Smart tram monitoring in The Hague with Althen’s 3D Wheel+ System

Accept the marketing cookies to view this video.

Click here to change your consent.

Accept the marketing cookies to view this video.

Click here to change your consent.

An advanced stationary measurement system for Weighing in Motion, Wheel Flat Detection and Train Detection

Our AWIM Weighing in Motion System is a stationary measurement system able to function as a dynamic weighing scale. This advanced in-motion system is used for Weighing in Motion, Wheel Flat Detection, Train Detection and much more!

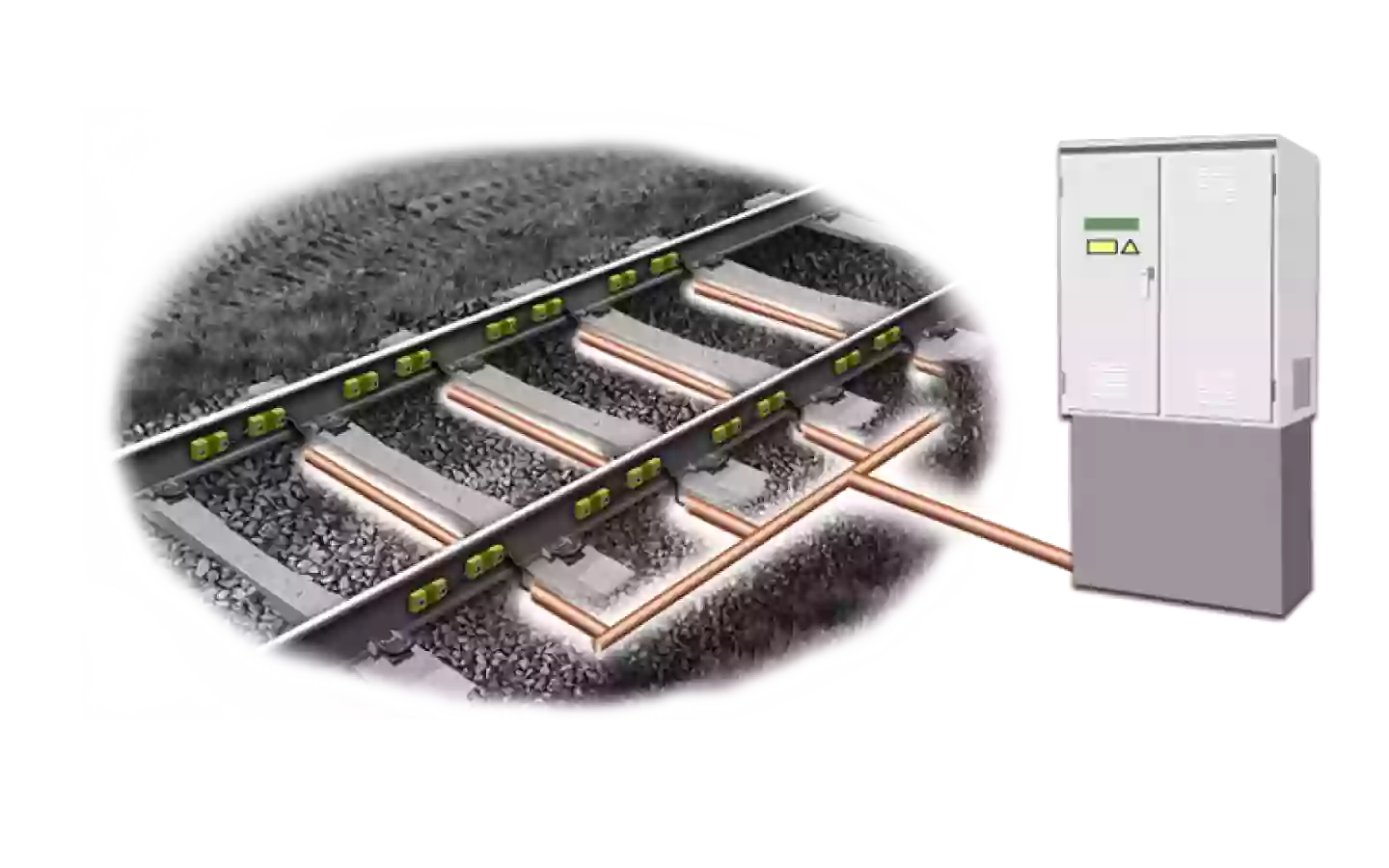

It consists of various passive non-moving parts that are mounted on the side of the railbeam.

These sensors are then connected into a network and special electronics combine all signals using specific algorithms. Various parameters are calculated and logged together with unique vehicle identification features.

The AWIM system offers the following measurements and safety parameters:

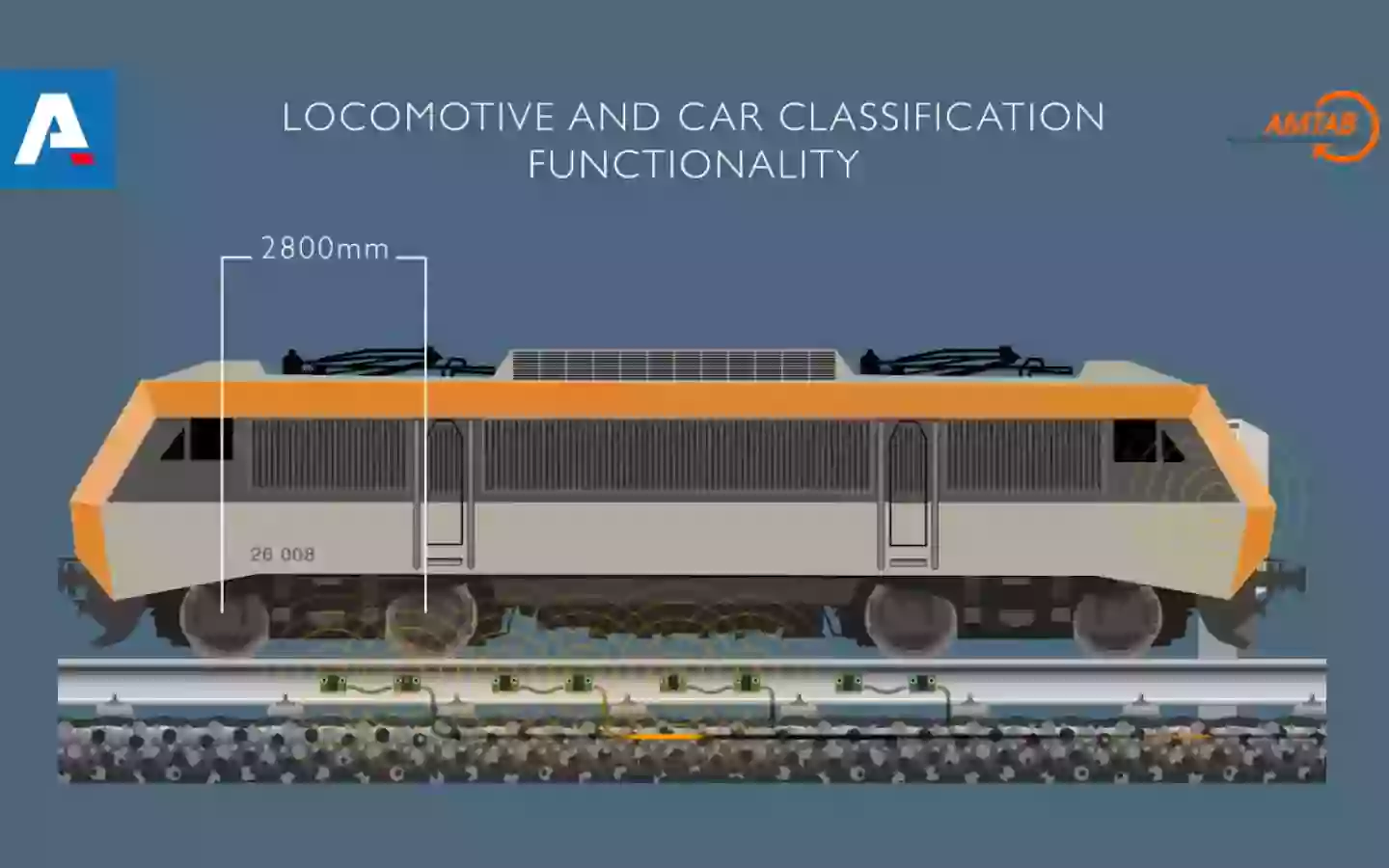

The accuracy of this system is based on measuring a complete train, consisting of a locomotive and various cars. Our AWIM System is equipped with eight weighing points. Formal tests by the Technical Research Institute of Sweden show even an average accuracy of ±0,2%. The internationally recognised Netherlands Measurement Intitute (NMi) has certified the system as OIML Class 0.5.

When combining all measurements an overall accuracy of better than ±0,5%* is achieved for passing trains with various speeds, complying with OIML R106, class 0,5.

In order to identify the vehicle, the locomotive- and wagontype can be determined by our system thanks to an integrated algorithm comparing distances between passing wheels and bogies. In addition extra features can be added to increase identification of vehicles and axles. We offer an integrated RFiD scanning system and as well Vision Technology Cameras to register the vehicle number and axle ID’s.

Furthermore our AWIM system can easily be combined with our laser 3D Automated Wheel Measurement System. To include diameter, back2back and the complete wheel profile of all wheels!

The system-cabinet installed just next to the track houses all electronics and processing units. All sensors are connected to this system and signals are being processed in real-time. The raw measurements are processed, analyzed and converted into ready-to-go data and results. These can be monitored and logged remotely, fast, save & easy!

* The Weighing in Motion system is very accurate and remains accurate at high speeds. But at the same time we need to take into consideration that a train at high speeds will ‘woble’ alot more and increase the impact on the sensor causing more weight and thus increasing the weighing error.

When choosing a location for a dynamic weighing system or scale it’s also important to select a location where acceleration and breaking of trains is reduced to a minimum, weighing a passing train at a more or less steady velocity will generate a reliable measurement. For this reason the chosen location should be as straight, flat and stable as possible.

Request a no-obligation quote or send us your contact details for a free, no-obligation consultation. Our sales engineers will then contact you within a maximum of 1 to 2 working days.

Not exactly what you are looking for? We offer standard sensors, but can also help you with sensors adapted for you or a fully customised measurement solution. Contact us for advice or pricing.

Talk to an expert| Specification | Value |

|---|---|

| Accuracy | 1-0,5% depending on configuration |

| Classification | OIML R 106 |

| Communication interfaces | USB, RS-232, RS-485, TCP/IP 10/100Base-T Ethernet |

| Consumption (with heater) | Normal: <80 W (250 W), Max: 210 W (350 W) |

| Environment protection | IP67 |

| Graphical user interface | Built-in webbased interface |

| Measurement range | Limited to rail type, max. load specification |

| Operating temperatures | -30°C to 80°C |

| Power | 100 - 240 VAC, 50-60 Hz, 6 A |

| Storage | CompactFlash® Card / External MySQL™ Database (optional) |

| Transport weight | 100 kg |

Need something else?