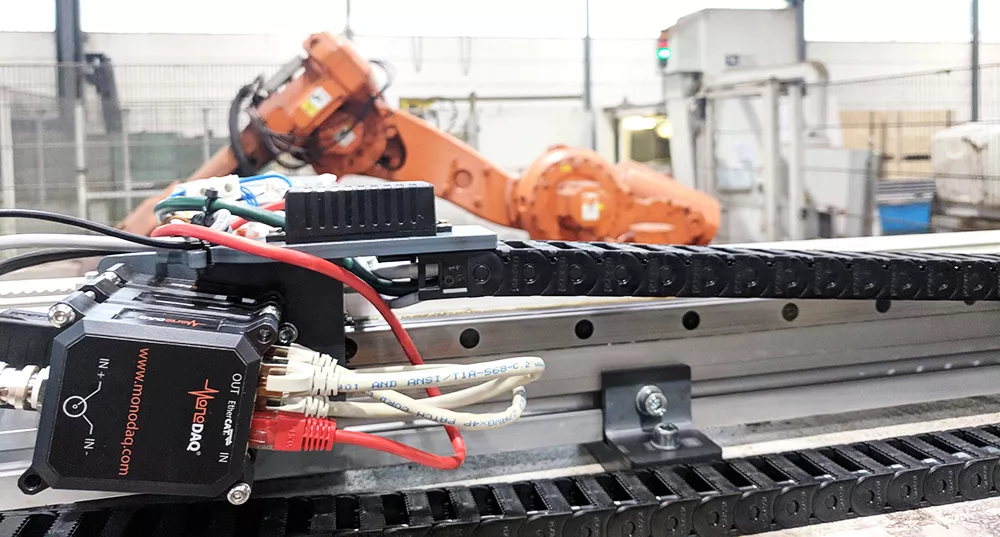

DEWESoft has developed and built MonoDAQ, a high-quality system for measuring the uniformity of flat steel bars. With this measurement data acquisition, it was possible to create a system that measures the uniformity together with the existing sawing process. In doing so, the work cycle is not extended and the measurement results are more accurate than the previous measurement method. Thus, an additional quality inspection is unnecessary - this saves a lot of time.

Which parameters can be measured?

From the physical dimensions of the products to the reaction to test loads (force, vibration or pressure) to electrical properties such as power consumption, everything can be measured both on the end product and during the production process.

Geräte und Software für die Qualitätskontrolle

Distance sensors, load cells, pressure sensors, accelerometers, thermocouples and many other sensors are used in automated quality control systems. Their signals are acquired by data acquisition devices such as the MonoDAQ-U-X and transferred to a powerful software package. The software must be able to perform a large number of mathematical operations "on the fly" to enable the implementation of complex algorithms to determine the final result of a quality control. The result is usually passed on to a PLC via digital I/O terminals, a UDP or TCP/IP network or a standard protocol such as OPC UA.

Automated quality control in production is important

Most high-volume products are offered in very competitive markets. Failures are unacceptable there, so customers demand complete quality control. Investing in modern quality control systems is much cheaper for the manufacturing company than losing customer orders due to poor product quality.

Comparable products

IOLITEI-1XSTG Strain Gauge Amplifier

- Internal bridge completion (quarter & half, 120 & 350 ohm)

- 50 V to 100 mV input voltage ranges

- 20 mA current input range (internal shunt)

IOLITEI-4XDI Signal Conditioner

- 4 isolated TTL/CMOS digital inputs

- EtherCAT bus, daisy-chaining with single cable up to 50 m device-device

- DEWESoft X3 software support

IOLITE Accessories

- IOLITE-POWER-INJECTOR

- IOLITE-REPEATER

- IOLITEDW WATERPROOF ENCLOSURE