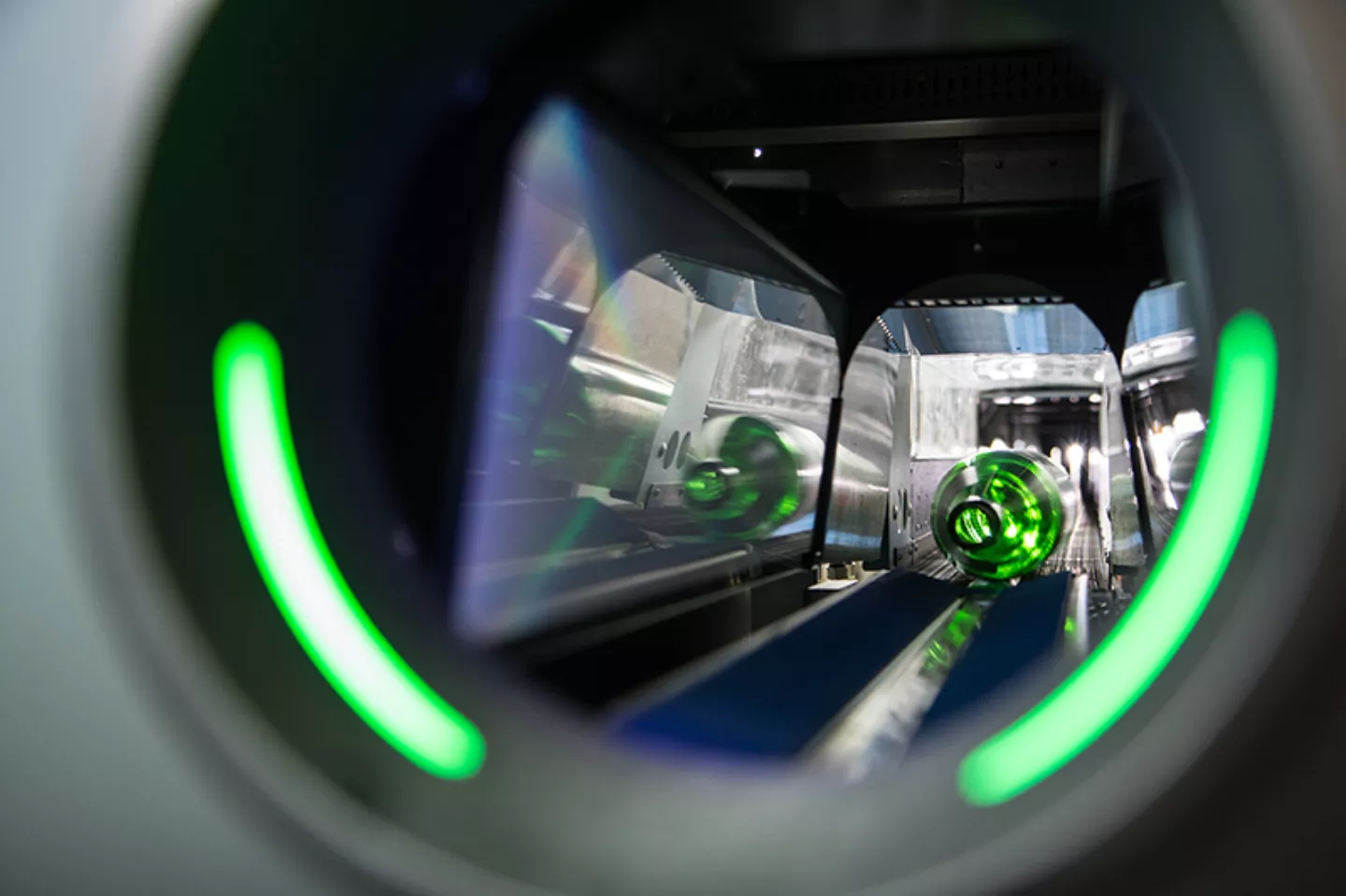

- Aerospace and defense – accurate measurement in jet engines, turbines, and high-altitude systems

- Automotive – precise monitoring for engines and exhaust systems under extreme heat

- Oil & gas – reliable performance in corrosive and high-pressure environments

- Hydrogen systems – long-term stability in high-pressure, chemically reactive conditions

- Industrial automation – accurate process control and monitoring in variable environments

- Marine and offshore – corrosion-resistant pressure sensing for subsea operations

- OEM integration – compact, customizable sensing solutions for system manufacturers

The future of SoS technology

As industries demand more from their measurement systems, Silicon-on-Sapphire continues to lead innovation. Future developments aim to integrate wireless communication, on-chip signal processing, and IoT compatibility, creating even smarter, more connected pressure sensors.

Custom SoS pressure sensors

At Althen Sensors & Controls, we help engineers implement custom SoS pressure sensors tailored to their needs — combining precision, robustness, and long-term reliability.

Examples

Some popular examples of silicon-on-sapphire pressure sensors

AGS4200 Standard Pressure Transducer

- Measuring range: 0 - 0,5 to 0 - 1.500 bar

- Silicon-on-Sapphire sensor technology

- ± 0.25% accuracy, optional ± 0.1%

AHP1000 | AHP1100 High-Pressure Transducer

- Measuring range: 0 - 600 to 0 - 5.000 bar

- High resistance to over-pressure

- RoHS certified

AGS4200H Hydrogen Compatible Pressure Transducer

- Compatible for use within Hydrogen based environment

- Measuring range: 0 - 0,5 to 0 - 1.500 bar

- ± 0.25% accuracy, optional ± 0.1%