Laser triangulation sensors and IMU

Althen supports our development by providing multiple high-precision sensors. Delft Hyperloop use Althen’s laser triangulation sensors to measure the distance between the pod and the track. Additionally, we integrate ASC’s inertial measurement unit (IMU), also supplied by Althen. These components are critical for achieving stable levitation and precise motor control, with minimal delay.

Reliable measurement in a high-EMI Environment

Our system relies on laser triangulation sensors and an IMU for accurate measurement and control. A major challenge was transitioning from analog to digital output for the triangulation sensors. The switch became necessary due to high electromagnetic interference (EMI) in our setup, which compromised the analog signal integrity. Although the redesign required significant system changes, the transition was smooth. Performance of the digital version is comparable to the previous analog setup.

Sub-millimeter accuracy and fast data response

To maintain a stable levitation system, our offset sensors must deliver sub-millimeter accuracy. The pod’s air gap—the distance to the track—ranges between just 3 and 20 mm, meaning that every decimal matters. The selected sensors must reliably operate within this range, regardless of the measurement principle, as long as they offer high speed, accuracy, and reliability. So far, laser triangulation sensors have fully met these demands.

The IMU also plays a dual role: it supports levitation control and helps validate simulation models by measuring force. This requires the sensor to be both fast and highly sensitive, while supporting a broad measurement range to handle forces of varying magnitudes.

Smart sensor integration and transition to digital data transmission

- The 16 offset sensors are installed around the pod using custom 3D-printed brackets attached to the chassis.

- These connect to a custom-designed PCB via RS485, and all sensor data is routed via CAN bus to the levitation controller.

- Previously, we used analog output with a simple PCB that collected all data lines into one connector. This connected to ADCs in the levitation controller, but EMI issues compromised reliability.

Optimizing high-speed data architecture

- Transitioning to digital output meant rethinking our system’s data handling.

- Each of the 16 sensors transmits data at a minimum of 1.5 kHz (ideally 2 kHz), at 4 bytes per measurement—equaling approx. 50 kb/s per sensor or 750 kb/s in total.

- We first considered connecting all sensors to a single RS485 bus, but bandwidth and identification limitations made this unfeasible.

- Instead, we designed a dedicated RS485 bus per sensor. All buses merge into one central PCB that processes and transmits the combined data over CAN to the levitation controller.

We are proud to have Althen as a long-term partner in our project. Their sensor solutions have proven so reliable that we can rule them out as a source of error during troubleshooting, which significantly speeds up our development process.

Testing and performance tuning

- After building the PCB, we conducted isolated lab tests to validate the RS485 communication and sensor integration.

- We explored sensor data structures and parameter settings, confirming the digital interface was a valuable upgrade.

- Initial tests revealed a ~3 ms delay—too high for our 750 µs control loop.

- By adjusting sensor settings like exposure time and buffer size, we reduced latency to below 750 µs, achieving delay parity with the analog version.

- These optimizations, supported by Althen’s detailed documentation and interface tools, were crucial for successful implementation.

-

AccuracyThe final system delivers an impressive 0.01 mm measurement precision.

-

LatencyLatency is minimal and now matches or even outperforms the previous analog setup.

-

No issuesNo accuracy issues or deviations have been detected, confirming that all expectations for performance and reliability have been met.

Precision and performance validated in a real-world demo

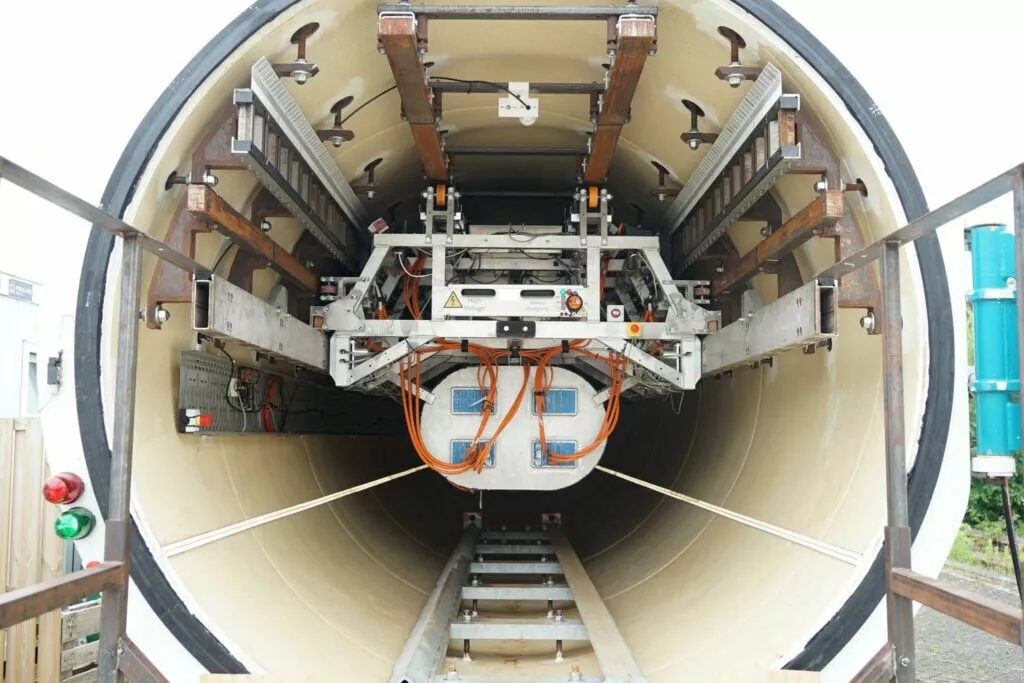

In July 2025, this translated into real-world success: our team became the first student team in the world to give a live Hyperloop demonstration on the 420-meter test track at the European Hyperloop Center (EHC) in Veendam—the longest Hyperloop test track in Europe. This world-first demonstration marked a historic milestone in sustainable transportation innovation. Thanks to the performance of our pod and the reliability of our sensor system, we proudly won the overall prize at the European Hyperloop Week (EHW)—a recognition of both technical excellence and system readiness under live conditions.

Products used in this project

FDRF603 Series Laser Triangulation Sensor

- Measuring ranges: from 2 mm to 1.250 mm

- Universal for many applications

- 0,02% of the range/°С temperature drift

ASC IMU 8.X.Y Tactical grade inertial measurement unit

- Tactical grade IMU with 6 DOF

- FOG-like performance, ARW <0.01 °/√hr

- Modular accelerometer and gyroscope ranges

Althen as a trusted partner in innovation

Beyond product quality, Althen also excels in service and support. Last year, they quickly repaired two damaged sensors, which now perform like new. Their responsiveness and expertise make them an indispensable part of our success—not just this year, but for years to come.

Please contact us

for your project or more information on laser triangulation sensors and IMU's