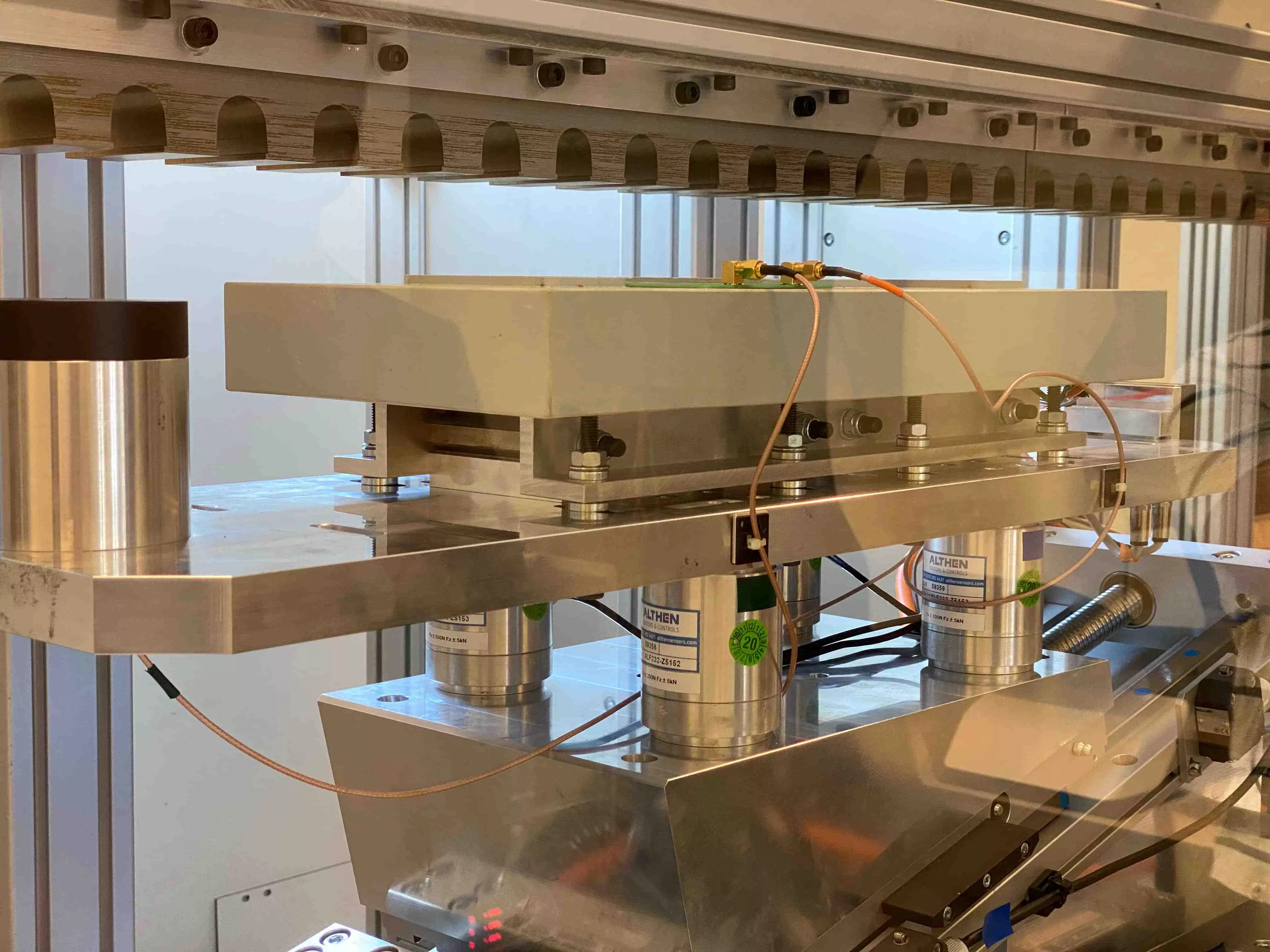

Multi-axis loadcells testing levitation system

For Hardt we supplied multi-axis force sensors. These are ideally suited for many industrial applications. The force transducers are manufactured with force ranges appropriate for the Hyperloop. The multi-axis Force Sensor measures forces in two axes at 90° with measurement ranges from ±100 N to ±5 kN. Apart from error evaluations, each output is pure and requires no mathematical manipulation. The sensors are used to measure the variation in force that is created by the magnetic fields that can be adjusted between the track and the ‘vehicle’.

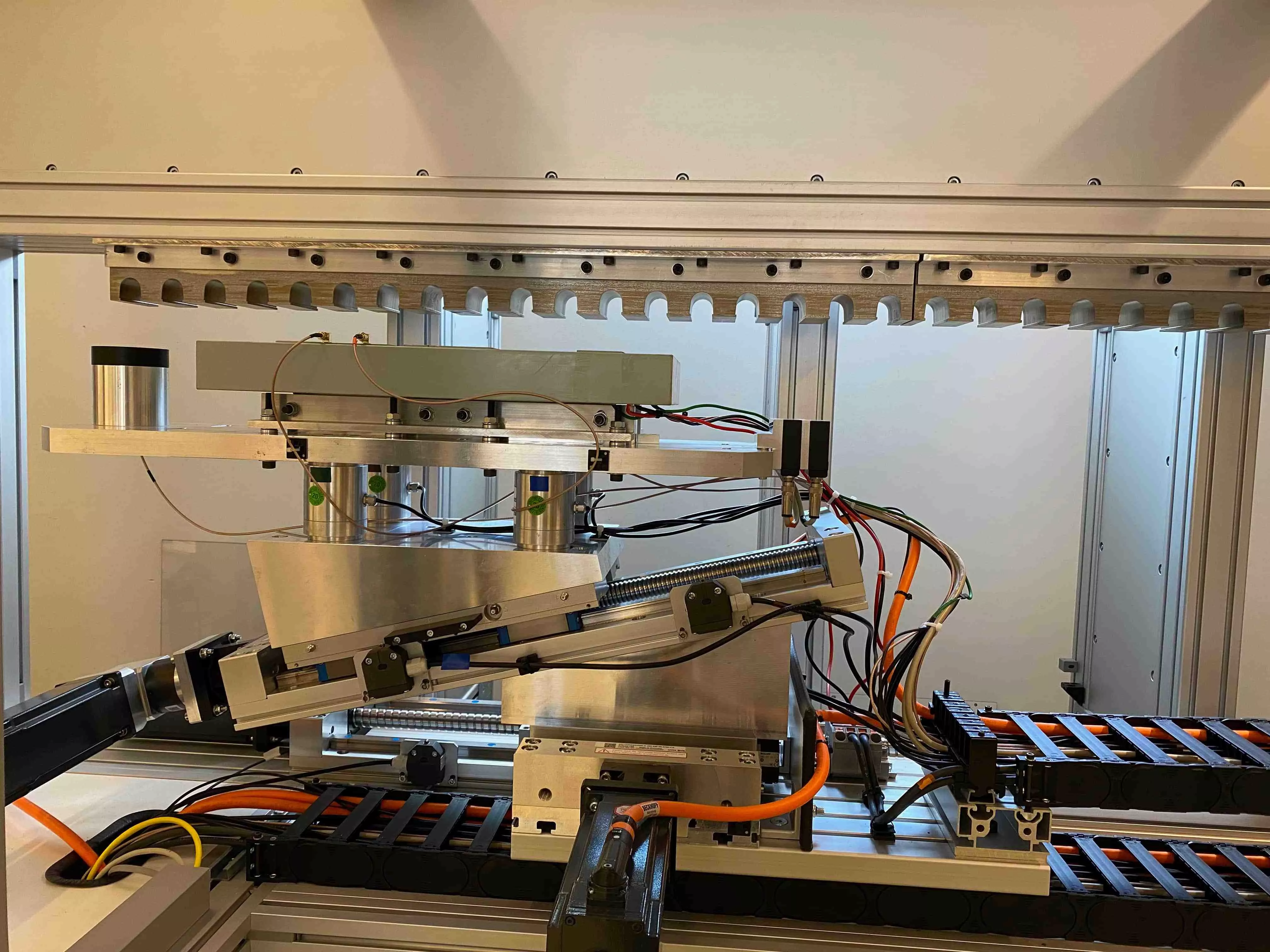

Althen single point laser sensors measure distance to magnetic track

We also supplied Hardt with laser sensors. The single point laser sensors can be used for non-contact measurement of various objects. In general the sensors are suitable to measure displacement, speed, deformation and profiles in static and dynamic applications. The measurement ranges vary from 2 mm up to 1.250 mm. Due to the noncontact measurement, you can avoid force on the target and wear of both target and sensor surfaces. Because the laser spot does not have mass, it follows the target at the same speed. Aside from the measurement of the vehicles position relatively to the maglev track, the laser sensors have also been implemented to measure the lateral position of the chassis and to tune the suspension. Since the frequency of measurement is quite important given the future speed of the vehicle, we have worked with the high-speed version of the RF603 laser sensors.

Hardt Hyperloop and Althen Sensors

In 2017, the Delft Hyperloop team (TU Delft, The Netherlands) won the first SpaceX Hyperloop pod competition. It was after this success that a few students of that winning team started their own Hyperloop company, Hardt. It is one of the first hyperloop companies in the world. In 2017, Althen was the sensor sponsor of this team. We helped design various sensors into the Hyperloop projects every academic year. From high speed laser sensors to draw wire sensors and acceleration sensors - with the main focus on measuring the position of the hyperloop vehicle. We have been closely involved in developing sensor solutions for Hardt ever since.

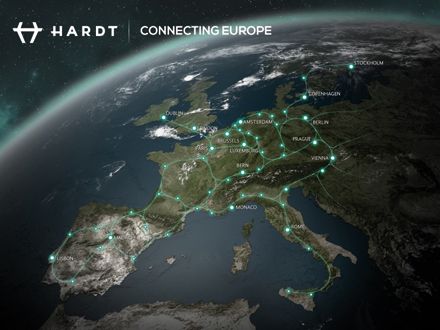

Hardt Hyperloop is on a mission

In 2018 Hardt opened the first European Hyperloop test facility in Delft. In this test facility Hardt tested and developed new solutions for improving the technology of the pod. Since 2019 the company has worked on realizing a high speed test facility that will be used to develop standardized technology for hyperloop tracks all over the Hardt Hyperloop focuses on high quality results and constantly strives for the best. The company is always looking for improvement, learning along the way and coming up with smart solutions. It is the ambition of Hardt Hyperloop to realize a hyperloop network of 100,000 kilometers by 2050. Each new route added to the network will bring further synergies and overlapping benefits. Ultimately, a global hyperloop network will span the continents, providing fast and sustainable connections to major economic and population centers.

Related products

ALF310 Multi-axis Force Sensor

- Measuring range range: 50N / 2Nm

- Axial force and torque transducer

- Minimal cross talk & user friendly outputs

FDRF603 Series Laser Triangulation Sensor

- Measuring ranges: from 2 mm to 1.250 mm

- Universal for many applications

- 0,02% of the range/°С temperature drift

FDMK30 Series Draw-Wire Sensors (String Pot)

- Measuring range: 50 mm to 750 mm

- Smallest design in its class

- Low-cost model