Sensors and measurement solutions for the rail industry, rail technology and rail vehicle technology

At Althen you will find a wide range of innovative measurement systems for trains, streetcars and subways. From compact flush-mounted sensors to complete measurement solutions for maintenance departments. We develop our systems in close cooperation with customers and partners from the rail industry.

Our measurement systems are based on advanced laser measurement technology and make it possible to measure both rails and wheels quickly and accurately. Thanks to this efficient technology, measurement results are delivered within seconds. This is ideal for use in demanding maintenance and inspection environments.

Measurement systems for safe and efficient rail transport

Our rail measurement systems are designed to improve the safety, reliability and operational efficiency of rail operators. Among other things, they offer dynamic and static weighing solutions for accurate measurement of axle loads and wheel loads. With these systems, operators gain access to actionable data to:

- Optimize maintenance strategies

- Improve vehicle load distribution

- Reduce wear on track and equipment

In addition, we offer solutions for:

- Direction and speed detection of trains

- Vibration monitoring

- Temperature monitoring in braking systems

These technologies contribute to safe, predictable and cost-conscious operation of rail vehicles and infrastructure.

Applications in the rail industry

Derailment protection

Train derailments can be caused by running gear defects, moving loads or dynamic effects between track and vehicle. Even small deviations in these parameters must be detected reliably and in a timely manner to enable preventive maintenance.

Using Inertial systems (IMU), force sensors and capacitive accelerometers, maintenance teams obtain actionable data to identify risks, make diagnoses and make targeted repairs before critical situations arise.

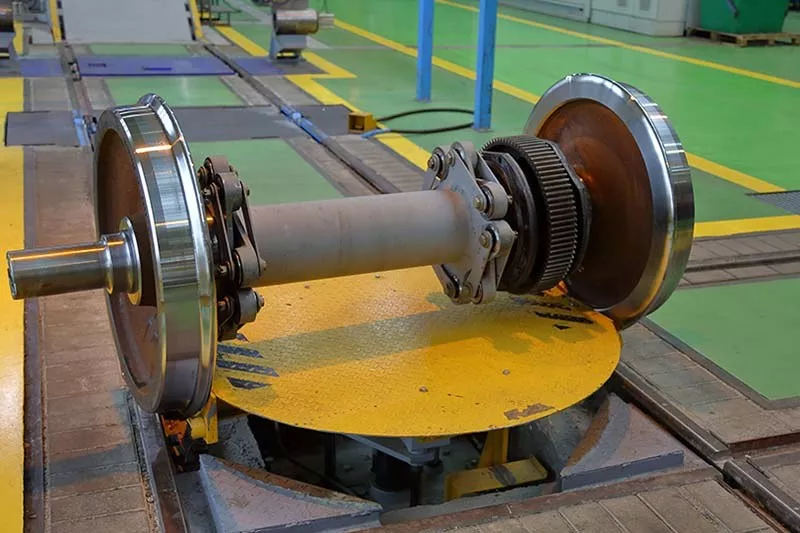

Wheel diagnosis: flat spot detection

Wheel defects, such as flat spots or oval formation, can lead to increased wear on the wheel set and rails and in the worst case, to derailment. Regular monitoring is therefore essential. Using accelerometers, wheel pressure sensors, geometry measurement systems or automated 3D wheel measurement systems, damage can be detected early. This is possible quickly, efficiently, even while driving on open track.

Weight detection

Exact weight determination of locomotives and wagons is essential. It prevents infrastructure overload and supports the calculation of user charges. It also provides important safety information, for example when cargo shifts during travel. Our Wireless Wheel Load Measurement System or Weighing in Motion (AWIM) system make it possible to measure weight quickly and easily. This can be done without interrupting train traffic.

Driving comfort measurement & structural analysis

Not only rail vehicles, but also infrastructure such as bridges, rails, switches and the track bed must be actively monitored. This is essential for a reliable and safe railroad system.

For bridges, the focus is on vibration monitoring, while the track bed is analyzed for vibration and structural changes. Multi-axis vibration sensors and acceleration sensors accurately record the required measurement data here.

Smart maintenance

Wheels of trains and streetcars wear continuously. This affects wheel parameters such as diameter, flange height and spacing. For efficient maintenance planning, it is important that these data are already known before arrival at the depot. An effective solution is the fast and non-contact measurement of wheels with dynamic 3D Wheel Measurement System, directly while driving. This provides the maintenance team with the correct data in a timely manner.

Mobile measurement solutions

Our measuring devices provide reliable and accurate data on wheel parameters. They are based on non-contact laser technology and specially developed for use at maintenance sites in the railroad industry. The system innovatively measures diameter, center distance and wheel profile. All measurement data are automatically collected and stored via Bluetooth. The data can be easily exported to other systems for further processing or reporting. Read more about railway measurement systems.

-

A-Class QualityIn product and process

-

Long-term PartnershipsWith all stakeholders

-

Reliable and ExperiencedProven trackrecord over 75 years

-

Innovative and NewState-of-the-art products and developments

Product categories

Automated 3D wheel measurement systems

- For full 3D modelling of railway wheels

- Measuring speed 15 km/h to 350 km/h

- Accuracy to 0.05 mm

Train/Tram weighing systems

- Variable measuring ranges available

- For accurate static and dynamic weighing

- Determine balance of every individual axle

Back-to-Back measurement tool

- Various measuring ranges available

- Measurement of back-to-back distance between wheels

Wheel diameter measurement tools

- Measuring range 400 to 1.400mm

- high precision measuring of wheel rolling circle diameter

Disk brake profile measurement tool

- Measuring range to 30 mm

- Analyse disk wear and brake disks profile

- 100.000 measurements memory capacity

Rail profile measurement tools

- Measuring range -15,00 to +20,0mm

- Analyze rail head profile and rail wear parameters

Wheel profile measurement tool

- Measuring range 1 mm to 965 mm

- Measure up to 17 geometric parameters

Capacitive accelerometers

- Measuring range: up to ±400 g

- Resolution: up to <1 µg

- Excellent temperature stability

Our clients

Special measurement solutions

We offer a range of specialized measurement solutions tailored to the high demands of the rail industry. One of the highlights is the wireless wheel load measurement system, which performs static and dynamic load measurements, contributing to safety and operational efficiency.

The In-Motion Weighing System - Weighing in Motion (AWIM) provides real-time information on axle loads and wheel conditions, including wheel damage and overload detection. This supports proactive maintenance and risk assessment in the event of derailments. In addition, our vibration and temperature sensors provide valuable insights into the structural condition of rail vehicles. They increase reliability even under harsh conditions.

All our systems are designed for robust use and provide accurate and reliable measurement data necessary for a safe and efficient railroad network.

Accept the marketing cookies to view this video.

Click here to change your consent.

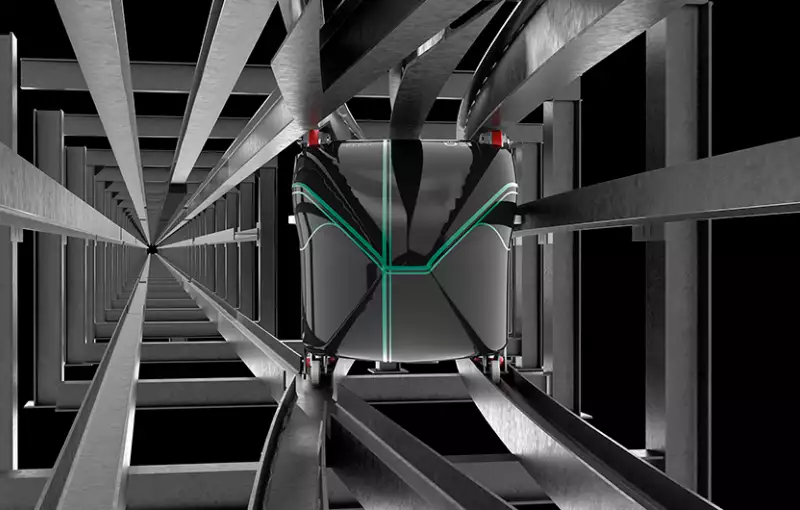

Weighing in Motion System (AWIM)

The Weighing in Motion System is a stationary measuring system designed as a dynamic scale. It is used for in-motion weighing, wheel fault detection, and train identification. By combining multiple measurements, the system achieves an overall accuracy better than ±0.5% – even at varying speeds. This complies with OIML R106, class 0.5.

Integrated Vehicle Identification

The system includes an integrated algorithm that identifies locomotives and wagons based on the distance between wheels and bogies. For enhanced identification, additional features can be added, such as:

- Vision cameras for automatic registration of vehicle numbers and axle identification

- An integrated RFID scanning system

These features improve traceability and support accurate data linkage to individual vehicles.

Accept the marketing cookies to view this video.

Click here to change your consent.

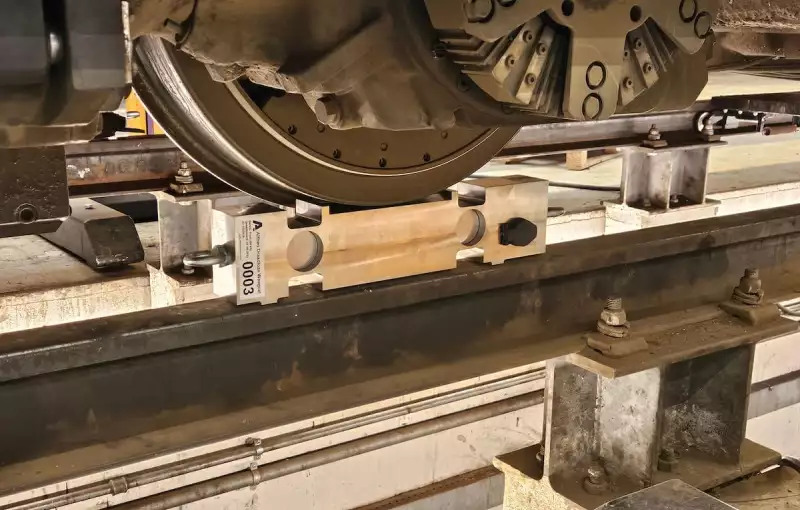

Wireless wheel load measuring system

This intelligent wireless weighing system enables fast and accurate wheel measurements within seconds. Each specially designed load cell is equipped with a wireless module that transmits the measurement data directly to dedicated software on a laptop. The software provides a clear overview of axle balance and automatically calculates key parameters such as axle load, bogie load, and the total weight of the vehicle.

The system is customisable to customer-specific requirements and streamlines weighing and balancing processes to ensure optimal performance and safety during maintenance operations.

Precision measurement instruments

Precision measuring tools for railway maintenance and quality assurance:

Our precision tools support accurate inspection and maintenance of rail vehicles and infrastructure. They help detect wear early, ensure consistent performance, and maintain safety standards.

Wheel diameter gauges provide accurate diameter measurements to detect wear and ensure consistent wheel performance.

Wheel profile measurement tools are essential for assessing wheel shape and detecting early signs of wear that may affect track interaction and safety.

Back-to-Back measurement tools measure the distance between wheels – a critical factor for proper alignment and rail stability.

Disc brake profile measurement tools monitor brake wear and help maintain braking performance and compliance with safety standards.

Rail profile measurement tools measure rail shape and wear, supporting regular track maintenance for smooth and safe railway operation.

Calibration of railway measuring equipment

Althen offers specialised calibration services to ensure the accuracy of railway measuring instruments. Our calibration of track gauge measurement tools guarantees that each device meets strict accuracy standards and provides reliable data for maintenance and safety inspections.

Regular calibration by our experienced technicians extends the service life of the equipment, minimises measurement deviations, and gives railway operators confidence in their measurement and maintenance processes.

Our projects

Use casesRelated products

ASC 4421MF Capacitive accelerometer

- Lightweight 10 g housing

- IP67 anodized aluminum

- Frequency response up to 7 kHz

FDRF603 Series Laser Triangulation Sensor

- Measuring ranges: from 2 mm to 1.250 mm

- Universal for many applications

- 0,02% of the range/°С temperature drift

ASC IMU 8.X.Y Tactical grade inertial measurement unit

- Tactical grade IMU with 6 DOF

- FOG-like performance, ARW <0.01 °/√hr

- Modular accelerometer and gyroscope ranges

How to choose the right measurement system

From passenger safety to operational performance, reliable sensor solutions are essential in the railway industry. Althen provides tailored measurement systems designed to meet the specific demands and challenges of this sector. When selecting a measurement system, consider the following aspects:

- Environmental resistance Rail and tram systems operate under diverse conditions — from busy urban environments to remote areas. Sensors are exposed to heat, moisture, vibrations, dust and dirt. Althen’s robust sensors are designed to withstand these challenges, ensuring reliable measurements and long service life, even in harsh environments.

- Accuracy and precision Real-time, high-accuracy data is vital for safe and efficient railway and tram operations. Althen sensors measure key parameters such as speed, displacement, pressure and temperature. This enables precise control adjustments and supports predictive maintenance, increasing the reliability of safety and control systems.

- Reliability and durability Rail and tram systems operate continuously and face demanding conditions. Althen supplies durable sensors that deliver stable performance over time, even under high loads, strong vibrations and fluctuating temperatures.

- Integration and compatibility

For seamless implementation, sensors must integrate into existing rail infrastructure. Althen’s solutions support standard communication protocols and interfaces, enabling smooth data exchange between subsystems. This flexibility simplifies retrofitting, future upgrades and scalability as technologies and operational requirements evolve.

Althen Sensors & Controls develops and delivers customised sensor solutions, specifically engineered for the railway industry. We combine technical expertise with in-depth market knowledge to deliver systems that integrate seamlessly into your operations. Our sensors provide high performance and proven reliability, helping you improve safety, efficiency and operational continuity across your rail and tram networks.

Process optimisation, predictive maintenance, digitalisation and IoT in the railway sector

The future presents railway operators, infrastructure managers and maintenance providers with major challenges. How can the growing demand for passenger and freight transport be met in an efficient, reliable and cost-effective way?The key lies in reliable monitoring of infrastructure and vehicle components. By using sensors and monitoring systems, linked to databases and smart data analysis, failures can be reduced and maintenance costs lowered. Althen offers innovative solutions for:

- Predictive maintenance

- Maintenance and service

- Quality assurance

- Repair support