EP turn Absolutdrehgeber

Programmable incremental encoders series

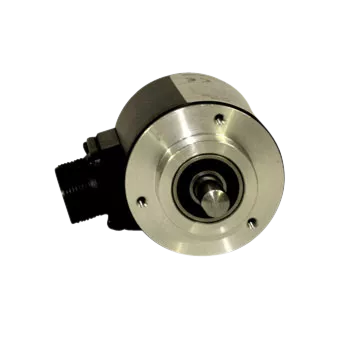

EP/REP - Programmable Magnetic Incremental Encoders

- Pulses per revolution: 8 - 2048

- Pulse code: Incremental

- Output signals: push/pull or line driver

- Shaft Ø: 6, 8, 9.52 or 10 mm

- Protection degree: IP64 (optional IP65)

- Operating temp.: 0 ÷ 70°C

Features EP/REP

- Magnetic incremental encoders

- Programmable ppr number

- Zero pulse

- Several configurations available

- Accurate, strong and reliable

Incremental encoders EP/REP ppr no. ranges from 8 to 2048. The ppr no. is easily set by the user directly via PC; the programming kit supplied with the encoder includes the USB cable ended with the encoder connector, and the CD with the programming software.

EP/REP operate according to the magnetic principle, and offer excellent performances in terms of resistance to vibrations and shocks, acceleration, speed and protection.

The different mechanical versions can meet every type of application requirement; each mechanical type is available with ABS plastic case – series EP with push-pull output – or metal case – series REP with line driver output.

Type EP

- ABS plastic case

- Push-pull electronic output

- 7-pin MS connector axial or radial outlet

Type REP

- Aluminium case

- 5 Vdc or 5/28 Vdc line-driver output

- 12-pin Connei connector axial or radial outlet

Mechanical versions

Series EP/REP521:

- Round flanged, Ø 58 mm,

- Servo coupling

- Ø 50 mm centering mask

- Shaft Ø: 6, 8, 9.52 or 10 mm

Series EP/REP511:

- Round flanged, Ø 58 mm

- Servo coupling

- Ø 31.75 mm centering mask

- Shaft Ø 6, 8, 9.52 or 10 mm

Series EP/REP621:

- Square flanged 63.5 x 63.5 mm

- Centering mask Ø 31.75 mm

- Shaft Ø: 6, 8, 9.52 or 10 mm

Series EP/REP541:

- Round flange Ø 58 mm, servo coupl.

- Centering mask Ø 36 mm

- 3 M4 holes at 120° on Ø 48 mm

- Shaft Ø 6, 8, 9.52 or 10 mm

Series EP/REP651:

- Square flange 63.5x63.5 mm

- Centering mask Ø 50 mm

- Shaft Ø 6, 8, 9.52 or 10 mm

Series EP/REP411:

- Round flanged,

- Ø 63 mm Hollow shaft for direct mounting to a motor shaft,

- Hole diameter 8, 10, 12, 14 or 15 mm

Series EP/REP401:

- Round flange,

- Ø 58 mm,

- Fixing holes on Ø 30 mm

- Joint for direct mounting to a motor

- Shaft diameter 6, 8 or 10 mm

Series EP/REP471

- Round flange,

- Ø.72 mm,

- Fixing holes on Ø 63.5

- Joint for direct mounting to a motor

- Shaft diameter 6, 8 or 10 m

Benötigen Sie dieses Produkt für Ihr Projekt?

Fordern Sie jetzt ein unverbindliches Angebot an oder senden Sie uns Ihre Kontaktdaten für eine unverbindliche und kostenfreie Beratung. Unsere Vertriebsingenieure setzen sich so schnell wie möglich mit Ihnen in Verbindung.

Produkt Downloads

Sprechen Sie mit unseren Experten

Nicht das richtige Produkt? Wir bieten Standard-Sensoren, helfen Ihnen aber auch gerne mit einem maßgeschneiderten Aufnehmer oder einer kompletten Messlösung weiter. Kontaktieren Sie uns einfach für eine kostenlose Beratung oder einen Kostenvoranschlag.

KontaktTechnische Spezifikationen

| Spezifikationen | Wert |

|---|---|

| Case material | EP: ABS / REP aluminium |

| Connection outlets | MS 7-pin axial or radial connector (push-pull output) or Connei 12-pin axial or radial connector (line driver output) |

| Electronic output | Push-pull or line driver - Signals protected against short circuits |

| Inertia | ≤25g cm2 |

| Max. frequency | 200 KHz |

| Max. load | 80N axial/100N radial |

| Output signals | Two square waves 90° ±15° out of phase - Zero pulse width: 90°±15° |

| Power consumption | 1.2 W |

| Resolutions/minute | 6000* continous 10000 temporary (*max operating speed with IP65 sealing ring applied on the shaft: 3000) |

| Shaft material | Stainless steel AISI 303 |

| Shock resistance (11 ms) | 50 G |

| Starting torque | ≤ 0,8Ncm |

| Stocking temp. | -20 ÷ 80°C |

| Supply voltage | 5/28 Vdc - Protection against polarity reversal |

| Vibration resistance (10÷2000 hz) | 100 m/sec2 |

| Zero pulse | 1 pulse each resolution |

Ähnliche Produkte

Benötigen Sie weitere Informationen?

EMA Singleturn Absolutdrehgeber

- Shaft: 6, 8, 9.52, 10, 11 mm

- Protection degree: IP64, optional IP65 (version K)

- Operating temp.: -30 ÷ +70°C

MRE Singleturn Absolutdrehgeber

- 8 to 13 bit resolution

- SSI, parallel or analogue output

- Detection of displacements on machines

MEM Single-turn Absolute Rotary Encoder

- 8 to 13 bit resolution

- Reaches high acceleration and speed values

- High resolution, Binary or Gray code