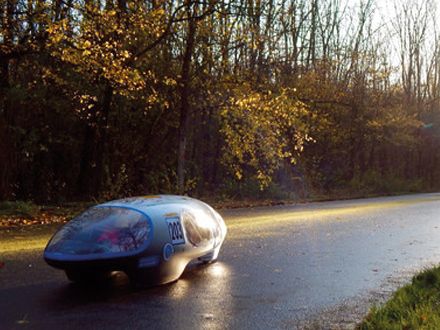

One of the ways the team validates their designs is a dynamometer. A dynamometer has various utilities. One of which is that the team can test any track, at any moment. This is a great optimizing tool to use, as the students normally can only test each component individually, it is now possible to test the whole system at once, and that is the most important test. In that way they know for sure what the limits of the powertrain are, as well as further convolute the best strategy during the race.

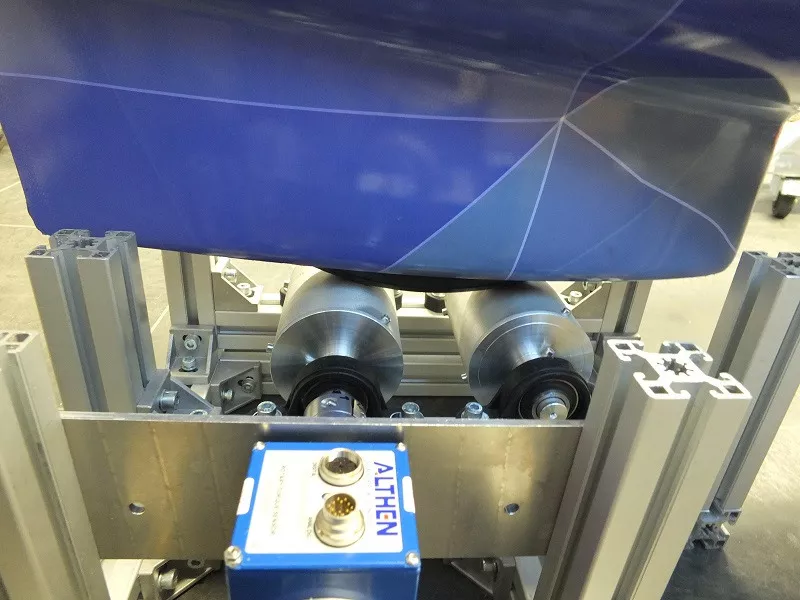

High stress tests for emergency stops can be simulated, or the efficiency of the regenerative braking. The data is live represented and logged for later analysis. That can later be used for perfect tuning of the motor controller for example, and various subsystems.

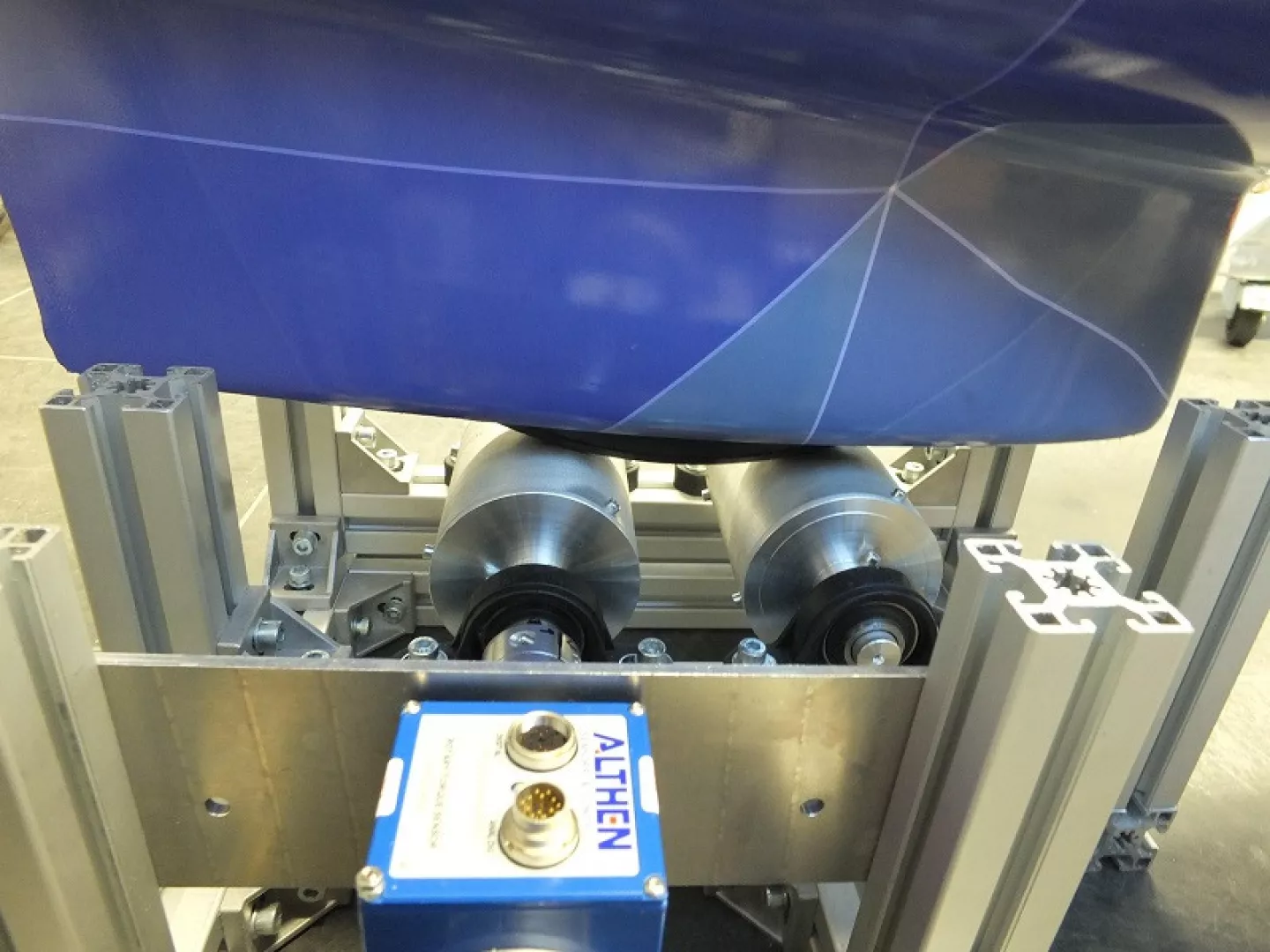

Rotating Torque Sensor with high reliability and accuracy

The Eco-Runner has such a high fuel efficiency that they cannot use a regular Dynamometer. So they created their own, with as key component the RWT410 | RWT420 Rotating Torque Sensor of our partner Sensor Technology, allows them to test the complete powertrain with high reliability and accuracy. With the Rotating Torque Transducer they can send the data to the computer for a better representation of the data and for storage.

The engineers of Althen provided them with the necessary stand-alone support software for their transducers in LabVIEW. This allowed them to make a custom and modular testing system with easy implementations of the sensor.

Predicted efficiency & Real data

The dynamometer will be used to simulate stress points that may occur during the race and evaluate if everything is up to spec. Another more important function that they will add will be to simulate the whole track for the whole powertrain. This is key to not only optimize the powertrain as a whole, but also refine the strategy simulations. For that, the team is trying to expand the capabilities of the dynamometer via software, like adding a regenerative braking simulation.

When the race track is known, they can simulate it, and validate their models extensively. They can even run tests on hydrogen, to see whether the predicted efficiency meets up with the real data. And all that in their own workshop, where it is dry and clean, and where we can safely measure everything we want to know about the car as a whole and the powertrain in particular.

In summary, the dynamometer with the RWT 410/420 Torque Transducer is crucial in the design and testing phase for the powertrain and strategy department.

Accept the marketing cookies to view this video.

Click here to change your consent.