FGDH-4A Frictional Torque Sensor System

Fast, Strain-Gauge-Free Torque Sensing with Digital Telemetry.

Key features

- No strain gauges on the drive shaft

- Clamp-on installation

- Wireless digital telemetry (2.4 GHz)

- Long operating time – up to 10 hours

- Switchable measuring ranges

- USB rechargeable without removing the sensor

- No calibration required

- Multiple shaft diameter options – Ø20–30 mm, Ø30–40 mm, Ø40–50 mm

About the FGDH-4A Frictional Torque Sensor System

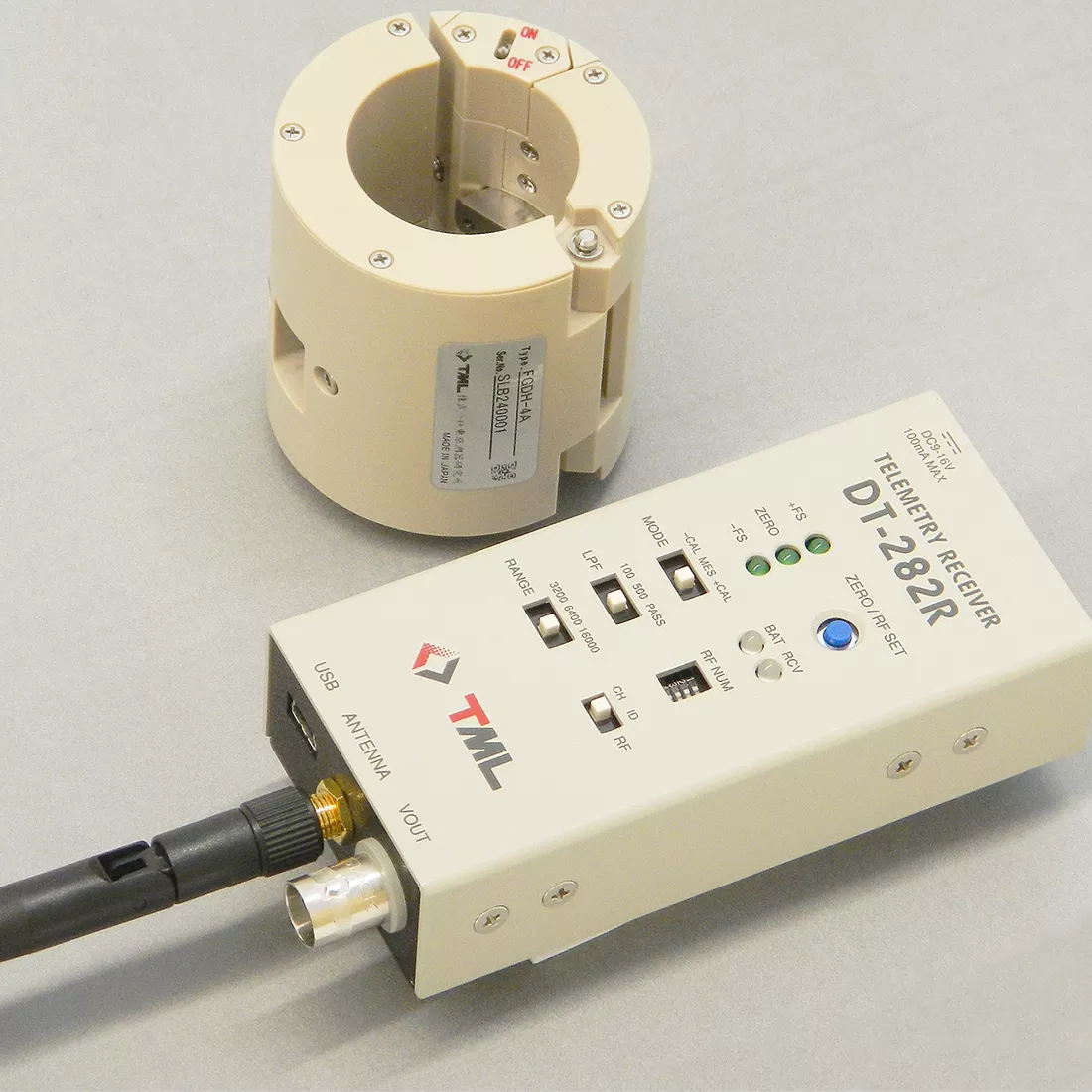

The FGDH-4A is a friction-type torque sensor system designed to measure torque generated on rotating shafts and transmit the data digitally and wirelessly to a dedicated receiver. Unlike conventional solutions that require strain gauges to be bonded to the drive shaft, the FGDH-4A enables one-touch measurement, drastically reducing installation effort and preparation time.

Key benefits

- No strain-gauge installation on the shaft: saves time and eliminates bonding/wiring work

- Fast, simple mounting: clamp onto the shaft and secure with screws

- Wireless digital telemetry (2.4 GHz): long transmission distance and easy antenna setup

- Noise-resistant signal: digital transmitter/receiver system, no cabling required

- Longer operating time: approx. 10 hours (vs. conventional FGDH-3A approx. 6 hours)

- High dynamic response: 1 kHz response frequency

- No calibration required: ready to use quickly

- USB rechargeable: recharge via USB power cable without removing the sensor

- Built-in sleep function: reduces battery drain for extended runtime

Measuring ranges

Switchable between three ranges: ±3200 / ±6400 / ±16000 × 10⁻⁶ strain. This wide range supports measurements from small to large torque amplitudes.

Shaft diameter options

Available for the following shaft diameter ranges (depending on version):

- Ø 20–30 mm

- Ø 30–40 mm

- Ø 40–50 mm

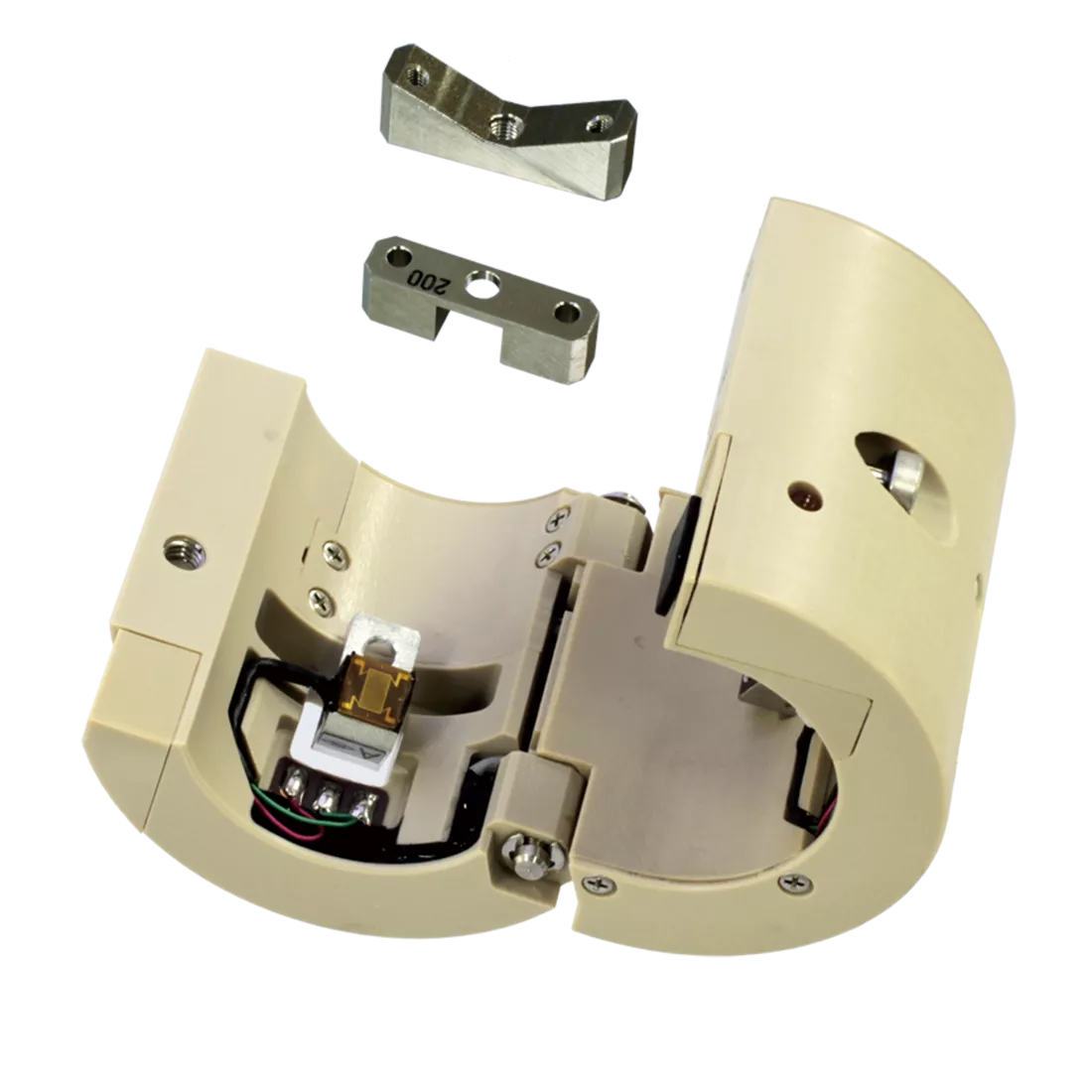

How it works: friction-type sensing

Traditional strain-gauge torque measurement requires surface preparation, bonding, curing, and lead wiring. The FGDH-4A uses friction-type gauges, so no gluing is needed. The sensor is integrated into the clamp-on unit, making installation quick and repeatable.

Digital telemetry for reliable measurements

The integrated digital transmitter/receiver system provides robust, noise-resistant data transmission and simplifies setup by eliminating wiring. High-speed processing also reduces telemetry delay significantly compared to conventional systems.

Regulatory compliance (2.4 GHz)

Compliant with radio regulations in Japan, the European Union (EU), the United States, Canada, China, India, Australia, and the Republic of Korea.

Do you need this sensor for your next project?

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Product downloads

Talk to our experts

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expertTechnical Specifications

| Specification | Value |

|---|---|

| Applicable shaft diameter | φ20.0 ~ 30.0mm / φ30.0 ~ 40.0mm / φ40.0 ~ 50.0mm |

| Capacity | Depends on the diameter (outer and inner), material, surface roughness and surface treatment of the shaft |

| Output | Depends on the diameter (outer and inner), material, surface roughness and surface treatment of the shaft |

| Allowable temperature | -20 to +60 ℃ (No dew condensation) |

| Sampling frequency | 5kHz |

| Frequency response | 1kHz |

| Wireless specifications | Conforms to 2.4 GHz band advanced low power data communication system |

| Number of radio channels | 16 channels (paired with receiver radio channels) |

| External Dimensions | φ52×50mm / φ64×50mm / φ75×50mm |

| Protection rating | Equivalent to IP51 |

| Continuous operating time | Approx. 10 hours (23 ℃ ±5 ℃) |

| Power supply | lithium-ion rechargeable battery |

Related products

Need something else?

SGR510/511/512 Torque Sensor

- Torque range: 0 - 13000 Nm

- Accuracy: ±1rpm up to 30,000 rpm

- Temperature accuracy: ±1 °C

ORT 230/240 Rotating Torque Sensor

- Measuring range: 0,02 to 100 Nm

- Low inertia – High Speed capability

- Non contact/brushless measurement

90415 IRT Rotating Torque Sensor

- Measuring range 100 to 27.000 Nm

- Max shaft speed 15.000 rpm

- Non-linearity 0.05 %