Sensors for the aviation industry

The aviation industry requires high quality, safety and absolute accuracy for its critical applications. At Althen you will find customized solutions for gyroscopes, flow sensors, pressure and acceleration sensors for all your requirements. We supply various sensors that meet the high demands of the aerospace industry.

Gyroscopes (angular velocity sensors)

Where heavy, maintenance-prone mechanical gyroscopes were previously used, our MEMS gyroscope sensors and air data systems now offer a compact, maintenance-free and highly accurate alternative. Thanks to a unique silicone ring technology with no moving parts, in a hermetically sealed ceramic housing, these very small sensors deliver stable performance under a variety of conditions, with high resistance to moisture and temperature.

Air Data Probes

In addition to MEMS gyroscopes, air data probes are also used to measure air data with high accuracy. They provide real-time information on the position of an aircraft or UAV relative to the apparent wind. The probes are heatable, which makes them suitable for use at high altitudes, for example in unmanned aerial vehicles. Over 90% of our air pressure probes are custom developed.

Accelerometer

An accelerometer measures forces such as gravity, motion and vibration, and helps systems better interpret their environment. Althen offers a wide range of accelerometers.

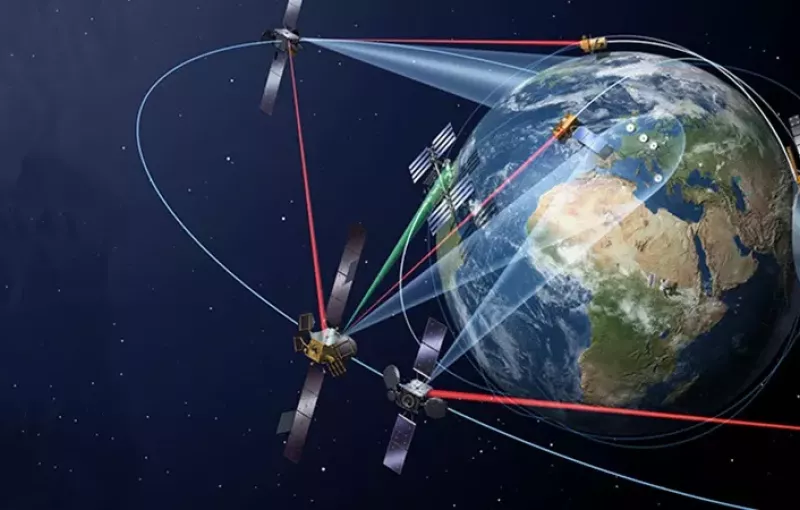

Inertial navigation systems

IMUs (Inertial Measurement Units) are essential in aerospace systems, providing important data on orientation, acceleration and gravity. Our IMUs combine high accuracy, low noise and robust design, making them ideal for navigation, guidance and stabilization in aircraft, satellites and UAVs.

Aerospace applications

Test benches and test setups

Test equipment for hydraulic and pneumatic systems must be compact, lightweight and highly accurate. Space applications often require special threads, as well as a wide measuring range and reliable performance. Althen supplies pressure sensors that perfectly match these requirements.

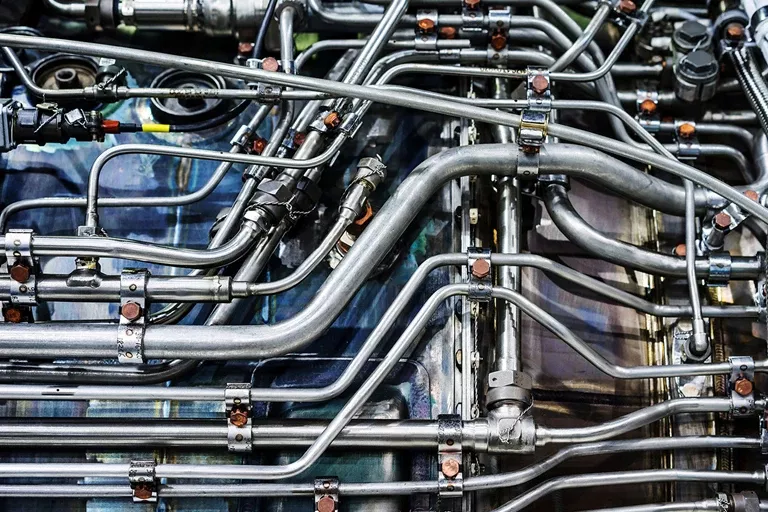

Fuel Systems

The implementation of power transmission systems often requires customized sensor assemblies. These must be able, even under extreme conditions, to perform temperature and pressure measurements accurately and reliably. Althen supplies sensors suitable for safety-critical applications in aircraft construction, where high demands are placed on accuracy and reliability.

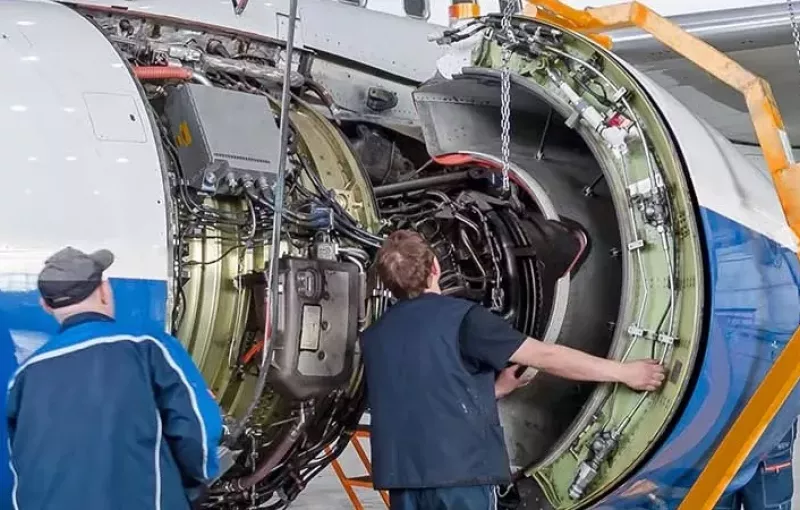

Spare parts and retrofitting

Replacement of discontinued sensors? We think in terms of solutions. Althen supplies suitable sensors, adapters, cables and housings customized to ensure that your aircraft or helicopter remains reliable and operational for a long time even if spare parts are no longer available through the manufacturer.

-

High accuracy and precisionEngineered for critical applications

-

Rugged constructionConsistent performance under harsh aviation conditions

-

Customization capabilitiesCustomized to your aviation application

-

Comprehensive testingTested and certified for aerospace

Product categories

High precision gyroscopes

- Measuring range ±75°/s to ±900°/s

- Excellent accuracy and non-linearity

- Ideal for for aerospace applications

Aeroprobe

- Miro air data computer

- Probes and multi-hole probes

- Various shapes, sizes and geometries

Servo inclinometers

- Measuring range from ±1.0° to ±90.0°

- High accuracy & resolution and low noise

- Robust & sensitive sensing technology

Inertial systems (IMU)

- Measuring range ±75°/s to ±24,000°/s

- Acceleration range ±2 g to ±6.000 g

- Six-degrees-of-freedom (6-DOF) IMU's

LVDT sensors

- Measuring range 0.13 mm to 508 mm

- Excellent linearity & infinite resolution

- High durability and reliability

Eddy current sensors

- Measuring range 0,25 mm to 60 mm

- Non-contacting measurement technology

- Perfect for harsh environment application

Our clients

Advanced technology, reliable support

At Althen, we continuously invest in R&D to integrate the latest sensor technologies. Thus, we offer aerospace customers access to state-of-the-art sensors with advanced features and high reliability. Our support extends throughout the entire process: from sensor selection and system integration to life cycle management. You benefit from technical expertise, solution-oriented support and personal service , exactly when you need it.

This is how to choose the right sensor

The choice requires careful consideration of several factors to ensure optimal performance, reliability and safety. Engineers consider the following aspects, among others:

- Accuracy and precision Aviation systems place high demands on measurement accuracy and reproducibility. Choose sensors with proven precision and low measurement uncertainty to meet the industry's stringent performance requirements.

- Reliability and durability Aerospace environments are often extreme, with exposure to high temperatures, vibration, shock and radiation. Choose sensors with rugged designs that can withstand these conditions to prevent failures and ensure long-term reliability.

- Temperature and pressure ratings Ensure compatibility with operating conditions by selecting sensors based on their temperature and pressure resistance. Choose models that continue to perform within the specified range without loss of accuracy or reliability.

- Size, Weight and Power (SWaP) Space and weight constraints play a starring role in the development of space systems where every gram and centimeter counts. Choose compact, lightweight and power-efficient sensors.

- Response time and frequency range Ensure timely and accurate data acquisition by selecting sensors with fast response time and wide frequency range. This is especially essential in dynamic space environments, where capturing transient events and high-frequency signals is critical.

- Calibration and maintenance Choose sensors that are easy to calibrate and maintain, with accessible procedures and long-term stability. Regular calibration is important to ensure long-term accuracy and reliability.

- Compatibility and integration Choose sensors that integrate easily with existing aviation systems and interfaces. Standard communication protocols and compatible interface options ensure smooth integration and optimal interoperability within the system architecture.

- Cost and life-cycle considerations Consider the total cost of ownership, from acquisition to maintenance and service life. Choose sensors that combine optimal performance and reliability with cost efficiency over the full life cycle of the space system.

A focused consideration of these parameters allows engineers to select sensors that are technically compatible, operate stably and meet system requirements within aerospace applications.

Our projects

Aerospace projects & applicationsAssociated products

KD-5600 Digital Differential Measuring System

- 24-bit high-resolution output

- SPI, analog, or FPGA interface

- Bandwidth up to 60 kHz

E Series LVDT Position Sensor

- Measuring range: 2,54 mm to 50,8

- Magnetically shielded case

- Non-linearity: ±0.5% or ±1%

SGR530/540 Torque Sensor

- Measuring range: 1 to 13.000 Nm

- Large fully functional overrange capability of 250% (SGR 540)

- Minimal side & end load errors

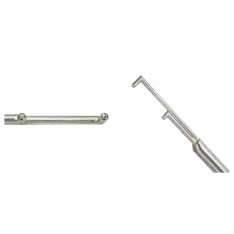

Custom Probes

- On request

- Customization can include tip sizes, geometry, mount, or materials

- Images for examples

Micro Air Data Systems

- Multiple models for different applications

- Reliable and expertly engineered

- Certifications for operating in harsh environments

AWLH-10 HeliNav Loadlink Series

- Measuring range: 0 - 1 to 0 - 10 ton

- Battery life up to 250 hours

- Transmits data at least 100m

Innovations for tomorrow's aviation industry

The development of space technology offers new opportunities for sensors. Innovations in materials science, miniaturization and data analysis will make sensors significantly more sensitive, energy-efficient and resistant to extreme environmental conditions. These advances lay the groundwork for smarter aircraft designs, autonomous navigation and new applications in space exploration - aiming for maximum performance and reliability in the most demanding environments.

Smart sensors

A key driver of innovation is the integration of artificial intelligence (AI) and machine learning into sensor technology. This allows sensors to dynamically adapt to their environment and optimize their performance in real time - a big step toward intelligent, self-learning measurement systems. At Althen Sensors & Controls, we actively contribute to this development. With continuous investment in research and development, we are pushing the boundaries of sensor technology, for an aerospace industry that combines performance, reliability and future-proofing.