Simple and uncomplicated retrofitting

With the wireless vibration monitoring system from Althen, you can easily refit rotating equipment such as pumps, motors and compressors. There is no special hardware needed. The system consists of wireless battery powered industrial sensor nodes and a gateway for communication to transmit data to the cloud. For evaluation and visualisation, we offer an extensive dashboard solution which can be adaped to all your individual data analysis requirements. Turn you machines from old to smart now!

Industrial vibration & temperature sensor node

- Temperature

- v-RMS*, v-Z2P*, v-P2P*,

- Kurtosis*, v-FFT data*

*in 3 axes (X,Y,Z)

Industrial vibration & temperature sensor node 6

- Temperature

- v-RMS*, v-Z2P*, v-P2P*

- a-RMS*, a-PEAK*, a-P2P*

- Kurtosis*, Crest*, a-FFT data*

*in 3 axes (X,Y,Z)

Also available in an ATEX version.

Ambient sensor node

- Temperature, Humidity, Air pressure

- Ambient light (lx)

- CO2 Index, Air quality

- Movement level

Industrial IoT Gateway

Industrial IoT Gateway collects, processes, and transmits data from sensors to any cloud backend over a wide range of wired and wireless connectivity. It can be freely configured, extended, and run customer edge applications to enable any IoT solution.

Gateway enclosure

Industrial IoT Gateway water and dustproof enclosure is designed to protect the Industrial IoT Gateway in outdoor or harsh indoor conditions. The enclosure includes a gateway AC/DC power supply and DC cable.

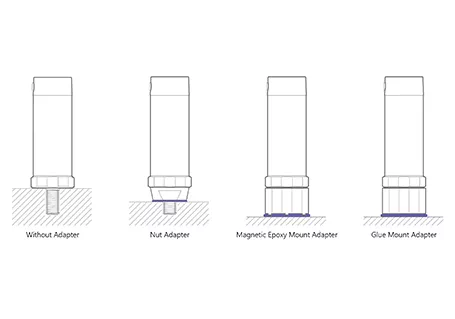

Installation

There are four possible installation methods for the nodes: without adapter, nut adapter, magentic mount adapter and glue mount adapter. The best location to attach the sensor depends on the machine and the monitored vibration source. Ideally, the contact surface on the machine should be completely flat, smooth and larger than the base of the sensor.

-

Cost-efficientCost-effective solution that does not break the budget even when using many sensors.

-

Easy to deployThe sensor can be screwed, glued or magnetically attached.

-

ATEX version availableCertified for potentially explosive environments (ATEX and IECEx certifications).

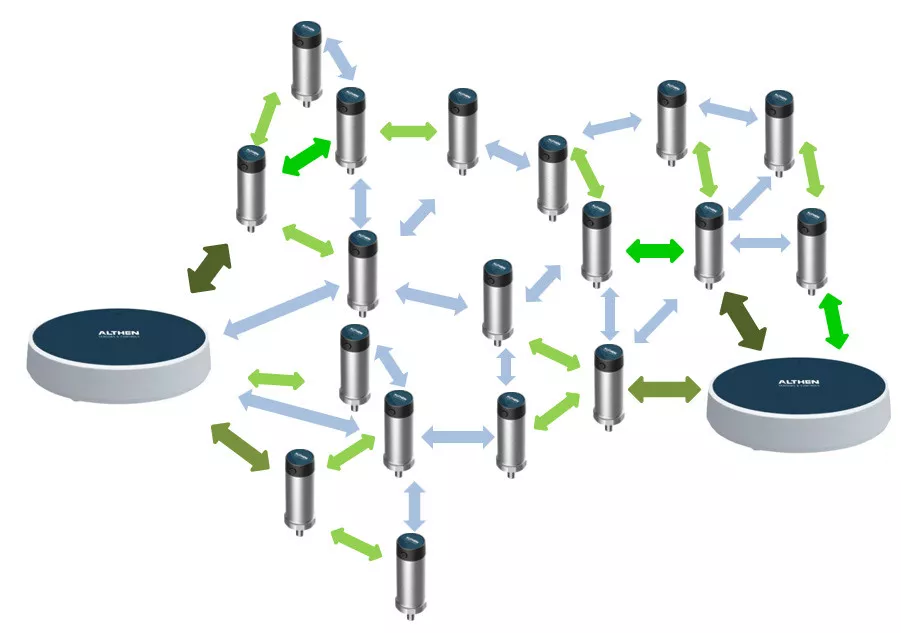

Data transmitting

All data is sent via a so-called "meshnetwork". Each node can forward the data of other nodes to the gateway. Since the range of the nodes depends on the environment, the setup needs to be tested on site and the nodes must be installed accordingly. The sensors automatically search for the best path to the gateway. For very large networks, the use of several gateways is recommended to avoid overloads. In case of changes in the sensor network, the network reorganises itself independently in the upcoming hours.

The sensors have 40 channels and transmit in a frequency range of 2402-2480 MHz (WiFi 2.4 GHz). In the event of interference in the frequency band, the transmission channel is automatically adjusted between nodes in the affected area.

-

Self-organising networkThe network organises itself independently and optimises performance.

-

Automatic channel adjustionChannels are automatically adjusted to avoid sources of interference.

-

Flexible structureNetwork can be flexibly expanded with gateways and nodes at any time.

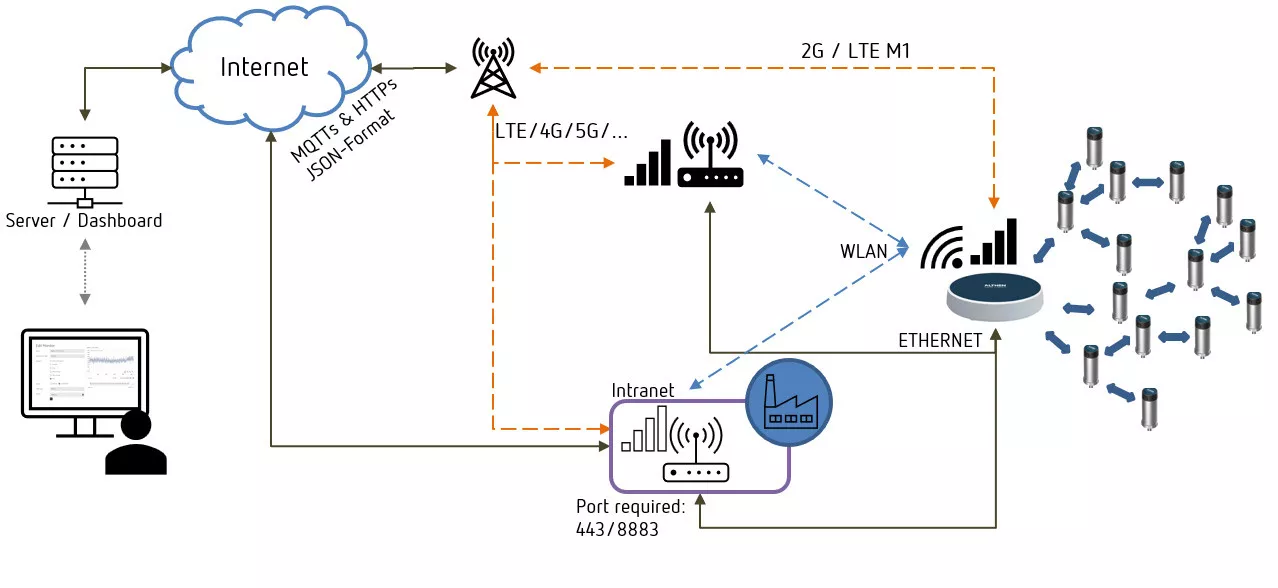

Data transmission & network connection

There are three options available for your network connection:

- Via existing company network (Ethernet/WLAN, requires port 443 or 8883)

- Mobile LTE router (Ethernet/WLAN, independent of the company network)

- Directly from gateway via SIM card (only 2G/ LTE M1)

Whitepaper IIoT

Setting up and commissioning an IIoT solution: from selecting the platform with wireless acceleration sensors to monitoring and commissioning.

-

Transmission repeatEach transmission is confirmed and retransmitted if necessary.

-

SecureSecure and encrypted network.

-

Failure safetyIf a gateway fails, the data is automatically sent to another gateway in the network

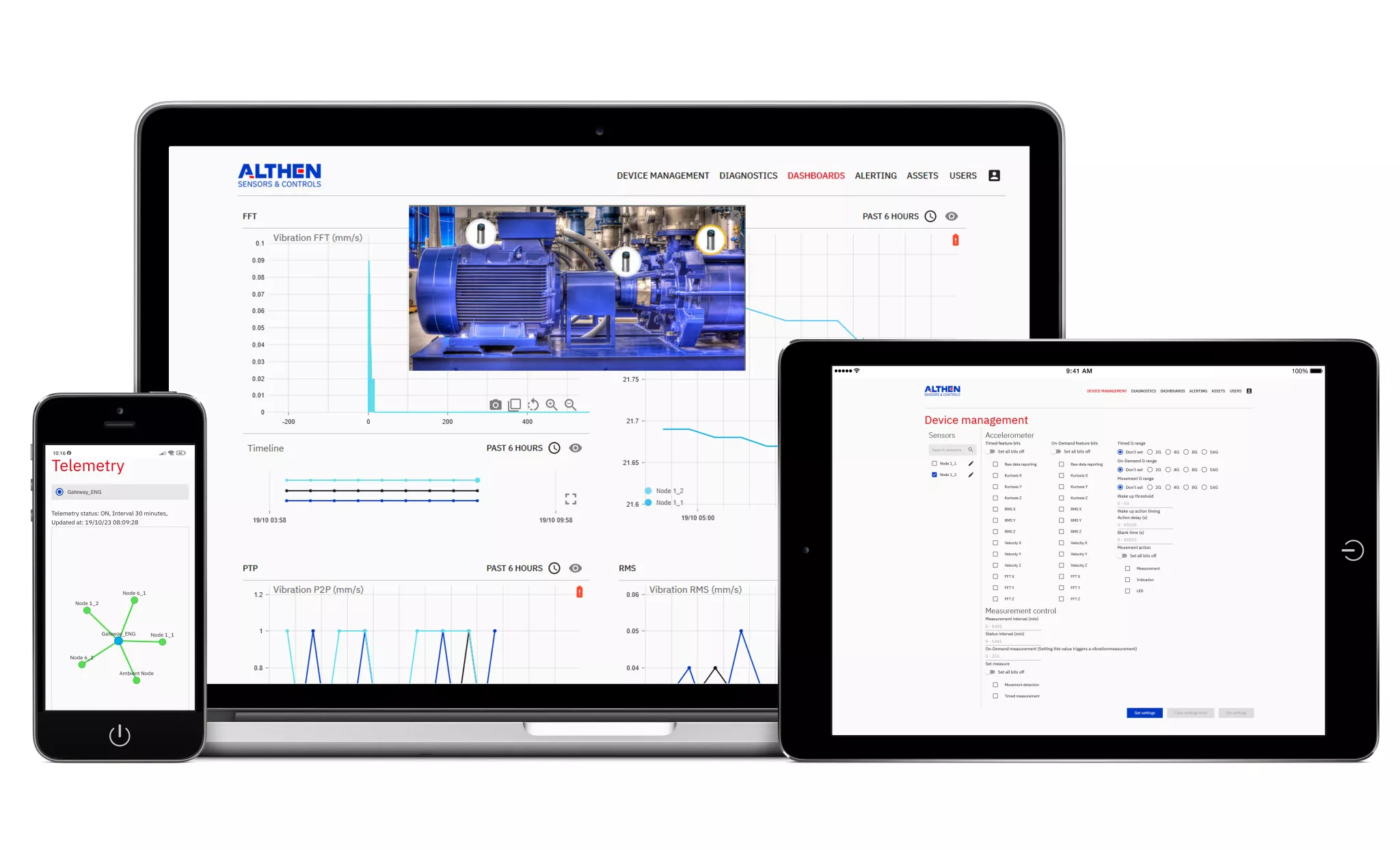

Dashboarding & Analytics

The Althen IoT Monitor offers you a great choice of widgets for different visualizations as well as clear (and fast) overviews for subjects and events, combined with powerful filter and aggregation options. Its clear structure and the well-arranged layout enable every user in the company to get a quick and easy overview of the status of all connected machines.

Monitoring options

- Basic: Threshold trigger on scalar values, Alarm history, Alarm email

- Pro: FFT display, FFT history-based alarm, plus all basic options

- Intelligent: Diagnostic functions, plus all basic and pro options

Intelligent fault detection

- Unbalance

- Parallel misalignment

- Angular misalignment

- Rolling element bearing

- Custom fault

- Eccentricity of stator and rotor

FFT analysis

- Insert interactive FFT graphics in the dashboard.

- Display different calculations separately.

- Monitor new measured values or increased amplitudes based on recorded ones.

- Trigger an alarm in the event of repeated exceedances.

- Update/Extend filters subsequently.

How can we help you?

Do you need advice or help with your IIoT measurement project?