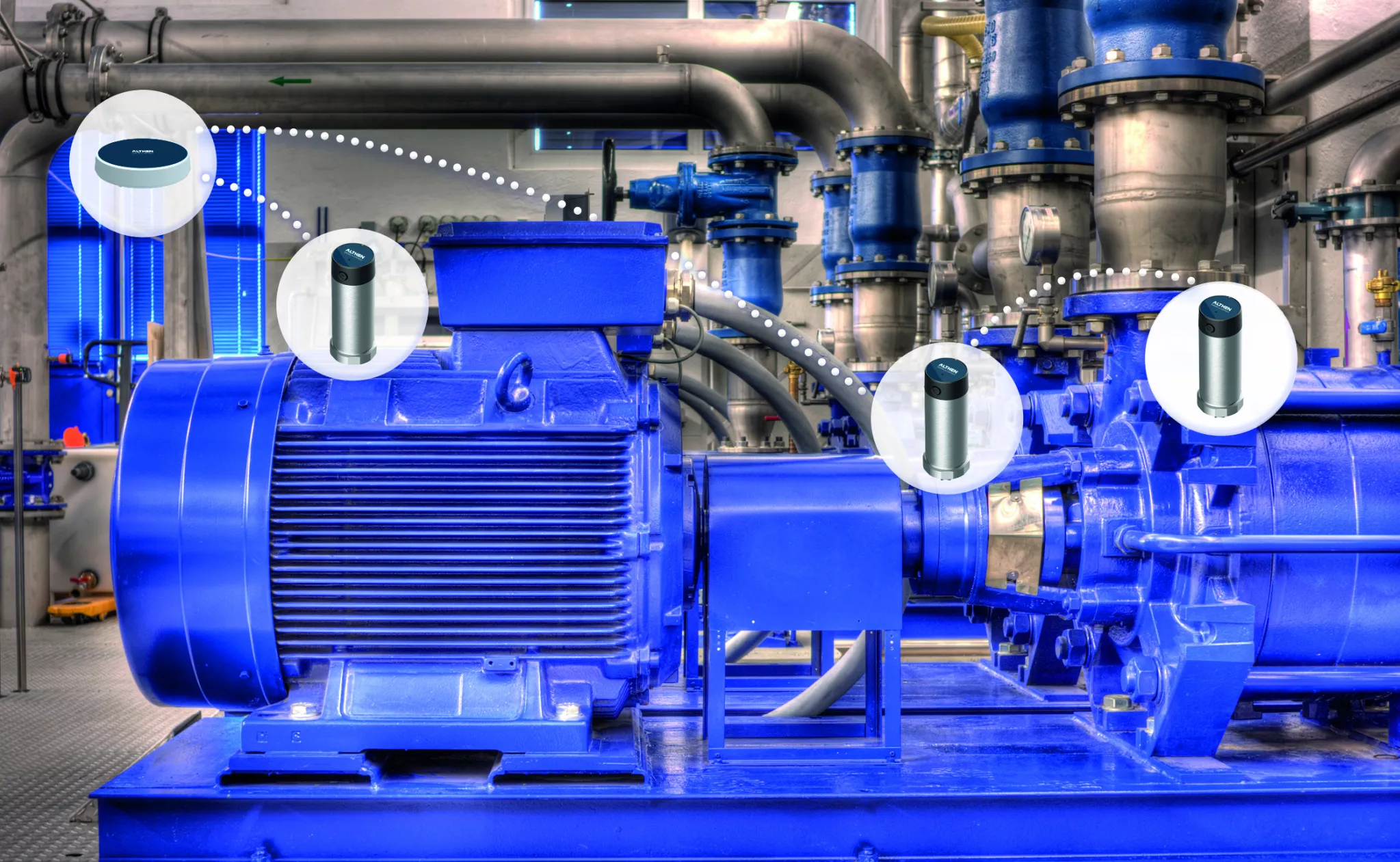

New industrial plants usually benefit from integrated condition monitoring tools. Existing systems often lack these tools, making predictive maintenance difficult. Measurement specialist Althen offers a condition monitoring system for existing systems with rotating parts - such as motors, gearboxes, pumps or fans - that is easy to retrofit. Wireless vibration sensors communicate the measurement data wirelessly to a gateway, which then transmits it to a cloud. Althen has developed a monitoring solution for data analysis that offers a wide range of clear evaluation options.

Predictive condition monitoring is crucial for machines with rotating system parts in order to detect wear at an early stage, avoid breakdowns and ultimately save costs if wear parts need to be serviced in good time and replaced as planned.

Althen offers a measurement solution for vibration measurement and condition monitoring consisting of wireless, battery-operated vibration sensors that transmit the measurement data to a cloud via gateways, as well as the "Althen Monitor" for data evaluation. These measuring nodes contain an acceleration sensor, which measures vibrations in three directions, and a temperature sensor. All signals are processed in the sensor itself.

Vibration measurements usually generate a lot of raw data, which requires a large volume of data to be transmitted wirelessly. To avoid such a volume of data, intelligent vibration sensors from Althen are used that do not transmit the raw data unfiltered. Instead, the measuring nodes are informed in advance which vibration acceleration data is to be processed and transmitted.

Reduce raw data thanks to intelligent sensors

This includes the definition of time intervals or the transmission of critical limit values. The following values can be output: a-RMS/p2p/z2p (peak-to-peak/zero-to-peak), v-RMS/p2p/z2p (peak-to-peak/zero-to-peak), crest factor, kurtosis, temperature. This saves data and also reduces the load on the network if, depending on the measurement task, not just one measurement node but a larger number of sensors are installed. Data is transferred via a network of several vibration sensors that communicate with each other and with the gateways used (SSL encryption TLS 1.3).

Self-organising mesh network

Communication does not just run from one measuring node to another defined measuring node or gateway, but the sensors always look for the best communication path, i.e. the shortest or the one with the strongest signal. The systems work as energy-efficiently as possible so as not to put unnecessary strain on the batteries. Depending on the system situation and available space, one gateway is responsible for radio communication for up to 25 sensors.

The customer first defines the number of machines and systems they want to monitor. This determines the number of measuring nodes required. For the corresponding gateways, it must be checked whether the areas in question are open or enclosed spaces and what materials are present, e.g. any steel or reinforced concrete structures that could impair the signal. Sufficient gateways with a sensible distribution must be used to ensure good network and data quality. The network can be expanded or reduced at any time by adding measuring nodes and gateways as required. It organises and reorganises itself independently. The wireless vibration sensors and the gateway are also available in an ATEX-certified version for use in potentially explosive atmospheres.

Monitor solution

The special feature of the monitoring solution is the monitor developed by Althen with a wide range of dashboard analyses that provide information on the condition of the system and possible maintenance intervals. The structure of the dashboards can be customised, e.g. at system, building and site level or even across companies and countries. Alarm messages are sent by email when the desired limit values are defined. This means that system components can be checked and maintained at an early stage. The IoT monitor offers the option of limit value monitoring in accordance with ISO-10816 as well as the measurement of individual machine data. Depending on the scope of the booking, the measurement solution includes the basic functions mentioned or, in the "Pro" version, FFT visualisations and detailed diagnostic functions in the "Intelligent" package, for example. These include, for example, the detection of unbalance or angular misalignments or malfunctions in roller and ball bearings.

Simple integration into existing systems

Althen's condition monitoring system is easy to integrate for medium-sized and smaller companies with existing systems. Thanks to wireless communication, the solution is not cable-bound, which significantly reduces installation work and therefore costs. Thanks to bidirectional communication, the measuring nodes not only transmit the recorded data, but can also be configured for specific systems from the IoT monitor.