How the wireless wheel load system works

After placing all 16 sensors (we call these Load Cells) on the track right under the lifted vehicle, the maintenance engineer can zero (Tare) all sensors at once before actually lowering the vehicle onto the load cells. In order to give maximum accuracy we have designed these sensors with multiple sensing elements to reach a stunning 0,1% Full Scale Accuracy. The results are shown in both numerical-view and visual view, taking your specific tolerances and calculations into consideration. Finally a report will be generated and automatically saved making sure no data is lost.

Applications

- Tram or metro maintenance, weighing and balancing

Features of Wireless Wheel Load Measurement System

- Simple (easy to handle by operator)

- Wireless communication (no cables)

- Smart software (integrated calculations and reporting)

- Robust system design

- Fully covered service (inspection, configuration, calibration, repair, SLA)

The shown set is developed for HTM – The Hague: an innovative, safe, reliable and comfortable transportation company. With special thanks to HTM, for their input & commitment! In this example: Alstom Citadis & Siemens Avenio. In the maintenance workshop of HTM.

Download specifications

Feel free to download the datasheet of this product here

Heavy duty measurement system

Because of the industrial environment of railway maintenance locations (vehicle, workshop, tools and lifting equipment all consist of heavy duty metals) we have equipped each sensor with a transmitter capable of reaching 800m in free line of site. Integrated electronics take care of both amplification of the signal as well as transmitting the data to the receiver, this way the software is able to acquire all 16 sensor-signals simultaneously. The sensing elements are actually quite passive and don’t need much power, because of this you can use the system for almost 30 days before recharging. Showing the live results of every single wheel the software calculates axle loads and the difference in balance for every single axle.

Easily measure load and balance of each axle

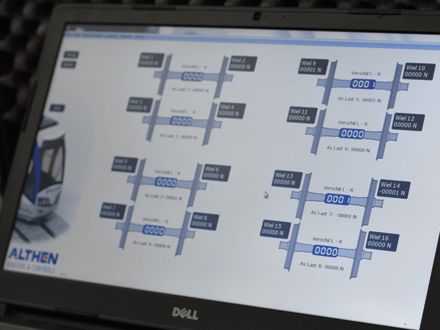

The visual representation of the 4 bogies in the dashboard gives the maintenance engineer all needed data about load on each bogie and at the same time an easy visual representation and overview of the balance for each axle. In addition the software calculates and shows the average axle loads for each axle individually as well as the total weight of the complete vehicle. After adjustments have been made the maintenance engineer can create a report at one click by entering the vehicle number and his name. An automated report will be quickly generated and saved at the same time.

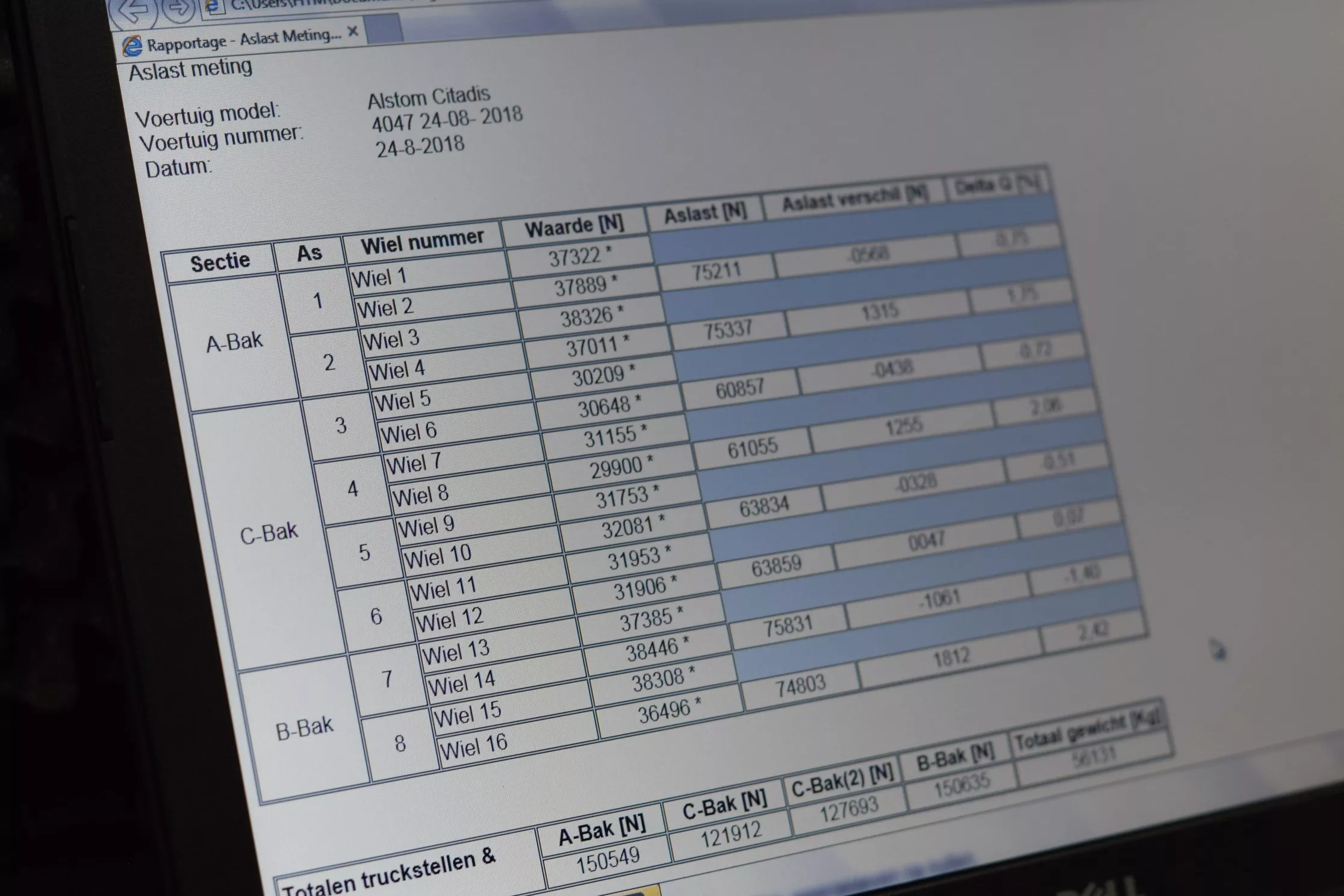

Automated report with calculated key-data

The automated report generated by the software includes all measured data and relevant calculated key-data necessary to meet maintenance requirements. Upon request the software can be custom designed and modified. Because most transportation companies own various makes and models of vehicles the software is designed to meet multiple configuration, calculation and tolerance settings. This way the operator can first choose which vehicle he is measuring or weighing and the software adapts its calculations and tolerances accordingly.

Accept the marketing cookies to view this video.

Click here to change your consent.