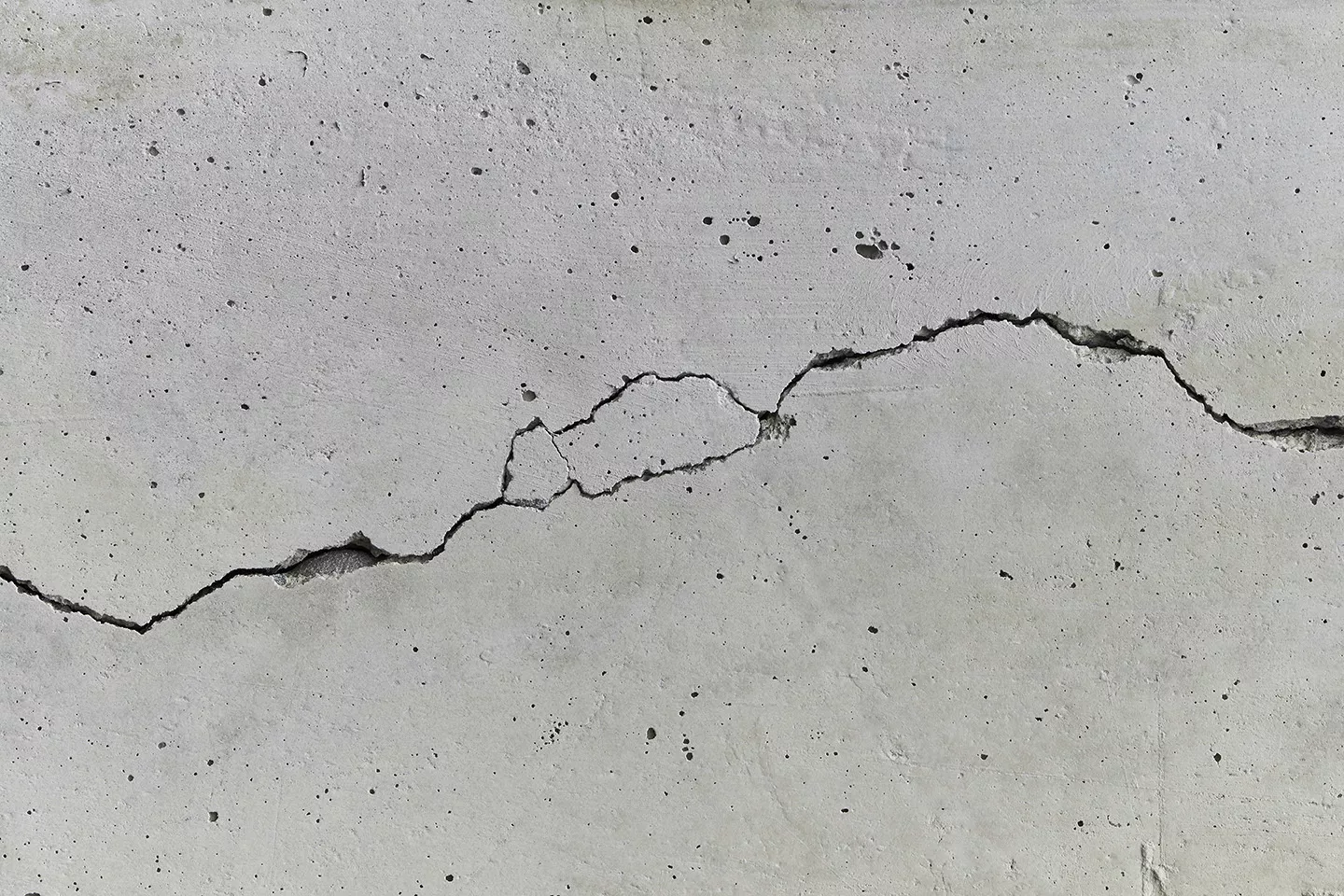

Concrete is a durable and robust material, but it can be weakened over time by environmental influences, loads and material fatigue. Cracks, deformations or material wear can affect the stability of structures such as buildings, bridges or roads. Without systematic monitoring, such damage can go unnoticed, which can lead to serious consequential damage. With the help of strain and displacement transducers, the load-bearing capacity of infrastructural structures can be checked as part of condition monitoring, weak points can be detected at an early stage and preventive measures can be taken. Strain can be caused by external forces, ambient temperatures, drying shrinkage or material creep, for example.

Internal stress measurement and measurement of surface elongation

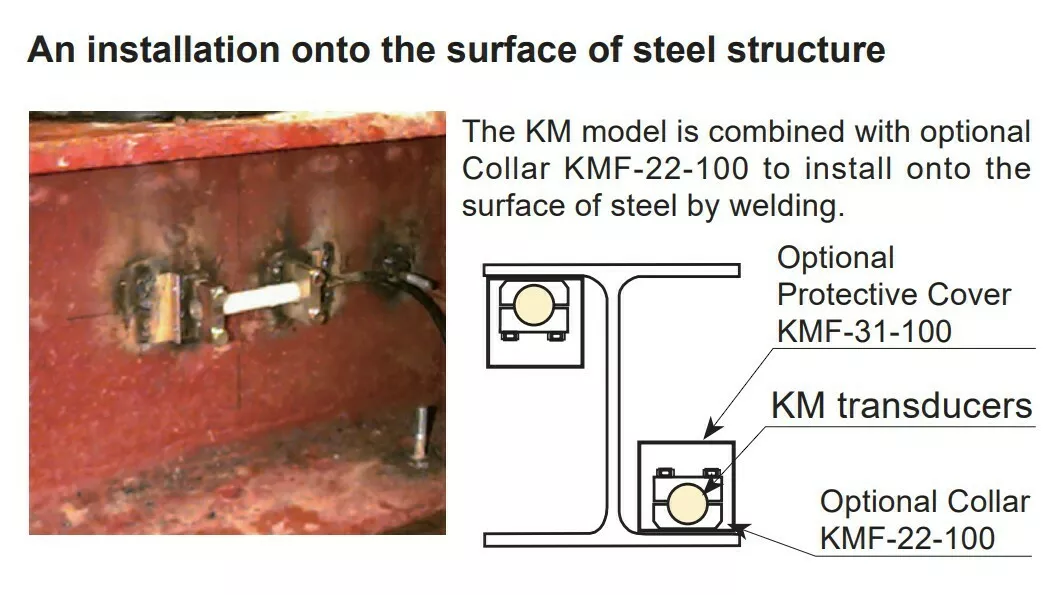

KM strain transducers from our portfolio can be used in two ways to monitor expansion behaviour: Firstly, they can be cast in the concrete itself in new buildings, hardening with it and providing an internal stress measurement in the material. Alternatively, if only temporary measurement campaigns are planned or for existing buildings, KM strain transducers are attached to the surface of concrete or steel beams and detect the surface strain from the outside.

The transducers can be used to determine at which temperature conditions the material expands and how, how heavily it has been loaded over time and how many expansion cycles it has undergone. In comparison with material-specific characteristic values for the respective concrete variant, statements can be made as to how long the concrete will withstand the loads and when maintenance intervals should be scheduled. In the case of a bridge, for example, a total load collective is assumed, which is divided into several sections to be monitored. When a section has reached a predetermined percentage of a load collective, an inspection can be scheduled.

In addition to strain, the built-in thermocouple of the KM-B sensor variant can also detect the temperature within the material.

Whether the KM strain transducers are encapsulated or attached from the outside using accessory clips also depends on whether the sensors are to be reusable or can be integrated in the long term. Internal strain measurement is more precise, but the transducers are also very suitable for external attachment to existing buildings with reliable measured values.

Their advantage over strain gauges, which are often used for strain measurement, is that they are much easier to install - strain gauges have to be applied to selected measuring points using a very precise bonding process - and have a longer service life.

Data acquisition and output

The sensors have a two metre long cable as standard for connection; however, significantly longer versions are also possible. The measured values can be displayed using suitable evaluation electronics or, if necessary, amplified using a measured value amplifier. This is often the case with large structures such as bridges with longer distances.

Checking further materials

In addition to embedding in concrete, the KM strain sensors are also suitable for integration in synthetic resin or fibre-reinforced plastics in order to detect strains and stresses. In the renewable energy sector or in shipbuilding, for example, the sensors can be used to detect material fatigue or deformation at an early stage in order to extend the service life of components and increase operational safety. For components with a thinner layer thickness, the narrowest KM sensor with a diameter of 12 mm may be suitable for moulding. When integrating within the material, care must always be taken to ensure that the material thickness around the sensor is sufficiently large to obtain a valid strain measurement result.

KG-A displacement transducer for crack detection

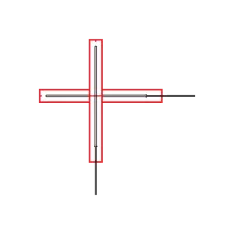

If fine cracks have already formed in concrete, strain measurement is no longer sufficient. With the KG-A displacement transducer, even minimal displacements in the range of +/- 2 to 5 mm can be recorded. This means that the measurement of the KG-A starts where the KM transducers end with the strain measurement: It is placed over a crack and also records a piecewise strain, but also the path of the crack and its potential expansion. Thanks to the monitoring of crack expansion, it is possible to decide when crack size and depth pose a safety risk and countermeasures need to be taken.

The KG-A can also be used to monitor joint changes. Mounted above the joint between two concrete blocks, the transducer can measure a possible displacement of the surface gap. As with the KM expansion transducers, there is also a transducer variant with an integrated thermocouple for simultaneous recording of the material temperature.

Conclusion: Flexible measurement solution for safety-relevant condition monitoring

Infrastructural structures require continuous condition monitoring. With the KM strain transducers and KG-A displacement transducers, loads can be easily determined using strain and stress measurements. The transducers are robust, waterproof and weatherproof, durable and can be installed flexibly, whether embedded in the structure (KM transducers) or attached to the material surface (both transducer variants). Different sizes, cable lengths, connections and additional features (e.g. thermocouple for temperature measurement) enable embedding in a wide range of applications.

Our Services

Matching products

KM strain transducer

- Measurement of curing in materials such as concrete + synthetic resin

- Self temperature compensated strain gauge

- Simultaneous measurement of strain and temperature

KG-A Crack displacement transducer

- Drip-proof structure

- Excellent stability over a long priod of time

- High sensitivity, High accuracy

PLC Series (Polyester Backing) Wire Strain Gauges for Concrete Material

- Strain limit 2% (20000×10⁻⁶ strain)

- Operational temperature: -20~+80°C

- Dual element 0°/90° stacked type