World of Material Testing: Fibre-reinforced Plastics

Strain Gauges for a wide range of applications

Strain Gauges are developed to measure strain on an object. Strain gauges are made of electrical wire or photo edged foil resistance material and are attached to the object. When external force is applied to its structure it creates a physical deformation of the material and creates change in resistance in the attached strain gauges. Strain Gauges are designed to handle every possible application and are often used for research & development, sensor manufacturing and custom made applications.

We offer standard strain gauges but can also help you with a customized desin or a complete measurement solution

The GOBLET series are strain gauges that are characterised by the new shape of the lead to the measuring grid and the use of exclusively lead-free materials in accordance with the RoHS Directive. The GOBLET series is environmentally friendly and has a very long service life. Special connecting wires / cables are also available with lead-free solder.

Strain gauges are the most important component of many transducers. They are used in a wide variety of industries and applications, for example in pressure sensors, force sensors, scales or torque sensors. They can be used, for example, to monitor the safety of infrastructure systems or medical devices or to develop new innovative products. If loads on an object are recognised in good time, high follow-up costs can often be avoided. Strain gauges offer good performance and low acquisition costs compared to other sensors.

A strain gauge operates by utilizing the principle of the electrical resistance change in response to mechanical deformation. It consists of a thin wire or foil grid pattern bonded to the surface of a material. When subjected to strain or stress, the material deforms, causing the strain gauge to also deform. This deformation alters the electrical resistance of the strain gauge, resulting in a measurable change in resistance. By measuring this change, the strain experienced by the material can be determined. This information is crucial for assessing the structural integrity, load distribution, and performance of various objects and systems in engineering and scientific applications.

We have the right strain gauges for every application. We are happy to support you in your selection. At Althen, we draw on more than 45 years of experience to offer you the optimum solution, customised to your requirements. This also includes customised solutions for the application of your strain gauges. We not only supply you with the strain gauges you need, but also support you in the application and training of your employees. Do you have any questions? We are here to help you!

The selection of the right strain gauge depends on the material on which it is to be used. For almost every material - such as metal, concrete, glass, ceramic, wood or even asphalt - there are special designs and carrier materials that fulfil the respective requirements, and the type of attachment depends on the application, the material and the place of use. Strain gauges are often bonded, but they can also be welded to metal support structures and completely embedded in asphalt or concrete.

We offer standard strain sensors and strain gauges but can also help you with a customized design or a complete measurement solution.

The Japanese manufacturer TML (Tokyo Measuring Instruments Laboratory Co., Ltd.) has been producing strain gauges and matching application accessories such as adhesives and masking agents for almost all standard and special applications in Tokyo/Japan for over 60 years. TML's strain gauges are used successfully in a wide range of industries, including automotive production, research & development, construction, shipbuilding and aerospace. The company TML (Tokyo Measuring Instruments Laboratory Co., Ltd.) currently employs around 320 people and relies on strong research and development work as well as a high level of creativity. By observing current trends and the changing needs of customers, the company is constantly developing new technologies and innovations in the field of strain and stress measurement. TML's current programme includes around 8,000 strain gauges in various designs. TML's (Tokyo Measuring Instruments Laboratory Co., Ltd.) expertise in strain gauges is now also reflected in a wide range of strain gauge-based transducers, including load cells and displacement transducers.

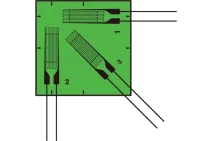

The strain gauges in this series from TML are suitable for all standard applications. They are compliant with the RoHS 2 Directive 2011/65/EU and are supplied with CE labelling. As the GOBLET series, they are available in addition to the conventional strain gauges of the F series. The back is colour-coded to identify the material for intrinsic temperature compensation.

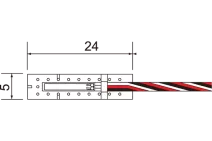

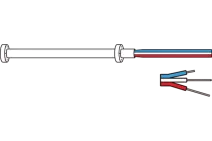

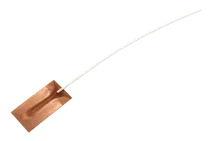

The waterproof strain gauges of the WF series have a pre-installed vinyl lead wire and a complete coating of epoxy resin. The coating is transparent and flexible and ensures easy installation of the strain gauge.

The strain gauges in this series are foil strain gauges with a polyimide resin carrier. Strain gauges for measuring stress concentration or torque are available in this series in addition to the strain gauges for general applications. The GOBLET variants of the QF series are compliant with the RoHS 2 Directive 2011/65/EU and are supplied with CE labelling. Although lead-free solder is used in the GOBLET strain gauges, they perform better than conventional strain gauges due to the use of a unique, special measuring grid.

These strain gauges are designed for measurements at high temperatures up to 300℃. They have a specially developed Ni-Cr alloy foil for the grid and a polyimide resin-coated back.

These strain gauges have a very small grid pattern that is ideal for measuring printed circuit boards and surface-mounted devices. The backing material of the strain gauges is made of polyimide resin. The maximum operating temperature is +300℃ for strain gauges with one measuring grid and +200℃ for measuring devices with two and three measuring grids. The lowest operating temperature is -196℃ for all EF strain gauges.

The CF series strain gauges for cryogenic temperatures use a special plastic for the back and a special alloy for the measuring grid. They enable stable measurement from normal temperature to the cryogenic temperature range. The temperature compensation range is an approximate range.

The high and low temperature strain gauges in the CEF series use polyimide resin as the carrier material and a special alloy for the element. They have a wide operating temperature range from -269 to +200°C.

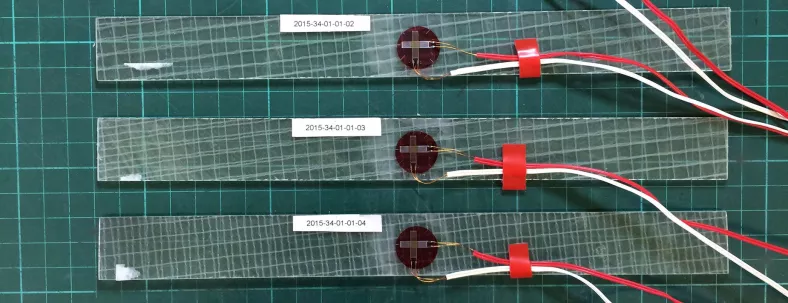

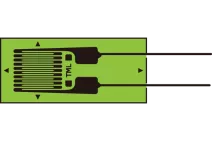

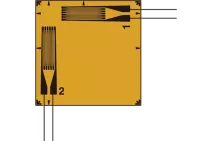

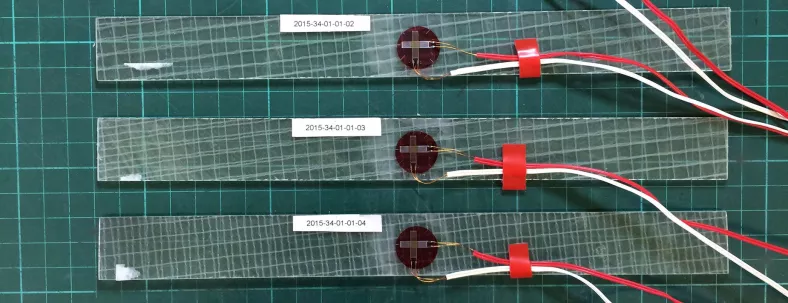

The UBF series are strain gauges that have been developed for measuring composite materials. They are equipped with a special, specially developed grid pattern to reduce the stiffening effect of the strain gauges. By developing the strain gauge base with better compliance, the number of repetitions in temperature cycling tests and the creep properties have been significantly improved compared to conventional strain gauges (comparison by Tokyo Measuring Instruments Laboratory). Specifications for lead-free solder (-F) are also available as an option.

The BF series composite strain gauges are designed for measurement on composite materials and are equipped with a special proprietary grid pattern to reduce the stiffening effect of the strain gauges. Models are available for materials with thermal expansion coefficients of 3 × 10-6/℃, 5 × 10-6/℃、8 × 10-6/℃, enabling use on ceramics, carbon, composites, etc.

These strain gauges are suitable for measuring materials such as plastics, which have a lower modulus of elasticity compared to metals. The specially developed grid pattern reduces the stiffening effect of the strain gauge on the test specimen. This series is available with self-temperature compensation for materials with a coefficient of thermal expansion of 50 or 70 ×10-6 strain/℃.

The LF series strain gauges for wood and plaster are foil measuring strips with a special plastic backing material. The grid pattern is suitable for measuring materials with a low modulus of elasticity and reduces the stiffening effect of the strain gauge on the test specimen. The strain gauges are themselves temperature-compensated for 11×10-6/℃ materials.

These strain gauges have a thin metal backing and are suitable for long-term measurements on wood. Thanks to the metal, the strain gauge is not affected by the moisture contained in the wood. The strain gauges are installed using PS adhesive.

These strain gauges have thin stainless steel backs that prevent the ingress of moisture. This construction is designed for successful strain measurement on concrete surfaces. The WFLM strain gauges also have a moisture-repellent coating and an integrated connecting wire that protects the stainless steel backing. It is intended for long-term measurements or measurements on concrete curing under water.

These strain gauges have strain measuring elements that are fully encapsulated in corrosion-resistant metal tubes (except AW-6). They are suitable for use in various environments, including liquids or gases. They are installed using a special spot welder (W-50R/W-50RB).

The AWM can be used up to a temperature of 300℃ for both static and dynamic measurements. The carrier material is available in Inconel 600 or SUS304 and should be selected according to the material of the test specimen.

The AWMD can be used up to 800°C and is intended for dynamic measurements. The high-pass filter is a standard accessory. The high-pass filter suppresses unnecessary direct current and low-frequency influences (thermal power, drift, etc.). A dynamic strain gauge with DC power supply such as the DC-96A/DC-97A, an intelligent strain recorder such as the DC-204R or a TMR-200 series multi-recorder should be used for the measurement.

The carrier material is available in Inconel 600 or SUS304, which should be selected according to the specimen material. Although it has a half-bridge construction of active and dummy gauges, the measurement is carried out using the full-bridge method using the temperature compensation board supplied. The maximum operating temperature is 600°C for static measurement and 650°C for dynamic measurement.

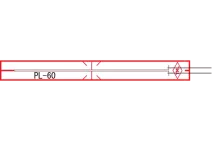

The strain gauges of the P series are strain gauges made of wire with a polyester resin carrier. They are mainly used for measuring surface strains on concrete, mortar or stone.

These are foil strain gauges with a polyester resin carrier material that is identical to that of the P series. They are mainly suitable for strain measurement on concrete or mortar.

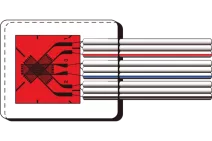

PMF series mould strain gauges are small strain gauges that are embedded in concrete or mortar, e.g. for use in load tests. They can also be embedded in smaller test objects. The carrier material consists of special engineering plastics that ensure water resistance. The temperature-integrated model enables both strain and temperature measurement.

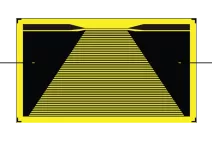

These moulded strain gauges can be embedded in asphalt, e.g. for load tests with roller compaction. A special technical plastic is used as the carrier material, which is characterised by its resistance to water and heat. The strain gauges can withstand high temperatures of up to 200°C during asphalt paving and are temperature-compensated.

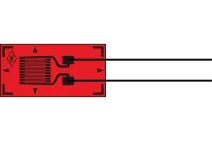

The FAC series crack detectors are used to measure the length and propagation speed of cracks that occur as a result of metal fatigue in machines, ships, aeroplanes and automobiles. A strain gauge is attached in advance to the locations where cracks have occurred or are predicted to occur. As a crack progresses, the measurement grid lines separate one after the other and the output value changes. Use together with the special adapter CGA-120B.

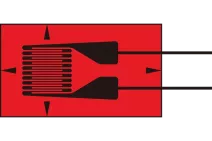

These DM are designed for measuring the stress in any direction of the test specimens in the plane stress field. The measuring devices are sensitive not only in this axial direction, but also in the transverse direction, whereby the sensitivity ratio of the transverse direction to the axial directions is equal to the Poisson's ratio of the specimen material. The measuring devices are also insensitive to shear strain. Accordingly, the output of the gauges is proportional to the stress in the axial direction. The gauges are available in three types, depending on the Poisson's ratio of the sample material.

These strain gauges are used to measure the tensile stress of bolts. They are simply inserted into the pre-drilled hole in the screw using exclusive adhesives. This method is recommended when an ordinary strain gauge cannot be attached to the surface of the bolt. Accurate tension measurement is possible by calibrating the bolt after installing the strain gauges.

These strain gauges are suitable for measuring large strains of up to 10 to 15 %. They also withstand repeated strain in the elastic range (at strain level ±1500 × 10-6 strain), like ordinary strain gauges. However, they are not suitable for measuring repeated strains over a wide range. They are also suitable for strain measurements that are only carried out a few days after the measuring strip has been applied.

These measuring devices have been developed for measuring very large strains of up to 30 to 40 %. They are not suitable for measuring repeated strains in the elastic range or in the large range. They are also suitable for strain measurements that are only carried out a few days after the measuring strip has been applied.

These strain gauges are suitable for measuring large strains of up to 15 to 20 %. They are not suitable for measuring repeated strains in the elastic range. They are also suitable for strain measurements that are only carried out a few days after the measuring strip has been applied.

These measuring devices are glued to the sample surface like normal strain gauges and measure the surface temperature. In combination with the special adapter (TGA), the actual temperature can be measured with these strain gauges.