Accurate torque measurement on shafts is essential for the development, testing, and optimization of modern drive and machinery systems. However, in rotating applications, reliably capturing mechanical loads places specific demands on sensors, signal transmission, and installation. In this article, we show how strain gauges (SG) are used for torsional measurement, what to consider in rotating systems – and what alternatives are available.

Why Measure Torque?

Torque is one of the most critical mechanical variables when it comes to understanding forces and power transmission in rotating systems. It not only provides raw data but enables engineers to draw valuable conclusions about the condition, efficiency, and load of a system.

Torque measurement plays a key role in many areas, such as:

- Test benches for engines and transmissions

- Development of automotive and e-mobility components

- Monitoring of turbines or shafts in industrial plants

- Efficiency improvement and condition monitoring during operation

- Optimization and monitoring in power generation (turbines, generators)

Therefore, accurate torque measurement is far more than a technical requirement – it is a key enabler for improving efficiency, preventing failures, and optimizing systems in rotating applications.

Signal Transmission from Rotating Components

When measuring torque on rotating shafts, strain is typically detected using strain gauges (SG). A crucial aspect is how the measurement signal is transmitted from the rotating shaft to the evaluation unit. There are three proven solutions available for this:

Slip ring systems

These systems transmit the DMS signal from the shaft to the stationary readout unit via rotating contacts (rings and brushes). They are inexpensive, mechanically simple, and well suited for low to medium speed applications. However, they are susceptible to wear and require regular maintenance.

Telemetry systems

With this solution, the measurement signal is transmitted wirelessly—usually by radio or inductively. A miniature amplifier and a transmitter are connected directly to the strain gauge, and power is supplied by battery or inductively. Telemetry systems deliver high-precision data, require little maintenance, and are ideal for high speeds, but they do require a little more integration effort.

Friction torque sensors

These complete systems consist of a pre-assembled sensor module that can be clamped directly onto the shaft without modification. The sensor already contains strain gauges, amplifier, telemetry, and battery. Particularly suitable for temporary applications, retrofit solutions, or when mechanical intervention is not possible.

Torsion measurement with strain gauges: How it works

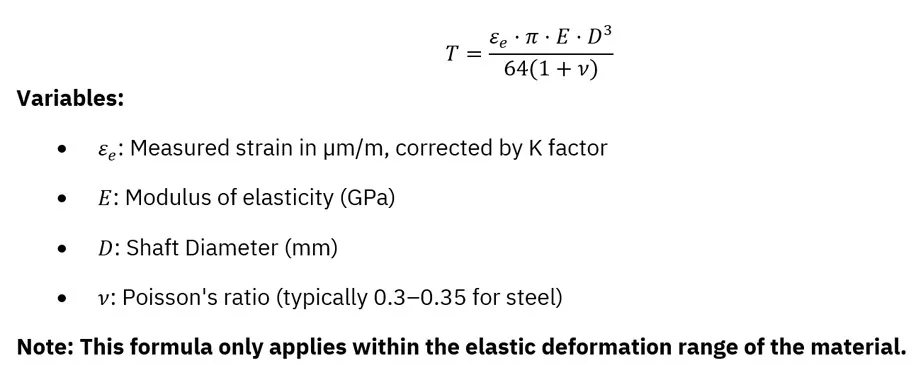

To measure torsion, specialized torsional strain gauges are used – such as the FCT series (F Series). These gauges are aligned at ±45° to accurately capture the twisting (torsion) of the shaft.

Centrifugal Forces and Secure Cabling

In rotating systems, significant centrifugal forces act on all components rotating with the shaft – including strain gauges, connecting wires, telemetry units, and batteries. These forces increase quadratically with rotational speed and can dramatically raise the mechanical stress on components.

To prevent measurement errors, cable breakage, or even damage to the system, careful selection and routing of electrical wiring is essential:

- Use thin, lightweight cables to reduce centrifugal forces acting on the cable mass.

- Ensure that solder joints and transitions between the strain gauge and cable are mechanically relieved and fixed in place – e.g., using adhesive tape, heat-shrink tubing, or appropriate bonding agents.

- Avoid loose or freely suspended cables, as these may vibrate or tear during rotation.

- Route cables flat along the shaft surface, and angle them in the direction of rotation to prevent loop formation.

- At very high rotational speeds, consider adding a protective sheath or guide to shield the wires from abrasion and impact.

- The telemetry unit or slip ring assembly must be mounted centrically and securely, as even small imbalances can cause vibrations.

A proven practical tip: test the cable routing at low speed before final fixation, and if needed, monitor the setup using a camera or laser alignment tool.

Alternative: Friction-Type Torque Sensors

For existing shafts or systems with limited accessibility, so-called friction-type torque sensors offer a practical solution. These systems typically consist of:

- A mechanical clamping collar (customized to the shaft diameter)

- A sensor unit that detects torsion via frictional contact

- An integrated module with amplifier, transmitter, and battery

Key advantage: No drilling or modification of the shaft is required. Installation is quick and easy – even in the field.

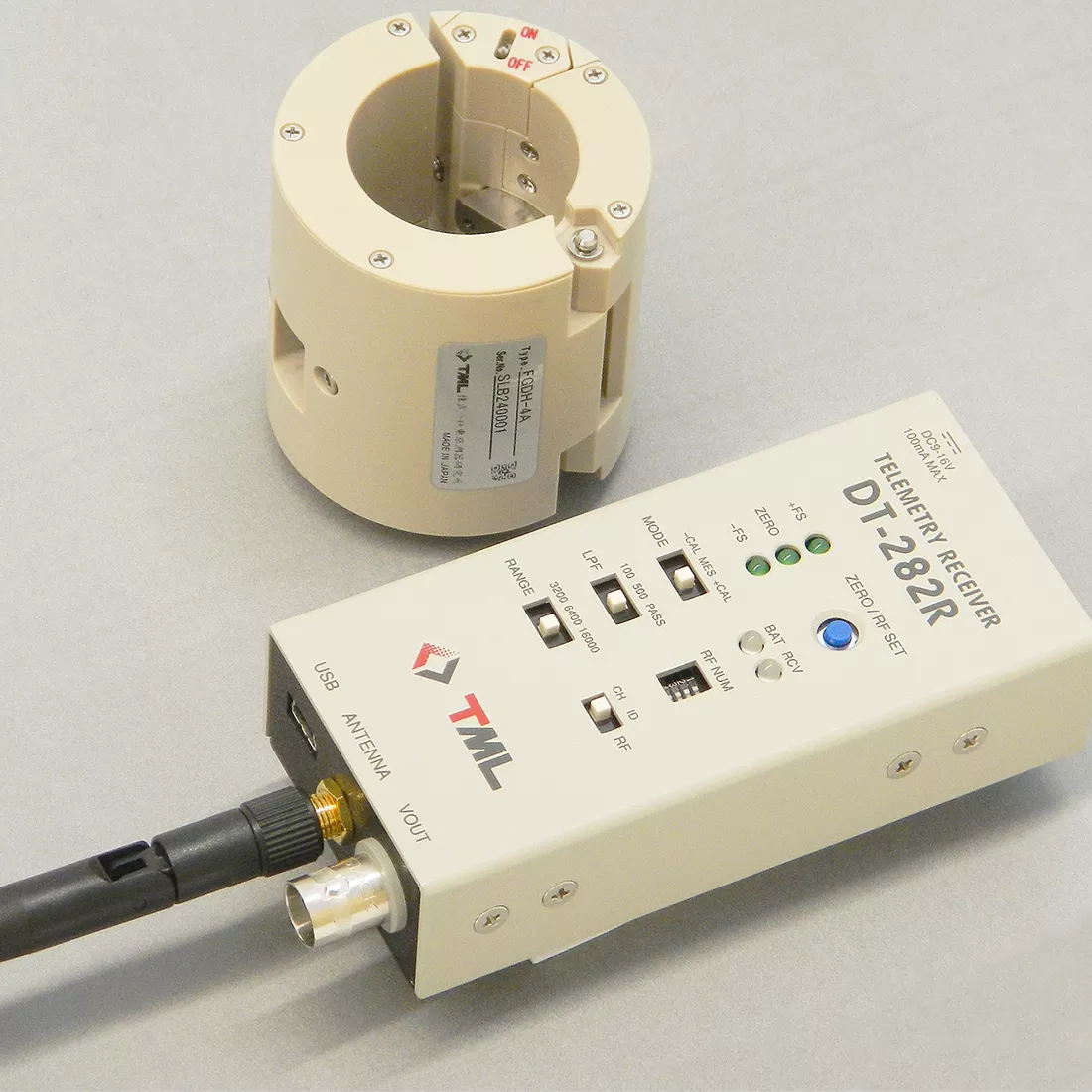

Example: FGDH-4A friction-locked torque sensor system

The FGDH-4A is an advanced torque sensor system designed for non-contact measurement of torsional strain on rotating shafts – without any mechanical modification to the shaft.

Key Features

- Measurement Principle: Friction-locked coupling combined with strain gauge technology

- Installation: Clamp-mounted sensor directly attached to the shaft via a precision-fit clamping device

- Signal Transmission: Integrated telemetry system for wireless data transfer

- Power Supply: Built-in battery with up to 10 hours runtime – ideal for mobile measurement campaigns or temporary testing setups

- Measurement Ranges: From ±3200 µε to ±16000 µε

Thanks to its easy handling and universal applicability, the FGDH-4A is especially suitable for situations where conventional torque sensors are too complex, expensive, or mechanically unfeasible.

Matching products

FGDH-4A Frictional Torque Sensor System

- One-touch measurement

- Clamp-on installation

- Wireless digital telemetry (2.4 GHz)

F Series GOBLET Foil Strain Gauges

- Resistance Ω: 120, 350

- RoHS2 Directive Compliant

- Operating temperature range −196〜+150℃

Conclusion: Which torque measurement solution is right for you?

The ideal torque measurement solution depends heavily on your specific application, environmental conditions, and requirements for accuracy, integration, and flexibility.

- For highly dynamic test benches or research laboratories, strain gauge-based systems like the FCT series in a full-bridge configuration, combined with a telemetry unit, are recommended. This setup offers high precision and comprehensive data acquisition during rotation.

- For pre-series testing or temporary measurements, friction-coupled torque sensors such as the FGDH-4A are a smart choice: easy to install, non-invasive, and highly flexible.

- In stationary or low-speed systems, a slip ring solution can be sufficient and cost-effective for short-term use.

- For OEM applications, special attention should be paid to compactness, robustness, and ease of integration into existing systems.

The best solution is the one that integrates seamlessly—both technically and economically—into your application while delivering reliable and traceable measurement results.