ATEX environments place strict demands on every component used in a system. Sensors and joysticks must not only deliver accurate data but also prevent any risk of ignition. This article explores the principles of intrinsic safety, key industrial applications, and Althen’s role in providing certified solutions. Let's start with a brief FAQ covering the most common ATEX-related questions.

Frequently asked questions about ATEX and sensor technology

What does ATEX stand for?

ATEX means ATmosphères EXplosibles and refers to the European directives for equipment used in explosive atmospheres.

When is ATEX certification required?

Whenever there is a potential for explosive gases, vapors, or dust during operation.

What is the difference between ATEX and IECEx?

ATEX is the European certification system; IECEx is international. Devices with both certifications can be used globally.

Which sensors are suitable for ATEX zones?

Sensors that are intrinsically safe or certified for the correct ATEX zone classification (0, 1, 2 / 20, 21, 22).

What does ‘intrinsically safe’ mean?

It means that the electrical energy inside the device is limited so that it cannot ignite an explosive atmosphere, even in fault conditions.

What happens if a device is not ATEX-certified?

Using non-certified equipment in an ATEX zone can lead to explosions and is prohibited by European law.

Why ATEX environments are so demanding

Explosive environments are common in industries such as oil & gas, chemicals, and mining. In these sectors, gases, vapors, or dust particles can ignite when they come into contact with electrical equipment.

To minimize this risk, the European ATEX directives (ATmosphères EXplosibles) define how equipment must be designed and tested to operate safely in explosive zones.

ATEX zone classification:

- Zone 0 / 20: explosive atmosphere present continuously.

- Zone 1 / 21: likely to occur during normal operation.

- Zone 2 / 22: only occurs in abnormal conditions or failures.

In these environments, every sensor and joystick must not only perform accurately but also operate with complete safety.

Intrinsically safe sensors: safety starts with the design

An intrinsically safe sensor is designed so that it cannot release enough electrical or thermal energy to ignite an explosive atmosphere. Even in the event of multiple simultaneous faults. This safety principle is based on energy limitation, not isolation. Instead of enclosing the device in a heavy explosion-proof housing, intrinsic safety focuses on controlling the energy at the source.

How intrinsic safety works technically

Intrinsic safety is achieved by designing the electronics to operate well below ignition energy thresholds.

Inside an intrinsically safe sensor, several protection mechanisms work together:

- Energy limitation: typical limits are around 30 V, 100 mA, and 1.3 W, depending on gas group and zone classification.

- Voltage and current suppression: resistors and Zener diodes prevent power surges and transient spikes.

- Short-circuit protection: fuses or current-limiting resistors ensure no hazardous energy is released under fault conditions.

- Galvanic isolation: prevents high voltage from reaching the sensing circuit.

- Thermal management: all components remain below their rated surface temperature (e.g., T4 ≤ 135 °C).

Together, these design features ensure that even under double-fault conditions, the sensor cannot generate a spark or excessive heat capable of ignition.

While these principles define the internal safety of the sensor, the protection of the entire measurement loop depends on proper system design — including the use of safety barriers and isolation devices.

System design and barriers

In practice, intrinsic safety extends beyond the sensor. The entire circuit — including wiring, connectors, and interface electronics — must be designed to prevent ignition risks. This is achieved through the use of safety barriers and careful control of the system’s electrical parameters.

Zener barriers and galvanic isolators

Two main technologies are used to protect intrinsically safe loops:

- Zener barriers: Use Zener diodes, resistors, and fuses to clamp voltage and limit current. They are cost-effective and reliable but require a solid earth ground. Suitable for compact installations with short cable runs.

- Galvanic isolators: Use transformers or optocouplers to fully separate the safe and hazardous areas. They don’t rely on grounding and maintain signal integrity — ideal for larger or distributed systems.

Both methods ensure that any electrical fault on the safe side cannot transmit enough energy into the hazardous zone to cause ignition.

Cable parameters and system certification

Cable properties also play a role. The capacitance and inductance of long cable runs can store electrical energy that might exceed safe limits. That’s why ATEX and IECEx certifications specify maximum allowed cable capacitance (C) and inductance (L) for each sensor type.

For a loop to be fully certified, both the sensor and the barrier must be tested together and approved under the entity or loop concept. Engineers verify compliance by checking manufacturer documentation and calculating safety margins according to IEC 60079-14.

Design best practices

- Keep intrinsically safe cables separate from power lines.

- Minimize cable length and use shielded cables where possible.

- Verify compatibility between sensor, barrier, and control system.

- Maintain proper documentation and loop drawings for audits.

By following these principles, engineers ensure that the entire measurement chain, from sensor to controller, remains compliant and safe.

The advantages of intrinsically safe sensors

Choosing intrinsically safe sensors offers multiple benefits that extend beyond regulatory compliance. They simplify design, improve reliability, and reduce overall system costs.

1. Maximum safety

Certified for use in Zone 0, 1, and 2, intrinsically safe sensors guarantee that even a double fault won’t release enough energy to ignite an explosive atmosphere. They are trusted in continuous-operation environments such as refineries, gas plants, and underground facilities.

2. Simplified installation and certification

Because the safety mechanism is electrical rather than mechanical, there’s no need for heavy explosion-proof housings or pressure-sealed enclosures.

This allows for lighter, faster installations and easier maintenance access — especially in retrofit projects.

3. Enhanced reliability and reduced maintenance

Low-voltage, low-current operation minimizes component wear and heat buildup, extending sensor lifetime.

The result is stable measurement performance and reduced downtime — critical for process industries operating around the clock.

4. Flexible integration

Intrinsically safe sensors work seamlessly with standard control equipment through approved barriers or isolators.

They can be integrated into PLC systems, transmitters, or DAQ setups with minimal adaptation — offering full compatibility for both new designs and upgrades.

5. Global compliance

Many intrinsically safe sensors carry multiple approvals (ATEX, IECEx, FM, CSA), allowing global deployment across facilities.

For international manufacturers or operators, this reduces complexity and ensures consistent safety standards worldwide.

Summary:

Intrinsically safe sensors provide the perfect balance between safety, simplicity, and long-term performance — making them a smart choice for engineers designing in hazardous environments.

Practical applications

Intrinsically safe sensors are used wherever ignition risks exist and precision is critical:

- Oil & gas: position, level, and pressure monitoring on drilling platforms and pipelines.

- Chemical industry: valve position and flow control under flammable gas conditions.

- Food and pharmaceuticals: silo level monitoring where dust can form explosive mixtures.

- Mining: machine position sensing and control in confined, gas-rich areas.

Examples

Some ATEX products from Althen’s range

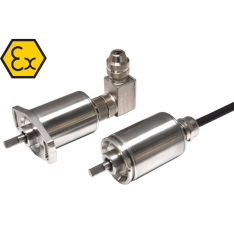

M500 Intrinsically safe rotary sensor

- ATEX / IECEx / UKEX certified for gas, dust and mining

- Non-contact inductive technology eliminates wear

- Suitable for long cable runs up to 1000 m with five-wire mode

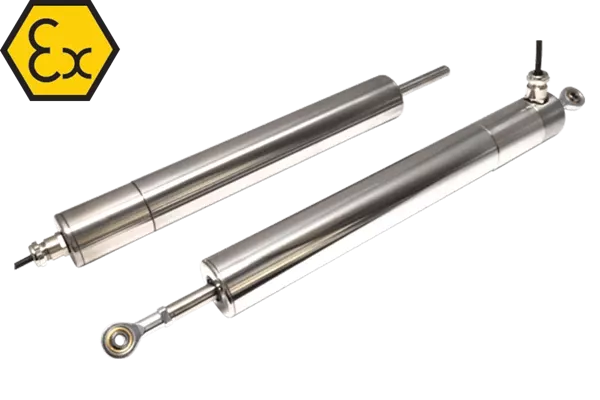

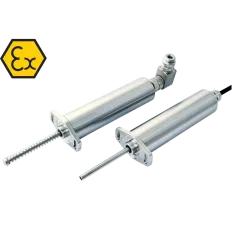

H133 Intrinsically safe mid stroke linear position sensor

- Certified for explosive gas and dust zones

- Tailored travel from 51 mm to 100 mm

- IP67 rugged stainless-steel design

M117 Slim-line linear position sensor

- Certified intrinsically safe for Ex I/II M1/GD zones

- Slim 19 mm housing with flexible mounting options

- Configurable measurement range from 5 to 350 mm

Can we help you?

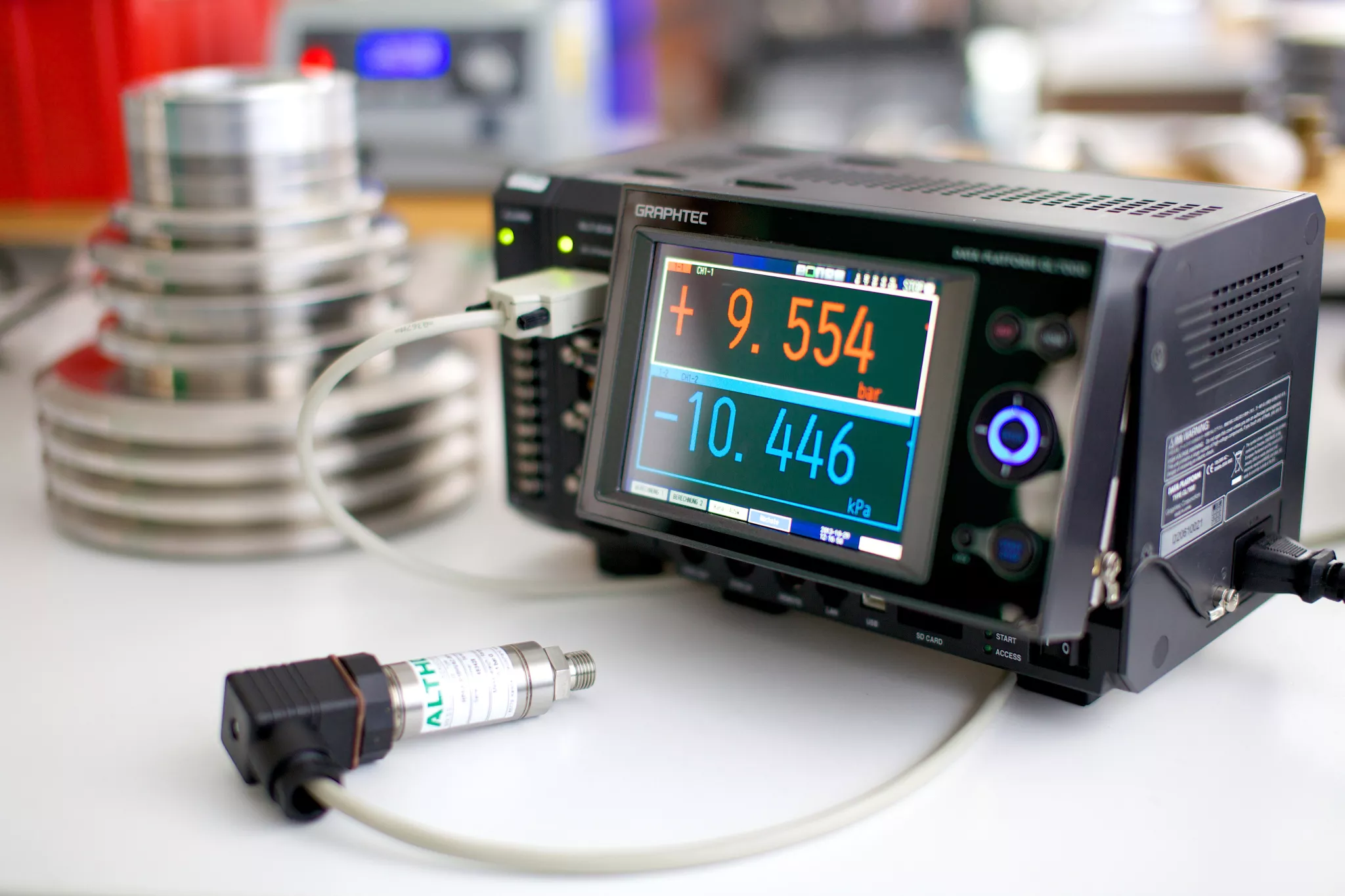

We help customers:

- Select the correct sensor for their ATEX zone.

- Configure barriers and isolators for certified loop design.

- Verify compliance with international standards like EN 60079.

- Integrate intrinsically safe devices into PLC or automation systems.

With decades of experience, we offer not only products but also engineering support, custom solutions, and technical documentation for safe and reliable measurement systems.

Please contact us for technical advice or request a quote.