02 August 2022

For HTM Althen installed 3D Wheel+ measuring system at the Central Station in The Hague. This is an advanced measuring system for detection of trains or trams, detection of wheel rims, and weighing these vehicles in motion. During specific times the installation could only take place during the night. The entire system was installed, configured, calibrated and tested by us and our partners.

HTM wants to map all (operating) vehicles with automatic wheel measurements. Wheel measurements are needed for both normal maintenance work and an innovative vision on predictive maintenance. The wheel measurement system installed by Althen in the nights can take all measurements automatically on passing vehicles without them stopping and without this having any impact on the timetable. The wear profile and safety values can thus be permanently monitored.

Althen's 3D Wheel+ measuring system for trains and trams

The system consists of RFiD antennas, laser sensors to measure the various wheel parameters and a dynamic weighing/impact system to map the various loads and wheel defects. In short, the Custom Weighing in Motion (AWIM) measurement system measures all aspects of the flange and wheel. Wear characteristics, dimensions, weight aspects (per vehicle, axle and wheel), and wheel defects. Althen also takes care of the backend and the dashboard.

Relevant data for the HTM Data Hub

The goal is to feed the newly established HTM Data Hub with relevant data and also to generate alerts in case of certain threshold violations so that the right department is informed about the situation per vehicle. The system that Althen supplies and installs for HTM takes care of the measurement of the wheel parameters, the identification of the vehicles and the detection of wheel defects.

System integrator for hardware and software

As a system integrator, Althen Sensors & Controls takes care of the integration of the various systems for both hard- and software. The data streams are organised, linked and analysed by Althen. It is therefore our responsibility to combine the various data streams into a clear one-way communication to feed the HTM Data Hub. HTM wants to receive all agreed parameters in a clear and simple data communication.

Components of the 3D Wheel+ installation

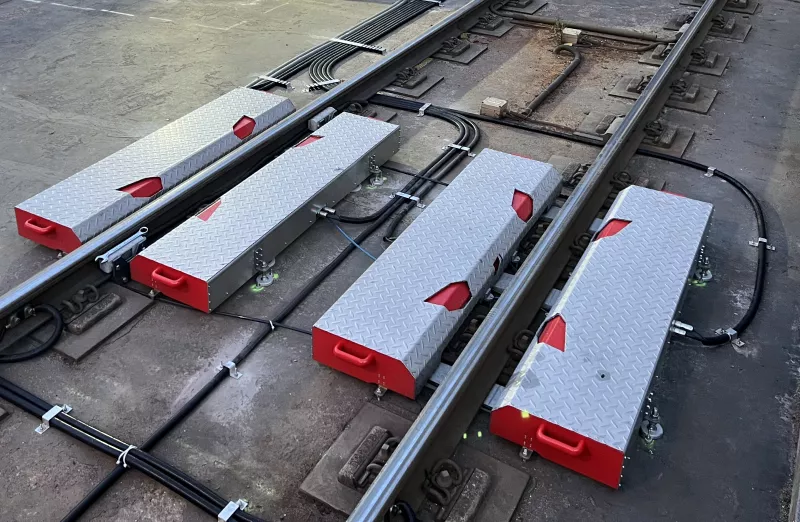

During the installation of Althen, the following components were installed:

- 32 force sensors belonging to the AWIM. These force sensors can also measure vibrations and deformations in rails. The sensors are bolted to the track;

- Cabinet with electronics, processing unit and communication equipment of the AWIM system;

- Cabling between the various sensors and cabinets;

- Installation of radio-frequency identification antennas, taking into account the speed of the vehicles;

- Vehicle detection sensors. This enables the system to detect when a vehicle is driving on the track and approaches the measuring system;

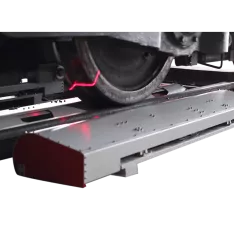

- Laser sensors (automatic laser scanner measuring system 3D Wheel). These are essentially 4 elongated horizontal housings, each of which is equipped with 5 laser scanners, among other things. Each set of 2 is placed on either side of the rail. This system is also equipped with heating, cooling, compressed air and air conditioning. This allows the entire system to be kept clean and functioning properly throughout the entire year;

- Cabinet boxes for the 3D Wheel system. These are 3 systems on location. A cabinet for the power control, the electronics, the processing units, communication, air conditioning, compressed air and compressed air tank.

Notifications at threshold values and tolerances

It is also important that specific departments within HTM receive an e-mail notification when certain measurement results fall outside threshold values. These threshold values or tolerances vary per tram model. It is therefore important that Althen identifies each tram and combines the corresponding measurements from 3 systems, analyses them and takes action based on configurable threshold values.

What are the next steps?

After our installation, the system is not yet ready for use. Both the laser measurement system and the dynamic weighing system will have to be further configured remotely. Even after the complete calibration process, both systems need a few days to "learn". Some parameters such as wheel-defect detection are being refined by AI. In the end, Althen will of course teach HTM employees how to use the system and provide the necessary training.

Althen measurement systems for railways

We are extremely proud how our team, together with HTM and our partners, has realised this 3D Wheel+ measuring system so far. Our measuring systems for railways and tramways are based on laser measuring technology and measure both rails and wheels. Within seconds, the railway measurement systems perform all kinds of highly accurate measurements. In the past, this kind of measurement took a lot of time and effort. In addition, trains, trams, metro and track will be out of service for a shorter period of time, and repair time and related costs can be handled much more efficiently.

Do you have any questions about the 3D Wheel+ measuring system for railway applications? Can we help you with other measuring systems or sensor solutions? We will be glad to help you.

Weighing in Motion (AWIM)

- Train direction and speed

- Identifiation number, Locomotive- & Wagontype

- Very high accurate load measurements (< ±0,5%)

- Weight of single wheel, axles, bogies and complete wagons

- Number of axles

- Very high accurate uneven load detection

- Overload detection

- Wheel Flat Detection (defects)

- Detection system for Derailment Risk

3D Wheel Measurement System

- Accurate and valuable data within seconds

- Eliminate manual measurement errors

- Integrated software system with all necessary calculations and parameters