For years, we have been a reliable sensor partner for leading manufacturers in the automotive industry. In this industry, the strictest quality standards apply, including integrity, performance and reliability.

Extensive testing is an essential part of the development process to ensure vehicle safety. These include measurements in the areas of wear and tear, cable integrity, crash behavior and braking performance. Here, sensors provide accurate, reproducible data that is indispensable for optimizing safety systems and vehicle performance.

Sensors for the Automotive Industry

In the rapidly evolving landscape of the automotive industry, sensors play a crucial role in optimizing vehicle performance, safety and overall user experience. Althen Sensors & Controls offers a wide range of sensors tailored to the specific requirements of the automotive industry. Our sensors are used in various critical areas. As an experienced partner for sensor and measurement technology in the automotive industry, we offer customized solutions - accurate, efficient and reliable.

In the automotive industry, safety standards are particularly high. Wear parts such as cables and brakes must be constantly monitored, and crash tests provide information about the behavior of the vehicle, occupants or cargo in various crash situations. The effects are recorded by numerous sensors and the data obtained are used, for example, to improve vehicle and pedestrian protection or to simulate an accident situation. Euro NCAP is a widespread, manufacturer-independent crash test program in Europe.

Althen offers a wide range of miniaturized accelerometers that are fully compliant with Euro NCAP standards. In addition to this certification, the components are also approved for use in crash tests according to international standards such as SAE J211/J2570, ISO 6487 and World SID.In addition, we provide high-precision sensors for monitoring critical engine parameters. These directly contribute to higher fuel efficiency, lower emissions and better overall engine performance.

At Althen Sensors & Controls, we don't just supply sensors - we actually help our automotive customers move forward, with measurement solutions that ensure reliability, innovation and a competitive advantage in a demanding market.

Practical applications for automotive

Control of mounting forces and spring force measurements

Ring load cells, also called donut ring force sensors, are designed to measure forces applied through the center of the sensor. They are ideal for applications that require a cable, shaft or bolt to pass through the center of the sensor.

These load cells are used for such purposes as checking preload in bolted joints, measuring mounting forces, and recording forces in shock absorbers or springs. Their compact, symmetrical design makes them particularly suitable for integration into tight or existing structures.

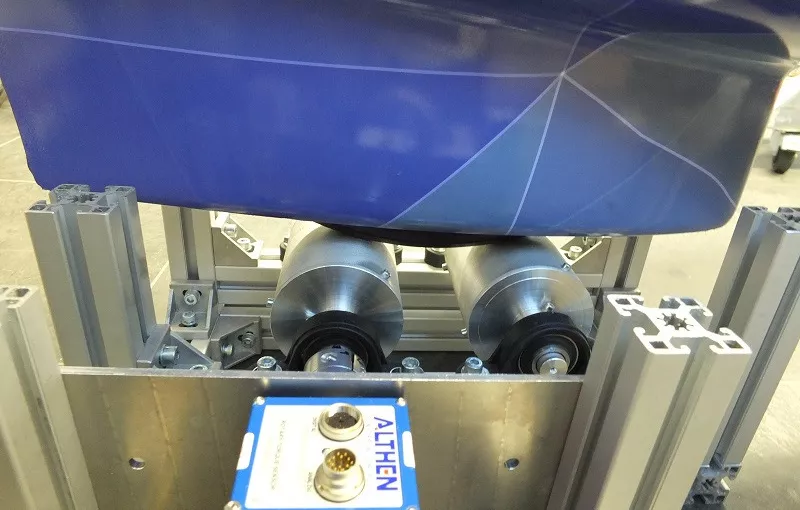

Measurement systems for crash tests and chassis tests.

Pancake load cells are distinguished by their extremely flat design, resulting in a very low installation height. They were developed specifically for measuring high compressive forces and are frequently used in demanding test environments within the automotive industry.

In crash test measurement systems, these sensors measure forces that occur on vehicle structures or crash test dummies during impact tests. In addition, they are used in chassis tests and wheel force measurements, where they record vertical forces on the wheel during dynamic test bench tests or road test runs.

Thanks to their robust and flat construction, pancake load cells are ideal for applications where accurate force measurement is required but available installation space is limited.

Chassis analysis and steering behavior

Multi-axis force sensors (2D/3D force measurement) record forces in multiple directions simultaneously (e.g. X, Y, Z) - ideal for complex load situations. Typical applications include chassis and axle geometry analyses, measuring combined forces and torques on wishbones, wheel suspensions or steering components. They are also often used for steering behavior or haptic testing.

Oil pressure monitoring and brake pressure measurement

Pressure sensors and precision pressure sensors detect the pressure of fluids or gases in hydraulic or pneumatic systems. They are used to monitor oil pressure and fuel pressure and contribute to safe engine lubrication and fuel injection.

In ABS and ESP systems, they monitor and control brake pressure to ensure vehicle safety.

Stability systems and navigation applications

Our gyroscope sensors (angular speed sensors) measure angular velocities - essential data for position and motion control. They are often used in driving stability systems (such as ESC and ESP) to detect vehicle rotation to control braking and drive torques.

In the area of navigation and autonomous driving, inertial navigation supports systems such as GPS and camera/radar systems in determining vehicle position and lane keeping.

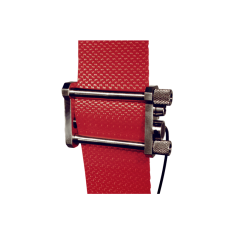

Force measurement at pedals and seat belts

Pedal force measurement sensors record the force the driver applies to the brake or accelerator pedal. They provide valuable data for analyzing the driving experience and developing driver assistance systems.

Seat belt force sensors measure the traction force in the seat belt - a critical parameter for evaluating safety impact and occupant safety.

-

Extensive knowledgeMore than 75 years of experience in the measurement and sensor technology sector

-

High-quality sensor solutionsAlways up-to-date: technology and knowledge

-

Customized measurement solutionsTailored to your needs

-

In-house R&D and design departmentIn-house development and production

Product categories

(Ultra high) precision pressure sensors

- Measuring range 0 to 5.000 bar

- Accuracy from 0.75% to ≤ 0.01%

- Wide range operating temperatures

Multi axis vibration sensors

- Measuring range 12 g to 6.000 g

- Low noise & great frequency response

- Measure vibration in two or more axes

Special automotive force sensors

- Measuring range 100 N to 50 kN

- Designed for test & measurement

- Perfect for automotive industries

Automotive testing accelerometers

- Measuring range ±25 g to ±10.000 g

- Various measurement axis available

Custom special application load cells

- Customized measuring ranges

- Wire rope measurements

- Pedal force measurements

Our clients

Customized sensor technology for the automotive industry

In the dynamic world of the automotive industry, there is no one-size-fits-all solution for every application. That's why Althen Sensors & Controls relies on customer-specific sensor technology, tailored to the unique challenges and requirements of each application.

In addition to a broad portfolio of proven standard solutions, we also develop custom sensors that can be seamlessly integrated into existing systems - whether for special measurement requirements or incorporation into complex niche systems. Our team of experts works closely with your engineers to realize high-quality and application-oriented solutions.

Our goal is to provide sensors that adapt flexibly to the technical specifications of your vehicle platform - resulting in maximum efficiency, reliability and performance. This includes precise sensors for engine monitoring that contribute to higher fuel efficiency, lower emissions and optimized engine dynamics.

At Althen Sensors & Controls, we provide more than just sensors: we offer you a technological advantage in a highly competitive market.

Reliable sensor technology for the automotive industry

- Pressure sensors are used in various systems within the automotive industry, such as engine control, tire pressure monitoring systems (TPMS) and braking systems. Tire pressure monitoring systems (TPMS), braking systems. Accurate measurement of pressure fluctuations, for example, is important for optimizing engine performance and ensuring safe braking.

- Temperature sensors are used for monitoring engine temperature and in air conditioning systems, among other things.Accurate temperature measurements prevent overheating of the engine and contribute to reliable operation of the cooling system. At the same time, they ensure a constant and comfortable temperature in the interior, which significantly increases driving comfort.

- Position sensors are used to detect, among other things, the position of the throttle valve and the position of the transmission. Important for precise control of engine functions and exact positioning of various vehicle components.

- Accelerometers and gyroscopes are used for vehicle stability control and the detection of rollover movements. Accelerations and rotational speeds are important for advanced safety systems and vehicle stability.

Important factors in choosing automotive sensors

- Accuracy and Precision

Make sure the sensor meets the necessary accuracy and precision requirements for your specific application. Even small deviations can significantly affect vehicle performance and system reliability. - Environmental factors

Consider typical operating conditions such as temperature, humidity, dust or chemical influences. The sensor should be designed to perform reliably under these conditions over the long term. - Energy Efficiency

Ensure low energy consumption,especially in applications where energy efficiency has a direct impact on overall vehicle performance and fuel consumption. - System Compatibility

Choose sensors that can be easily integrated into existing vehicle systems and electronic components. A high level of integration reduces development effort and reduces costs. - Durability and reliability

Automotive sensors must be mechanically robust and reliable. They must withstand vibration, temperature fluctuations and other long-term stresses. - Meets standards and guidelines

Ensure that sensors comply with relevant industry and safety standards.

Compliance with regulatory requirements increases product safety and also increases the likelihood of market acceptance. - Cost efficiency

Strive for the right balance between performance, quality and cost. The chosen sensor should perfectly match the application requirements without unnecessarily burdening the budget.

Our projects

View our projects & applicationsMatching products

SGR520/521/522 Advanced Digital Rotary Torque Transducer

- Torque range: 0 - 13000 Nm

- Accuracy: ±1rpm up to 30,000 rpm

- Temperature accuracy: ±1 °C

ALF305 Seat Belt Tension Force Sensor

- Measuring range: 0 to 16 kN

- Measures seat belt tension forces

- Minimal mass, stress and deflection

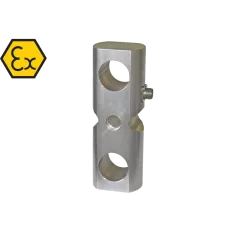

TBT Loadlink (ATEX Certified)

- Measuring range: 0 - 30 to 0 - 250 ton

- Holes for shackles linkage

- Combined error ≤± 0.08%

ALF322 Accelerator Pedal Force Sensor

- Measuring range: 0 to 250 N

- Off center loading compensation

- Lightweight aluminium alloy construction

TLB Profi Digital Amplifier

- Six-digit semialphanumeric display (height 8 mm), 7 segment LED

- Four buttons

- Dimensions: 25 x 115 x 120 mm

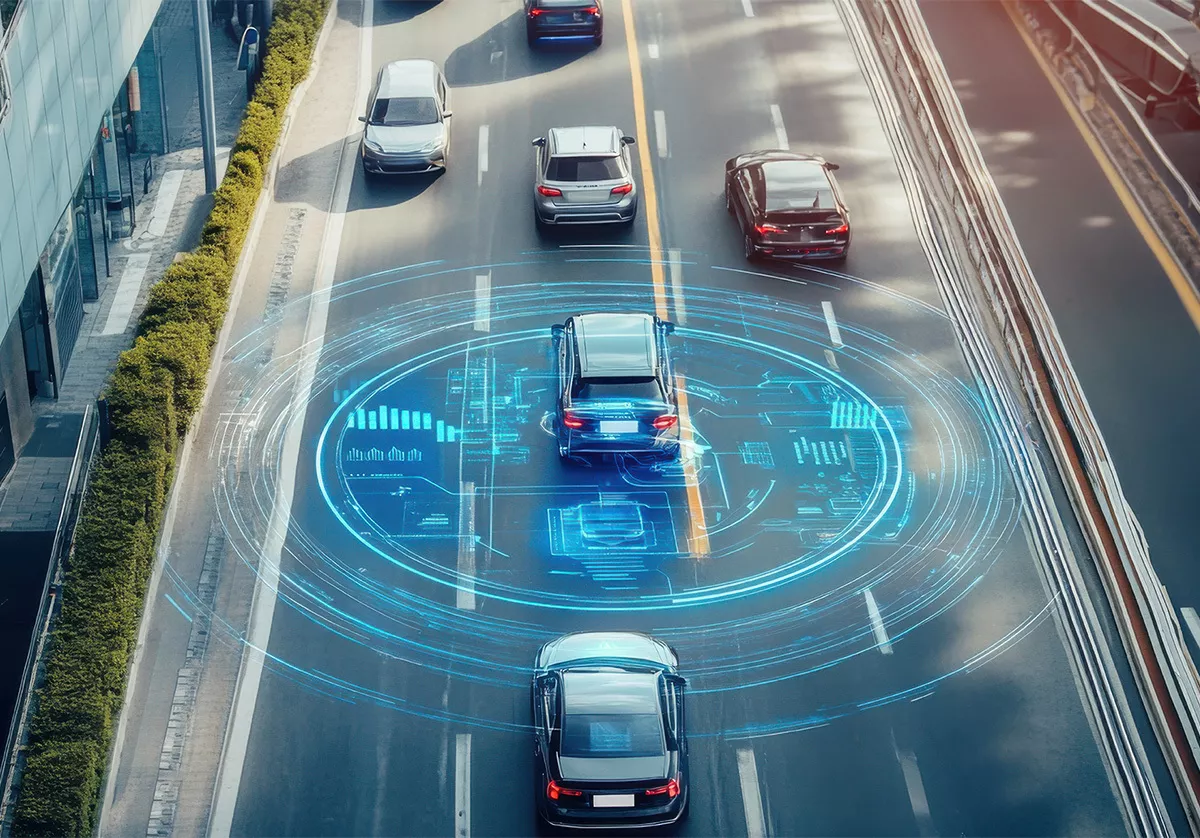

Sensor technology for vehicles: the road to tomorrow's mobility

The future of automotive sensor technology is on the brink of a profound transformation. Innovations in this field will fundamentally change the way vehicles operate, increase safety and enable a smarter, more efficient driving experience. Sensors play a key role in this. They are at the heart of technological advances toward autonomous driving. As the development of self-driving vehicles continues at a rapid pace, the importance of advanced sensor solutions is growing.

These systems make it possible to accurately perceive the environment, predictively analyze complex situations and react immediately. Thus, they lay the foundation for safe, intelligent and self-determining vehicles of tomorrow.

The increasing demand for sustainability and energy efficiency is accelerating the development of innovative sensor technology. Sensors are indispensable for optimizing fuel consumption, reducing emissions and realizing environmentally friendly mobility solutions. In addition, sensors play a central role in vehicle safety. They provide real-time data to modern driver assistance systems and support advanced functions such as collision prevention, pedestrian detection and adaptive cruise control. In doing so, they form the basis for safer, more intelligent and more sustainable driving.

The increasing connectivity of vehicles places new demands on sensor technology. Applications such as vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communications require sensors that enable seamless interaction between the vehicle and its environment.

Therefore, automotive sensor technology is developing into one of the key areas of innovation within the mobility of the future - intelligent, safe, connected and sustainable.