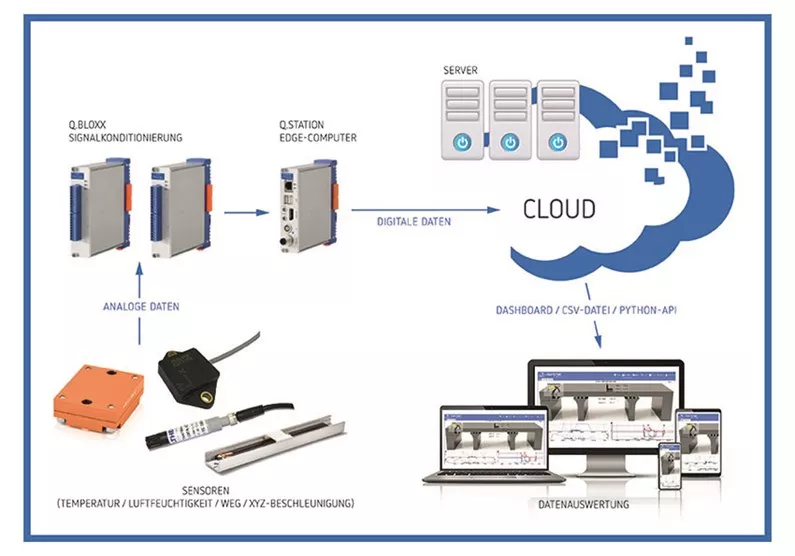

Condition monitoring (CM) refers to the continuous, sensor-based monitoring of the condition of technical systems - especially infrastructure structures such as bridges. The aim is to recognise structural changes, material fatigue or incipient damage at an early stage so that targeted maintenance measures can be initiated in good time. The intelligent combination of sensor technology, data analysis and cloud connection enables risks to be minimised and failures to be prevented.

In the area of bridge monitoring, condition monitoring enables the permanent control of critical parameters such as strain, inclination, temperature, vibration or bearing movements. This applies to both historic bridge structures and modern transport infrastructure. With systems such as inclination sensors, load cells or MEMS acceleration sensors, the structural integrity can be fully documented - often even in places that are difficult to access or over many years.

Advantages of condition monitoring in bridge construction

- Extending the service life of bridge structures: By detecting material fatigue or load changes at an early stage, bridges can be maintained in a more targeted manner and operated over the long term - before critical damage occurs.

- Avoidance of unplanned closures: Closures due to sudden damage cause enormous economic and traffic-related costs. Condition monitoring helps to avoid these by providing warning signals before measures become unavoidable.

- Condition-based maintenance instead of rigid inspection cycles: Instead of rigid time intervals, condition monitoring enables needs-based maintenance. Measures are carried out when the structure requires it - not when the calendar dictates.

Great potential, low realisation

Despite the availability of precise sensor solutions and tried-and-tested systems, condition monitoring has so far only been used selectively on bridges. The reasons for this are often of an economic or organisational nature: uncertainties about the cost-benefit ratio, high initial investments or a lack of legal framework conditions are slowing down widespread use. Added to this is the traditional approach in the construction industry: Visual inspections and periodic checks are still considered the standard - although they often take effect too late compared to continuous monitoring.

The integration of digital systems into existing building structures or the processing of large amounts of data also requires expertise that is lacking or underestimated in many places. One thing is clear: bridges are safety-critical structures whose failure can have serious consequences. Condition monitoring offers the opportunity to take preventative action - and not just react when it is already too late.

Bridge damage wherever you look

The limited use of condition monitoring is directly related to the many bridge damages that are currently visible in Germany and other countries. Much of this damage is the result of decades of neglect, inadequate maintenance and a lack of continuous monitoring. Without regular, sensor-based monitoring, incipient damage - such as material fatigue, cracking or corrosion - often remains undetected for a long time.

Instead of intervening at an early stage, people often only react when there are already acute safety problems. Condition monitoring could provide an early warning here and enable targeted maintenance measures before massive damage or closures become necessary.

The situation clearly shows what consequences a purely visual or cycle-based inspection approach can have: It is often too imprecise and not focussed on the actual condition. Prominent examples include the Rahmede viaduct, the Morandi Bridge (Genoa, Italy) and the Köhlbrand Bridge. A rethink towards smart, continuous monitoring is therefore urgently needed.

Solutions for effective bridge monitoring

Effective bridge monitoring requires precise, reliable and scalable technologies to monitor structural integrity and detect potential risks at an early stage. Althen Sensors offers specialised solutions for this purpose that have proven themselves in various application areas.

SmartBrick: Intelligent inclination sensor solutions

The SmartBrick is an innovative IoT sensor that has been specially developed for monitoring quay walls and bridges. It continuously measures changes in inclination and transmits the data wirelessly to a central dashboard. Thanks to its ultra-low power consumption and easy installation, the battery-powered sensor is ideal for long-term monitoring projects without the need for extensive maintenance.

In the city of Leiden, SmartBrick has been successfully used to monitor the inclination of bridges. The data collected makes it possible to react to structural changes at an early stage and plan maintenance measures efficiently. Through machine learning, the system continuously improves its forecasting capabilities and thus contributes to the safety and longevity of the infrastructure.

Load cells: Precise force measurement for structural analyses

Althen Sensors offers specialised load cells for the precise determination of loads and forces in bridge structures. These sensors enable the precise measurement of weight forces and help to analyse the behaviour of bridges under different load conditions. In one project, load cells were successfully used to weigh a bridge in order to obtain accurate data on the forces acting on the structure. This information is crucial for assessing the load-bearing capacity and planning maintenance measures.

MEMS acceleration sensors: Monitoring of shocks and vibrations

MEMS acceleration sensors are used to detect oscillations and vibrations in bridge structures. These sensors are characterised by their high sensitivity and low noise values, which makes them ideal for monitoring low vibration frequencies. One example of this is the use of the IOLITEdi-3xMEMS-ACC sensor, which, in combination with the DEWESoft software, enables comprehensive analysis of vibration data. This technology supports the early detection of structural changes and contributes to the safety of bridges.

Safety for historic bridges

Many historic bridges in Europe date back to a time when today's traffic and environmental pressures were not yet foreseeable. In a project on a steel arch bridge, capacitive acceleration sensors (e.g. ASC 4411LN, 4415LN) and gyroscopes (e.g. ASC 271) were installed to record micro-vibrations and angular drift under real load conditions. These sensors enable continuous monitoring of structural changes - without interfering with the building fabric. The system recognises critical developments at an early stage, sends automated warning messages and provides a data-based decision-making basis for maintenance and budget planning. Integration into existing asset management systems supports predictive maintenance and increases the service life of the bridges - while at the same time protecting the structural heritage.

Permanent Structural Health Monitoring

Structural health monitoring (SHM) centres on the permanent monitoring of structural integrity. In a project to monitor a cable-stayed bridge, Althen Sensors installed a complex measuring system that permanently records critical parameters such as cable tensions, inclinations and vibration behaviour. Among other things, MEMS acceleration sensors (IOLITEdi-3xMEMS-ACC), digital inclinometers and customised data acquisition systems were used.

The measurement data is recorded automatically and can be evaluated and visualised using software solutions such as DEWESoft. The advantage: seamless historical documentation enables long-term changes and sudden events (e.g. as a result of earthquakes or heavy traffic) to be recognised. This enables condition-based maintenance and significantly reduces the risk of failures.

Conclusion

Successful bridge monitoring requires the use of various sensor solutions that are customised to the specific requirements of the respective structure. With products such as load cells, customised sensor solutions, remote monitoring systems and comprehensive SHM solutions, Althen Sensors offers a broad portfolio for monitoring and analysing bridges. By integrating these technologies, potential risks can be recognised at an early stage and maintenance measures can be planned efficiently, which contributes to the safety and longevity of the infrastructure.

Matching products

Custom special application load cells

- Customized measuring ranges

- Wire rope measurements

- Pedal force measurements

Capacitive accelerometers

- Measuring range: up to ±400 g

- Resolution: up to <1 µg

- Excellent temperature stability

MEMS inclinometers

- Measuring range from ±1° to ±90°

- Accuracy/Resolution up to 0.001°

- One & two-axis versions available

Temperature, humidity & other sensors

- Special for temperature and humidity

- For all data loggers