Laser sensors for the Hyperloop

Optical measurement of paths, distances, positions and profiles

Laser measurement systems are designed for quick and accurate optical measurements of displacement, distances, positions, and profiles. Laser position sensors have high resolutions and operate contact-free in challenging environments. Our laser sensors are used for determining fill levels as well as measuring positions, dimensions, and surfaces. Their measurement ranges lie between 2 and 2500 mm.

We offer standard laser measurement systems, but can also help you with a customised design or a complete measurement solution

This machine is designed for contactless measurement of geometrical parameters for small objects, such as sunflower seeds. The 3D laser scanner FDRF1010SS scans each individual object and identifies its geometry. As a result, you have the parameters of each individual sunflower seed, as well as the total amount.

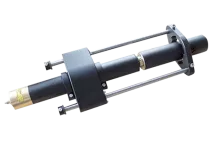

This 3D laser scanning kit can be mounted onto any type of CNC machine. It lets you scan products in order to create 3D computer-simulated models. In the scanning mode, the CNC system moves the sensor across the prototype line by line. This provides an XYZ coordinate array, which is used to create digital model of the prototype.

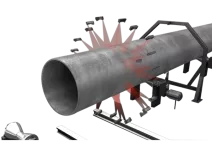

This optical measurement system is designed for contact-free measurement of geometrical parameters such as diameter, roundness, or curvature of large diameter pipes. Its technical characteristics can be adjusted for specific tasks. The system is based on the principle of 3D laser scanning of objects with subsequent generation of a 3D computer model and identification of the geometrical parameters.

We have the right laser measurement system for every application. We are happy to support you in your selection. At Althen, we draw on more than 45 years of experience to offer you the optimum solution, customised to your requirements. This also includes customised laser measurement systems as a complete package. The advantage for you is that we are not tied to one manufacturer and can advise you independently. On request, we can customise the measurement system exactly to your needs. Do you have any questions? We are here to help!

We offer standard laser measurement systems but can also help you with a customized design or a complete measurement solution.