World of Material Testing: Fibre-reinforced Plastics

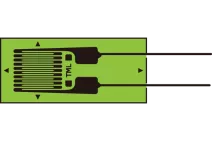

With a customised strain gauge application at Althen, you have the possibility to record the strain occurring on your components. This enables you to draw conclusions about the existing forces and stresses. If stresses on an object are detected in time, components and processes can be optimised and high follow-up costs will be avoided.

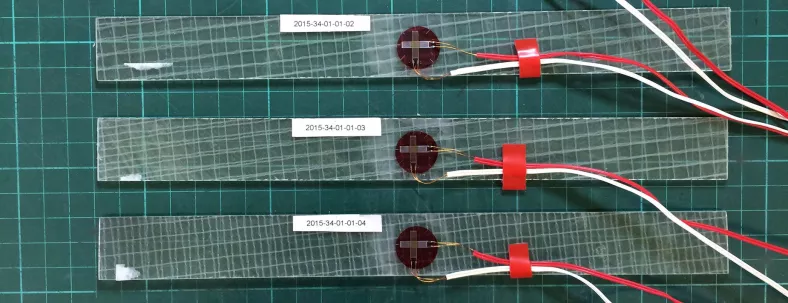

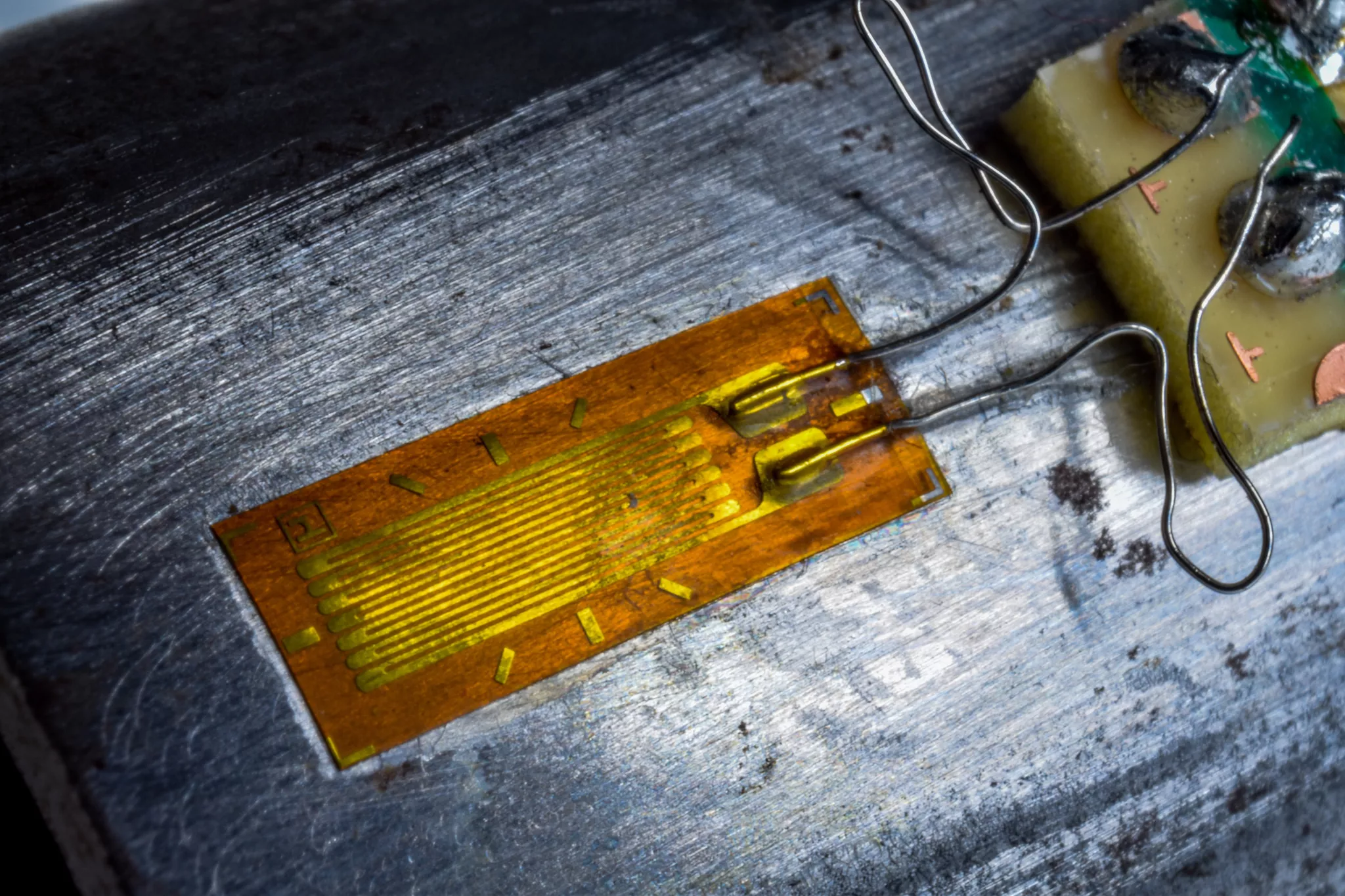

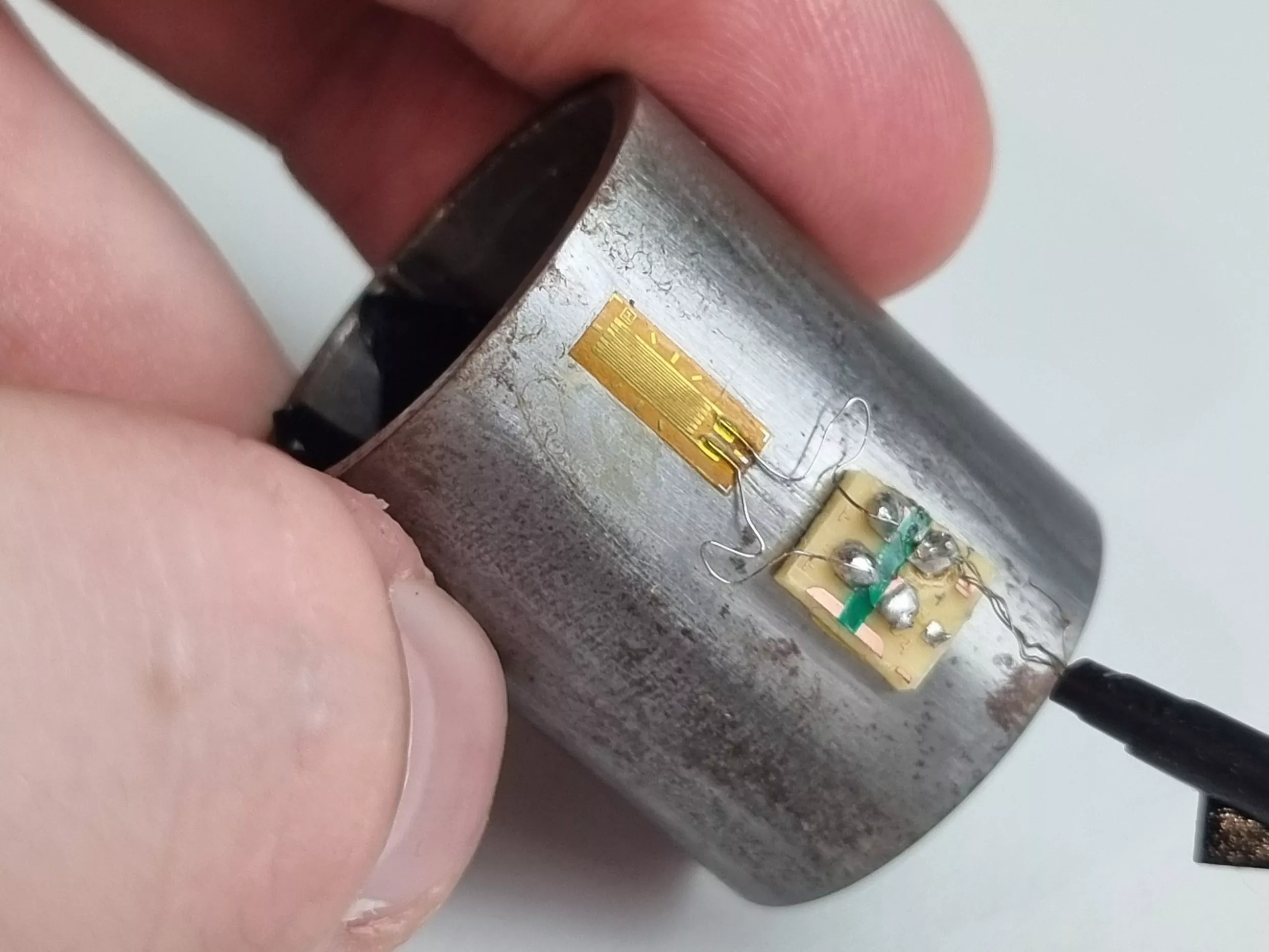

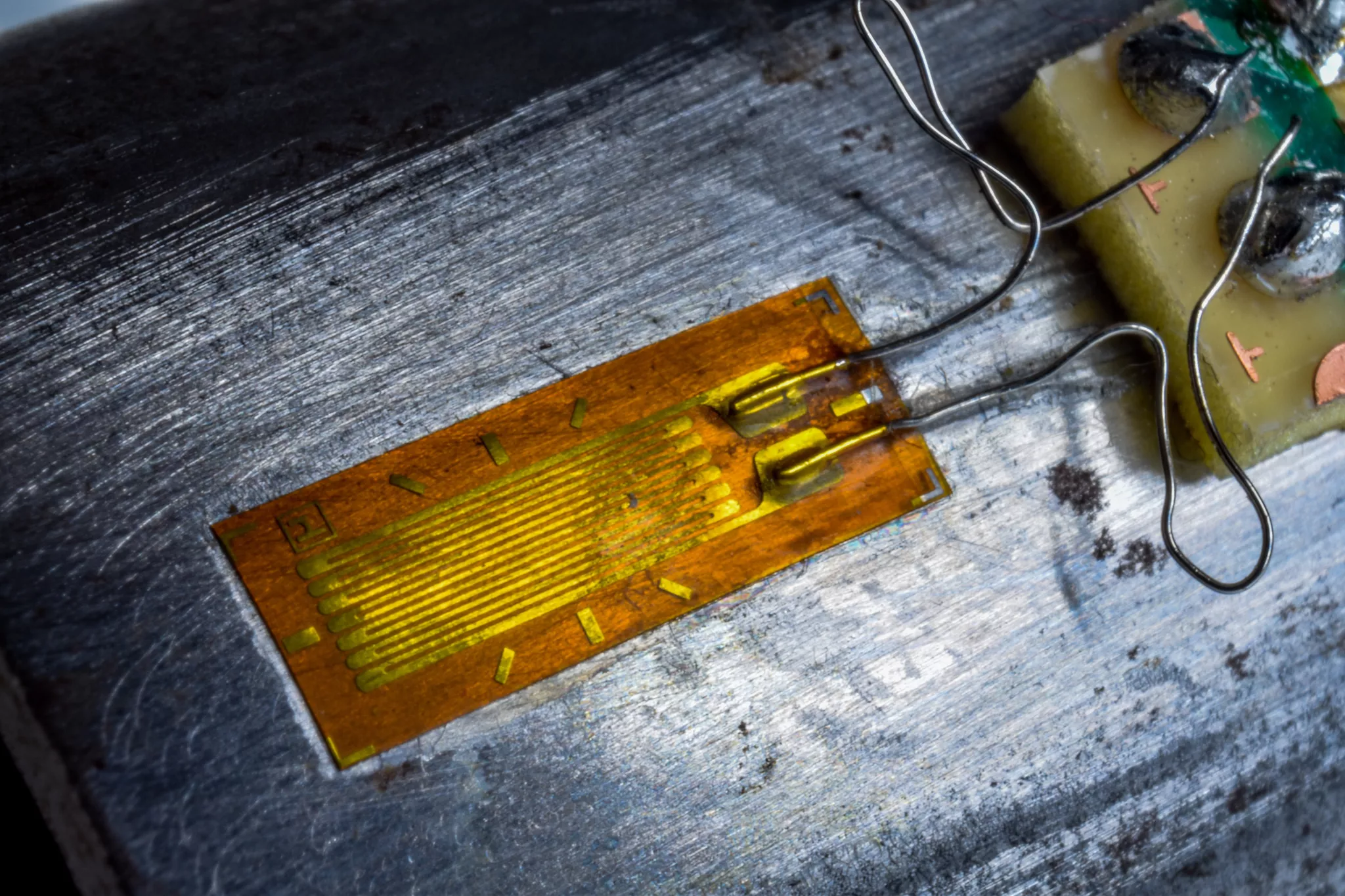

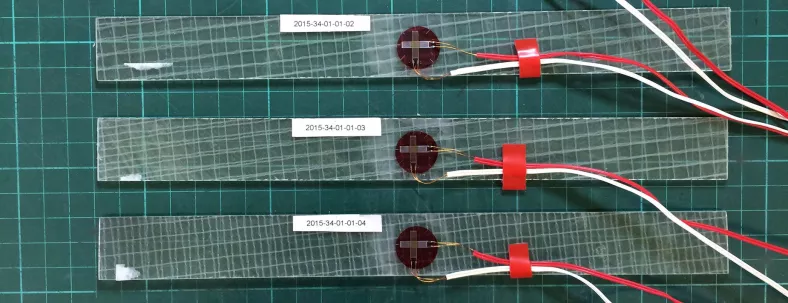

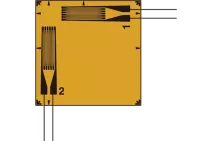

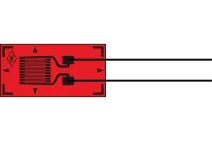

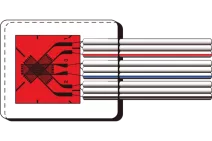

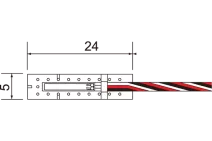

We not only support you in the selection of suitable strain gauges, but also advise you in the determination of the appropriate measuring points. In our in-house laboratory, your components can be subjected to different load cases. The range of services includes bonding and interconnection as quarter, half or full bridges for torsion, bending, tensile and compressive force measurements on metals, plastics, ceramics and glass, as well as other individual services. After completion of the application, you will receive a comprehensive report with information about the strain gauges used, as well as about the bonding process and the results of the calibration.

Do you need budgetary pricing or have questions about our strain gauge service? Let us know how we can help you!