When it comes to non-contact measurement in harsh environments, one technology consistently stands out: eddy current sensing. At Althen, we see firsthand how this principle transforms the way engineers and OEMs approach precision measurement tasks—from machine monitoring to embedded position feedback. But what makes eddy current sensors so special? In this article, I’ll walk you through the fundamentals of eddy current sensing, explain why it outperforms other technologies in specific applications, and share insights from real-world use cases.

What are eddy currents?

Eddy currents are circular electrical currents generated in a conductive material when exposed to a changing magnetic field. Discovered by physicist Léon Foucault in the 19th century, these currents oppose the original magnetic field and can be measured to determine distance, displacement, or vibration.

In sensor terms, eddy current probes use this phenomenon to detect the position of metal objects with extreme precision—without making contact.

How do eddy current sensors work?

An eddy current sensor typically consists of a coil, an oscillator, and a signal conditioner. When the coil emits an alternating magnetic field and a metallic target is present, eddy currents are induced in the target. These currents affect the coil’s impedance, and the change is translated into an electrical signal that corresponds to distance or displacement.

At Althen, our sensors are engineered to detect sub-micron level changes—making them ideal for critical test & measurement and automation scenarios.

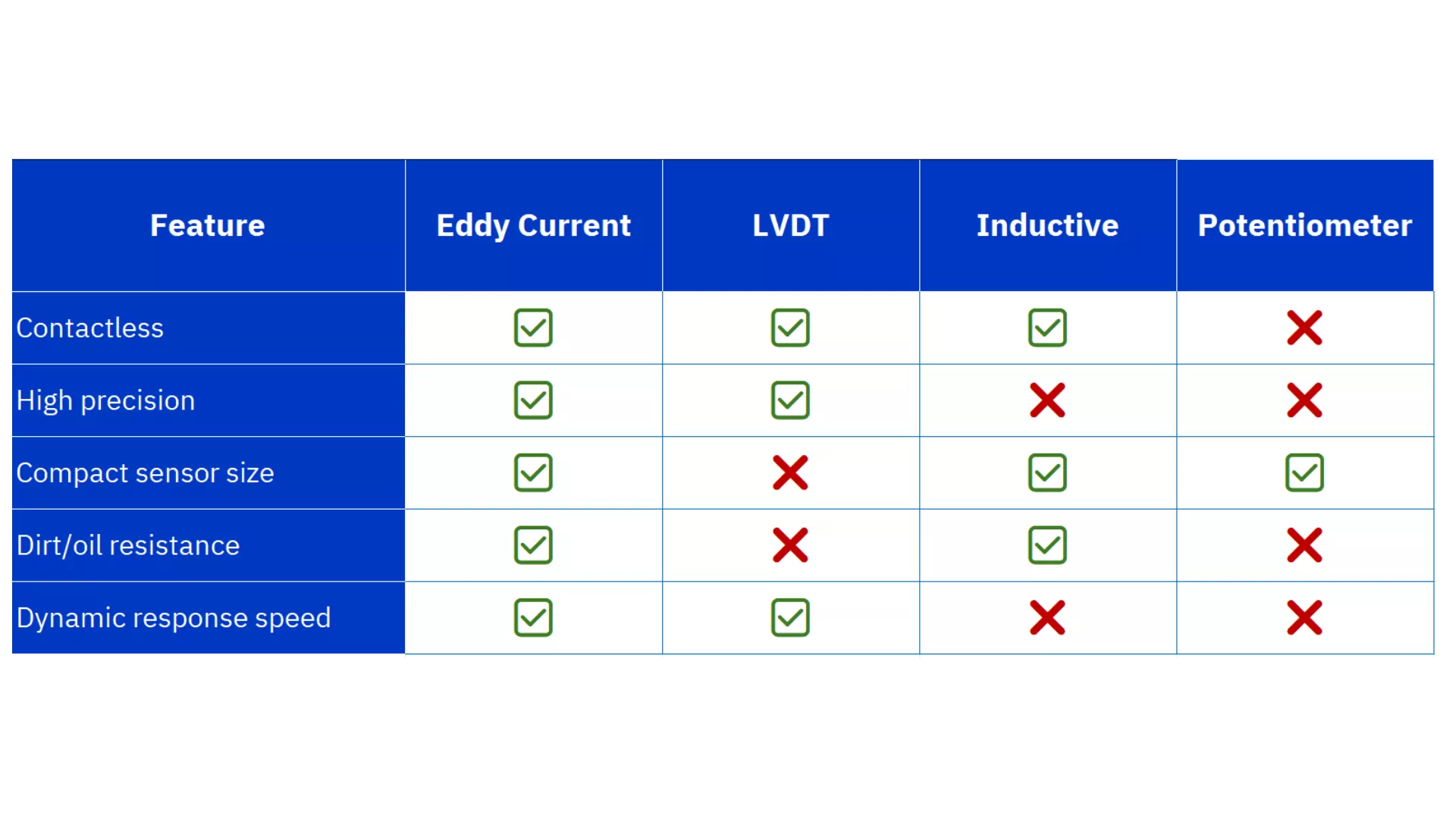

Eddy current vs. other sensor technologies

It’s not uncommon for customers to compare eddy current sensors to LVDTs, potentiometers, or inductive sensors. Each has its merits, but for metallic target detection in challenging conditions, eddy current wins on:

“Once we installed eddy current sensors, we stopped worrying about maintenance and started trusting our measurements.”

Dynamic vs. static measurement applications

One of the key advantages of eddy current sensors is their ability to excel in both dynamic and static measurement environments, but choosing the right model for each is essential. In dynamic applications like shaft vibration analysis, bearing clearance monitoring, or high-speed linear motion, the fast response time and bandwidth of eddy current sensors provide accurate real-time data without signal lag.

On the other hand, for static or slowly varying conditions such as thermal expansion monitoring, structural deformation, or gap measurement in test setups, sensors with high resolution and excellent thermal stability are preferred. Compared to LVDTs or strain gauges, eddy current sensors offer a non-contact, wear-free alternative that performs reliably in contaminated or thermally unstable environments. Knowing your measurement dynamics helps us tailor the ideal sensor solution. Whether it’s fast, slow, precise, or rugged.

Target material influence and calibration

The performance of an eddy current sensor is directly influenced by the electrical conductivity and magnetic permeability of the target material. For instance, a sensor calibrated for aluminum (a highly conductive, non-magnetic material) will respond differently when used on mild steel, which is both conductive and magnetic. These material properties affect the sensor’s sensitivity, linearity, and effective measuring range. That’s why it’s crucial to match the calibration to the actual target material or recalibrate if the material changes.

Signal conditioning & output options

Eddy current sensors offer a surprising level of integration flexibility thanks to multiple signal conditioning options. Whether you're connecting to a simple PLC or a high-speed DAQ system, Althen provides sensors with analog outputs like 0–10V or 4–20mA, or digital formats such as RS232, RS485, USB, or even Modbus RTU. For Industry 4.0 environments, advanced models can support IO-Link or CAN bus, ensuring compatibility with modern fieldbus architectures. Our matched signal conditioners are often pre-calibrated for plug-and-play integration—minimizing setup time and ensuring reliable performance out of the box. If you're unsure which interface works best for your system, our sales engineers are happy to provide a quick selection guide or compatibility table based on your control system requirements.

Common applications we see at Althen

At Althen, we support a wide range of industries. Here are a few examples where our eddy current sensors are making an impact:

Industrial Automation: Precise position control in robotic arms, presses, or stamping machines.

Aerospace: Engineers monitor shaft displacement in turbines or validate test rigs for component fatigue.

Machine Monitoring: Detecting runout, eccentricity, or shaft vibration in critical rotating equipment.

OEM Integrations: Our compact sensors are embedded into hydraulic and pneumatic cylinders for real-time stroke feedback.

Application examples

Two of the most practical applications of eddy current sensing we offer through our Kaman product line are the Air Gap Tool (AGT) and the Thread Checker (TC). The Air Gap Tool is a precision system designed to measure the clearance between rotating components—commonly used in turbines, generators, and motors, where even the smallest air gap variations can lead to efficiency loss or mechanical failure. Meanwhile, the Thread Checker automates the detection of missing or incorrect threads in metallic holes during production, eliminating the need for manual inspection and improving throughput on assembly lines. Both tools leverage the robustness, accuracy, and speed of eddy current technology—demonstrating how this sensing principle supports smart automation and quality control in critical industries.

Practical applications

Eddy current sensing

Air Gap Tool

- Wireless operation via mobile app

- Real-time measurement insight

- USB rechargeable, field-ready

ThreadChecker Non-contact Thread Presence Sensor

- Non-contact thread detection

- Analog and switched output

- Rugged IP67-rated design

Choosing the right eddy current sensor

Not all eddy current sensors are created equal. Choosing the right sensor depends on the measurement environment, target material, and required precision. Here are the key factors we help our customers evaluate:

- Measurement Range: From microns up to several millimeters, depending on your application needs.

- Target Material: Eddy current sensors only work with conductive materials (aluminum, steel, etc.). The material affects calibration and sensitivity.

- Linear Range & Accuracy: For precision-critical tasks (e.g., test benches), choose sensors with tight linearity tolerances and factory calibration.

- Temperature Range: We offer high-temperature sensor variants that can operate up to 200°C or more.

- Signal Output: Choose between analog voltage, current (4–20 mA), or digital outputs depending on your control system.

Need help selecting the right model? Our team supports custom configurations and matching sensors with pre-calibrated signal conditioners for plug-and-play integration.

Installation tips for accurate measurements

Getting the best performance from an eddy current sensor starts with proper installation. Here are 5 tips we always share with customers during setup:

- Maintain Sensor-to-Target Alignment: Misalignment can cause non-linear readings. Mount the sensor perpendicular to the target surface.

- Use the Correct Gap: Stay within the recommended stand-off and linear range for optimal accuracy.

- Avoid Ferromagnetic Interference: Magnetic materials near the sensing zone can affect performance—use shielding if needed.

- Secure the Cable: Prevent cable movement or vibration near the sensor, especially in high-speed machinery.

- Thermal Considerations: If working in variable temperatures, use sensors with temperature compensation or consider thermal drift in your calibration.

Is eddy current right for you?

If you're looking for a robust, precise, and maintenance-free position sensor, especially for metallic targets, then yes. Eddy current sensors could be exactly what you need.