Control system data input

Most modern chillers and cooling systems are controlled by a process control system such as a PLC (Programmable Logic Controller) or a similar interface. PLC's can easily accept 4-20 mA analogue inputs and other common process signals. Factories using a PLC for control often take advantage of this opportunity to realise the cost savings of online vibration monitoring by sending 4-20 mA analogue vibration data directly to their PLC.

Two methods for a 4-20 mA vibration signal

Standard accelerometers provide dynamic vibration data that is too complex to feed into a PLC. However, there are two methods to make a 4-20 mA vibration signal available to the PLC system. Traditional dynamic IEPE (Integrated Electronic Piezoelectric) accelerometers can be wired through a signal conditioning module to create a 4-20 mA output. Another option is accelerometers with the signal conditioner inside that directly output the required 4-20 mA signal from the sensors. Such as the PCC420 series of loop powered sensors from Wilcoxon.

High voltage accelerometers

Most accelerometers are suitable for hot and humid industrial environments, but can fail when exposed to high transient voltages. High voltage accelerometers (HV) are insensitive to electrically noisy environments due to extraordinary EMI and EFT protection and high electrical isolation between the sensor circuits and the machine.

Monitoring fans running above / below 300 RPM

Small cooling cells and many HVAC cooling system fans will have fan speeds over 300 RPM. Where fan speeds exceed 300 RPM, the PCC420 series works well. Dynamic vibration data is converted to a 4-20 mA signal within the sensor housing and output directly to a PLC, with no need for additional monitoring units. Fan speeds above 300 RPM are best monitored with Wilcoxon models PCC420VR-10-R6 or PCC420VP-10-R6.

Large cells, towers and coolers will have slower speeds, typically below 300 RPM. At slower speeds, the vibration signal becomes very small. The small signals from slower rotating speeds require special consideration to accurately detect imbalance and looseness.

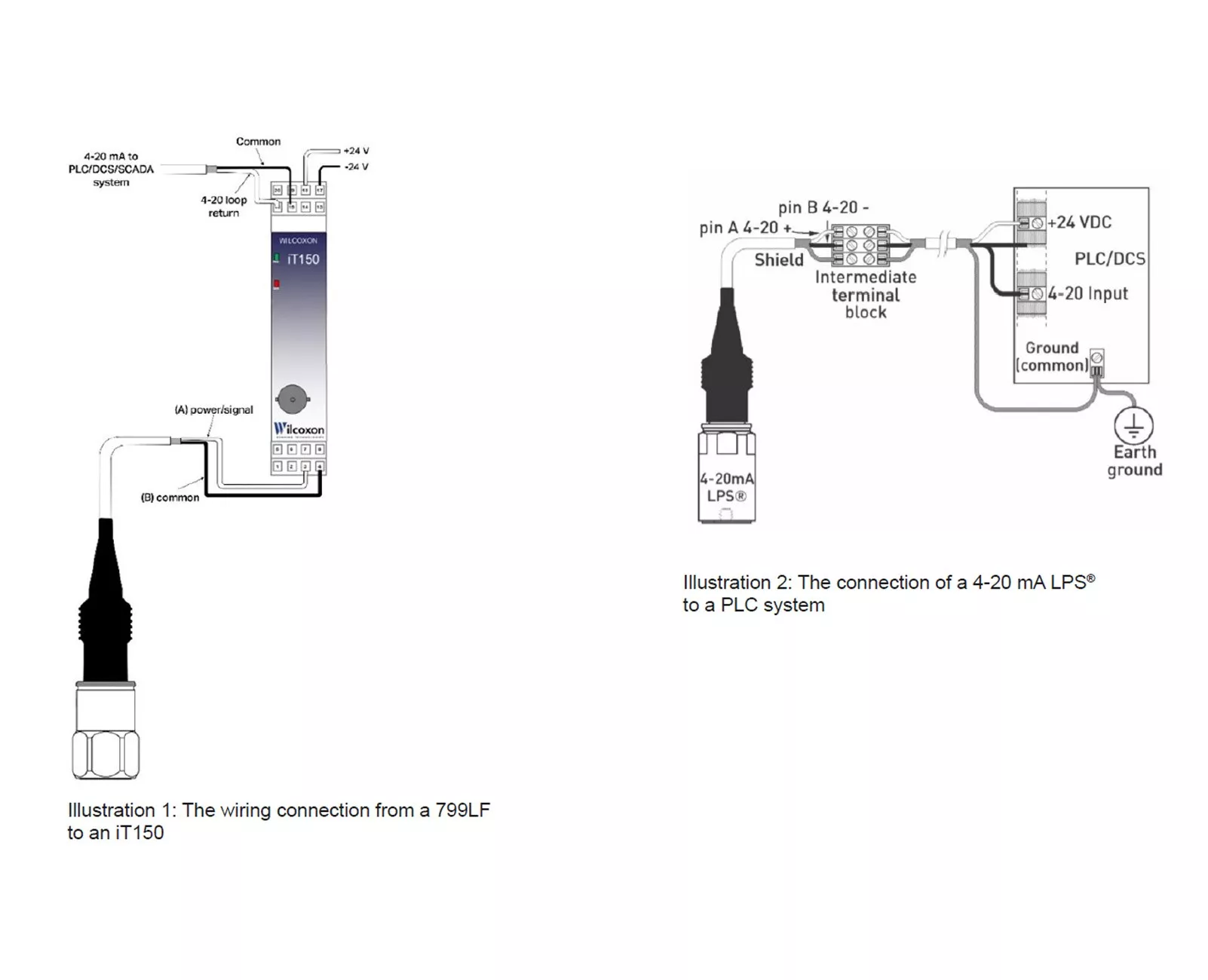

Wilcoxon’s 799LF and 786LF-500 low-frequency accelerometers are excellent for low-speed monitoring. However, they are IEPE accelerometers and do not directly produce a 4-20 mA signal. The Wilcoxon iT150, iT300 or iT301 vibration transmitters, when used with an IEPE accelerometer, will produce a 4-20 mA signal for use by the process control system. In addition, the raw vibration data is still available for further vibration analysis. The combined 799LF and iT150, shown in Illustration 1, can monitor fans at speeds as slow as 60 RPM with accurate results.

Sensor locations

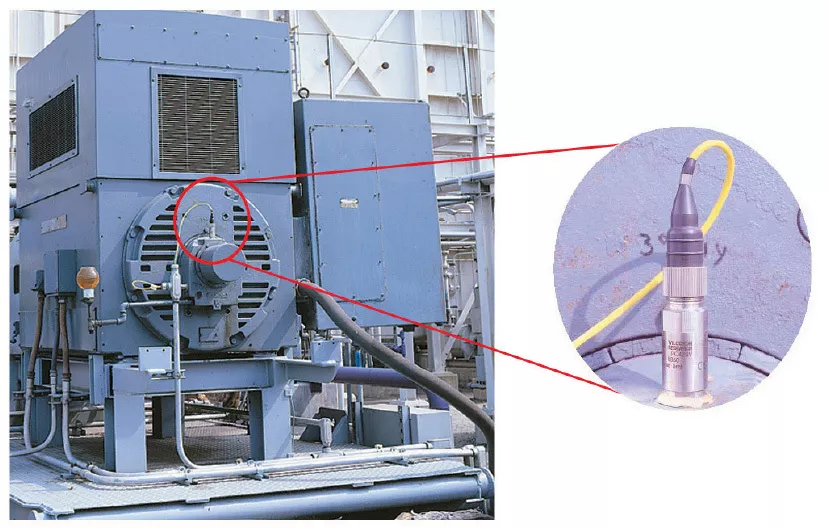

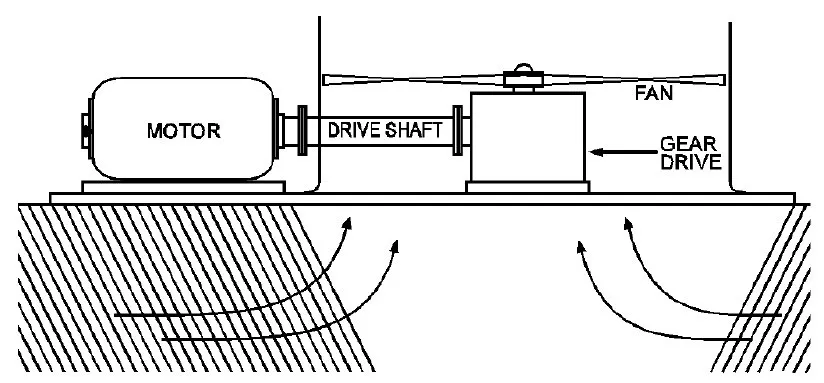

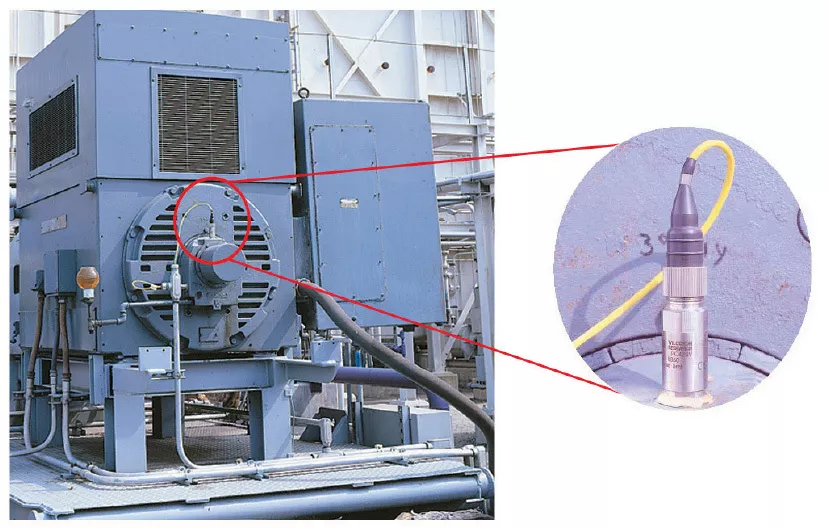

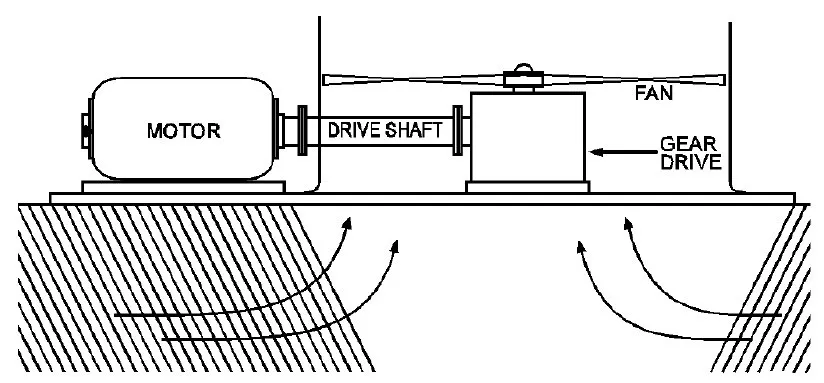

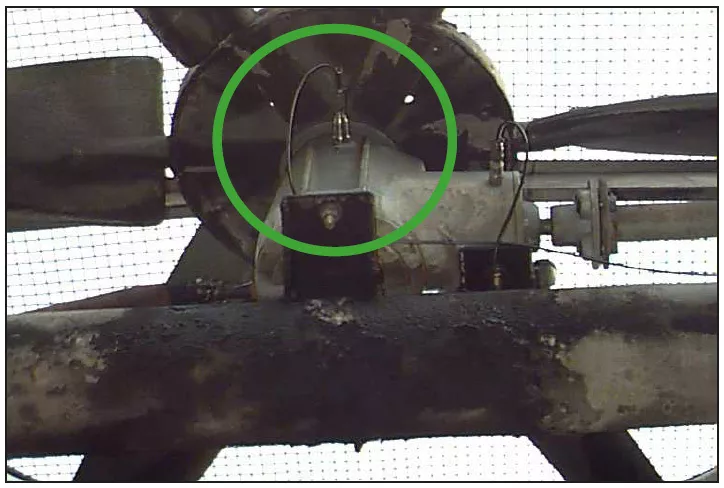

A primary concern in cooling units is the integrity of the fan assembly. A failure of the fan assembly usually results in serious damage to the structure and potential damage to nearby structures or injury of personnel in the area around the cooling unit. Whether a 4-20 mA sensor or an IEPE accelerometer plus vibration transmitter is used, it is recommended to mount the sensor on the side of the gearbox, as shown in the picture. This will allow the sensor to monitor the fan assembly for the onset of imbalance, as well as detection of developing looseness in the gearbox or supporting structure.

Connectors and cables

The wet or outdoor nature of chiller and cooling system installations requires that only the best cable and connectors should be used. The Wilcoxon 6Q boot connector has been tested for underwater installations and is the best connector to use for cooling towers, coolers, and HVAC system installations. The shield connection at the sensor will usually be isolated while the shield will connect at the PLC end of the cable.

The best cable to use is a Teflon® jacketed, shielded, twisted pair cable because of its durability and protection. Wilcoxon’s J9T2A cable has superior chemical and ultraviolet resistance, making it ideal for outdoor and wet environments, as well as shielding to protect the vibration signal.

Wiring overview

Illustrated below are the basic wiring connections for either type of sensor installation. Illustration 1 shows the 799LF connected to the iT150 vibration transmitter. Illustrated here are the input, power, and output wiring connections. The 4-20 mA output of the iT150 unit will wire directly to the PLC system input. The J9T2A cable can be used for the connection from the 799LF to the iT150. Illustration 2 shows how the PCC420V series or other similar 4-20mA sensor is wired directly to the PLC system.

Summary

Cooling towers, process coolers and HVAC cooling units can be monitored for changes in vibration using the 4-20 mA analog input channels of existing PLC units. Fans running below 300 RPM are best monitored using a low-frequency accelerometer and a Wilcoxon iT Transmitter. This combination provides the best sensitivity and frequency response for slow-speed machines. Fan units running at speeds above 300 RPM can be easily monitored using 4-20 mA vibration sensors. Wilcoxon’s PCC420VR-10-R6 and PCC420VP-10-R6 are ideal for this application.

Related products

PCC420A Series 4-20 mA Vibration Sensors

- Continuous trend display of machine vibration

- True RMS or calculated peak output

- Easily integrated into existing process control systems

PCC420V Series 4-20 mA Vibration Sensors

- Continuous trend display of machine vibration

- Peak or RMS detection

- Compact housing for applications with height restrictions

PC420A Series 4-20 mA Vibration Sensors

- True RMS or calculated peak output

- Easily integrated into existing process control systems

- Corrosion resistant