What is GNSS and why does it sometimes fail?

GNSS (Global Navigation Satellite System) is a collective term for global positioning systems like GPS (USA), Galileo (EU), GLONASS (Russia), and BeiDou (China). These systems use satellites to deliver precise location and timing data to receivers — such as those on ships and offshore vessels.

However, GNSS signals can become unreliable or unavailable in certain environments, such as:

- Near large metal structures (e.g., cranes, wind turbines, rigs)

- Under bridges or near tall buildings

- During severe weather, signal interference, or multipath errors (signal reflection off water or metal)

- In areas affected by jamming or spoofing

This is a serious risk for offshore vessels relying on GNSS for Dynamic Positioning (DP), especially during precision maneuvers near structures.

The role of inertial navigation (IMUs)

An Inertial Measurement Unit (IMU) doesn’t rely on external signals. Instead, it uses internal gyroscopes and accelerometers to track position, velocity, and orientation by measuring movement directly, a method called dead reckoning. So, when GNSS becomes unreliable or drops out entirely, the IMU fills in the gap, allowing safe continued operation.

Offshore logistics vessels

The customer is a Northern European operator of offshore logistics vessels serving energy companies, wind farm installers, and deep-sea research platforms. The company operates a fleet of offshore support vessels (OSVs) responsible for cargo, crew, and equipment transfers between shore and offshore installations. Their core mission is to ensure reliable and safe transfer of materials and personnel under time-sensitive and harsh offshore conditions.

Due to confidential information, we cannot and do not wish to be completely open about this application. However, we are very pleased and proud of our customer's willingness to allow us to share this project and some of its technical aspects with you.

The need for a sensor-based inertial backup system

When maneuvering close to these structures particularly offshore wind turbines and deep-sea platforms the vessel's GNSS signal can be obstructed by tall metal structures, hulls, or cranes. This causes issues in their existing Dynamic Positioning System (DPS), potentially halting operations or forcing manual override.

The customer needed a sensor-based inertial backup system that could:

- Seamlessly integrate into their navigation control network

- Provide reliable dead reckoning for short-to-midterm GNSS signal loss

- Operate with high precision in challenging sea and vibration conditions

- Reduce the need for frequent recalibration or servicing

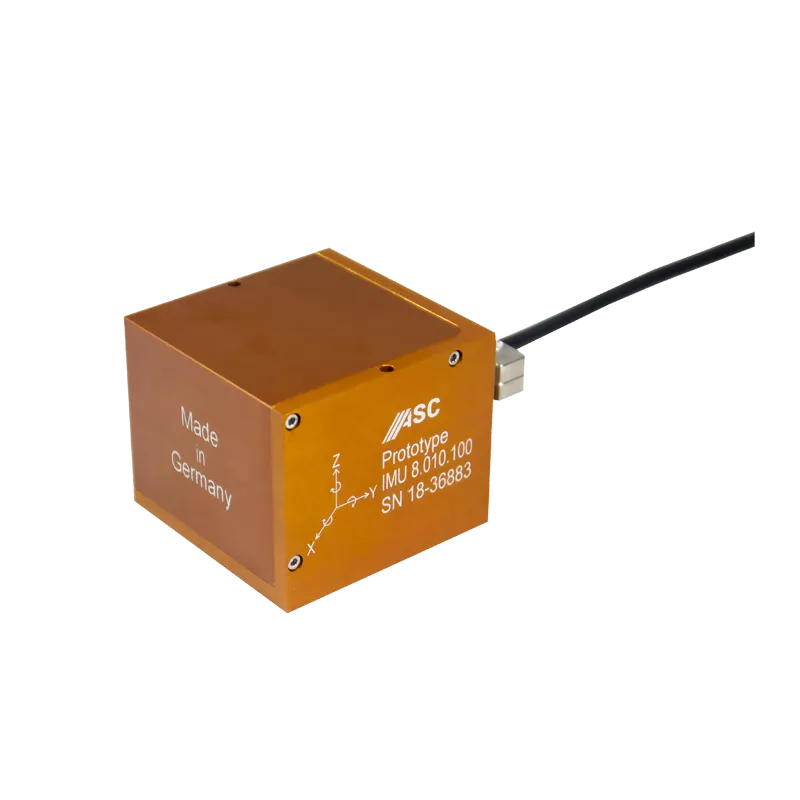

After evaluating several options, ASC’s IMU 8 was selected based on its proven MEMS inertial performance, compact housing, and digital output capabilities.

Product used

High-performance IMU with 6 degrees of freedom (6DoF)

ASC IMU 8.X.Y Tactical grade inertial measurement unit

- Tactical grade IMU with 6 DOF

- FOG-like performance, ARW <0.01 °/√hr

- Modular accelerometer and gyroscope ranges

Project implementation

Following a simulation and evaluation period, the ASC IMU 8 was integrated into the OSV’s DPS software architecture as a fallback sensor module. The system was configured to seamlessly switch from GNSS to dead reckoning based on IMU input when signal degradation was detected.

Sensor installation details:

- Mounted in a shock-isolated enclosure within the ship’s nav cabinet

- Measurement axes 3× accelerometers, 3× gyroscopes (6DoF)

- Wired to the central control unit via RS422

- Data sampled at 100 Hz and fused with shipboard INS software

Field testing took place during live offshore operations, including:

- Close-range docking at a floating wind turbine

- Crane-assisted equipment transfers

- Extended station-keeping in harsh wave conditions (sea state 4–5)

During GNSS interruptions, the DPS continued uninterrupted, drawing on the IMU 8’s output to estimate heading and position with negligible deviation from expected pathing.

-

Reliable fallback during GNSS lossPosition and heading remained stable even when GPS signal was completely unavailable for 30–90 seconds near large metal structures.

-

Safe station-keeping operationsNo system resets or operator override were required, even under rolling sea conditions and structure interference.

-

High integration compatibilityThe IMU 8's RS422 output enabled plug-and-play communication with the ship’s navigation system using standard NMEA sentence structure.

-

Long-term cost savingsMaintenance-free operation and no recalibration required after 6+ months in active deployment.

Minimal disruption to onboard systems

The vessel now has the foundation for integrating hybrid navigation models, useful in autonomous or semi-autonomous offshore logistics scenarios. The customer was able to introduce a hybrid inertial-GNSS navigation capability that elevated operational safety and confidence with minimal disruption to onboard systems.