The challenge

To get the hydrogen car allowed on public roads and meet all 1301 requirements set by the RDW, extra emphasis is being placed on safety this year. Think number plate, mirrors, bigger windows, more lights etc. That efficiency needs not be lost as a result of safety, the team wants to prove by making a world record attempt. Then the Eco-Runner Team Delft will cover 2.056 kilometres on 1.45 kilograms of hydrogen. This will take place on the route of the infamous Elfstedentocht, which they will cover in ten consecutive rounds, day and night for three days. In this way, Eco-Runner wants to demonstrate that there is still much to gain compared to current industry standards and promote a sustainable future.

Eco-Runner Team Delft uses various sensors from Althen in the car itself, and the test equipment. For instance, force sensors in the brake pedal to control the brake lights, pressure sensors in the braking system to detect pressure loss, and a rotating torque sensor is used to determine and optimise the efficiency of the driveline.

The downside of mass-produced parts

The biggest challenge with many parts from the automotive industry is the application to a prototype. Mass-produced parts for a system often exist, but these products are often too large, heavy or unnecessarily elaborate for the Eco-Runner application. In other cases, these parts only work with existing systems and raw data cannot be read, for example. This is where Althen offers solutions with accurate and specialized sensors. Here, the sensors are at the same time still fundamental enough to apply flexibly to a custom-made system.

Rotating torque sensor to optimize efficiency

With the rotating torque sensor, we can measure on a test bench the mechanical work that our engine provides. When this is coupled with the electronic power we can measure at various points in the powertrain, we can determine and optimize efficiency. This is not accurate, repeatable or practically possible with test track driving. Because the sensor can be applied to our full possible range with a torque range of -50 to +50 Nm and a rotational speed of 0 to 650 RPM, we can still simulate any load scenario.

Since these optimizations often involve even fractions of percent, high accuracy of the measuring equipment is very important. Here it is also important that the data can be easily monitored and exported as possible with the TorqView6 software.

Weighing and pressure sensors for braking

The RDW expects a warning light to come on when there is too little pressure in the brake lines at a certain force on the brake pedal, as this may indicate a leak and loss of brake fluid. To measure this, we use a weight sensor in the brake pedal and two pressure sensors at the two separate circuits of the front and rear brakes. Using statics, we can predict what pressure should occur in the circuits at a given brake force and in this way a potential leak can be detected. When the measured pressure is lower than the pressure expected with the measured force on the brake pedal, the warning light will come on.

Products

Which sensors were used for this project?

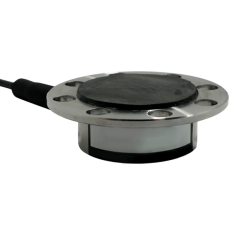

ORT 230/240 Rotating Torque Sensor

- Measuring range: 0,02 to 100 Nm

- Low inertia – High Speed capability

- Non contact/brushless measurement

ALF304 Brake Pedal Force Sensor

- Measuring range: 0 to 2,5 kN

- Measures brake pedal application forces

- Allows attachment to any shape pedal

AGS4000 Standard Pressure Transducer

- Measuring range: 0-500 mbar to 0-700 bar

- With bonded strain gauge technology

- 0.4% Accuracy & ±2 % FS Total Error Band

How the torque sensor is used

The torque sensor is mounted in the center of the test bench between two electric motors. The efficient motor of the car to be tested, and a second motor to serve as a mechanical load to simulate different driving conditions. Over the years, various reducers have been produced to allow the bolt pattern of the flange on the sensor to be fitted to the various electric motors. The sensor has also been mounted directly to the spokes of the rim to test in-wheel motors. Here the flexible couplings between the two sides are important to accommodate any production deviations or deviations from rotational balance. Data is exported and power for the sensor is provided via the digital output with the corresponding adapter cable. Thus, data can be easily read and logged via USB and TorqView6 software.

Brake pedal and circuits

The weighing sensor has two mounting surfaces, on one of these is a plate mounted on which the force is applied with the foot. On the other surface is a part attached to the shaft around which the entire pedal pivots. The two pressure sensors are attached to the two separate brake circuits, so the pressure can be measured separately for both circuits.

In our experience, working with Althen is valuable and enjoyable. We have also heard this same experience from several Eco-Runner alumni. For example, it is very noticeable that Althen is involved in our project and helps with enthusiasm whenever possible. We can always ask questions and are helped well. Also, there is always quick delivery of parts and we get valuable help in finding the right products for a particular application.

Results for Eco-Runner

The efficiency of the driveline has been tested and optimized with an Althen rotating torque sensor for years. Thanks to these tests, the team has achieved several great achievements. For example, Eco-Runner team Delft managed to win the Eco Marathon in recent years, where optimizing our the engine on the test bench was essential for high efficiency. In addition, Eco-Runner has set a Guinness world record where the extensive testing and measurements were indispensable to be able to drive non-stop for three days.

Furthermore, later this year Eco-Runner hopes to have a fully RDW certified braking system in Eco XIV, which uses various Althen sensors to detect abnormalities in the operation. This certification will substantiate the reliable operation and easy integration of the sensors.

Share your challenge

and let us know how we can help you with integrated sensor solutions or sponsorships.