FDRF096-Insp Laser Debris Inspection System

For non-contact detection of the debris inside the circular grooves of different items

About the FDRF096-Insp Laser Debris Inspection System

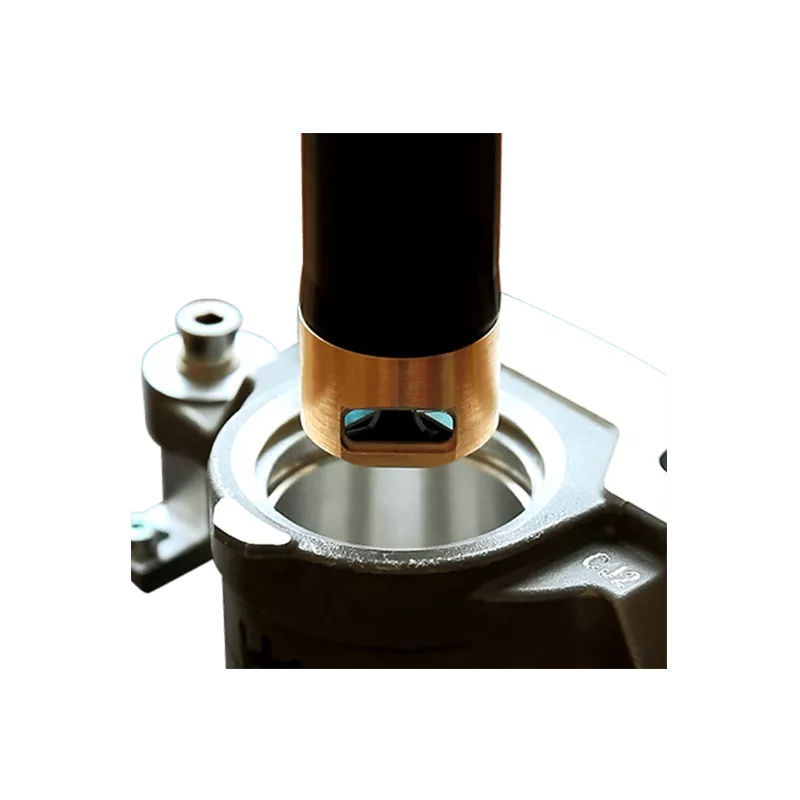

This system is intended for non-contact dection of the debris inside the circular grooves of different technological items such as brake calipers and so on. The system can be used also for groove seal profiling (seal deformation inspection).

The operation of the system is based on the scanning of the item surface by a binocular triangulation laser sensor. It contains a laser sensor mounted on a rotating module. Radiation of a semiconductor laser from the sensor is focused onto the item surface. Radiation reflected by the surface is collected by laser sensor and corresponding angle of rotation from polar coordinates of the surface. An in-built signal processor analyzes the surface profile and detects the presence of debris on the surface.

Do you need this sensor for your next project?

Request a quotation today or leave your details to recieve more information from one of our experts.

Have it your way

Not exactly what you’re looking for? We offer standard sensors but can also help you with a tailor-made sensor or a complete measuring solution. Please contact us for advice or budgetary pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Housing material | Aluminum |

| Inspected grooves diameter range | 35-53mm |

| Inspection time | 1,2s |

| Ip rating | IP67 |

| Laser sensor linearity | ±10µm |

| Light source | Red semiconductor laser, 660nm wavelength |

| Minimal size of detected debris | 0,03 (thickness) x 0,1 x 0,1 |

| Space resolution (points/turnover) | 3200 |