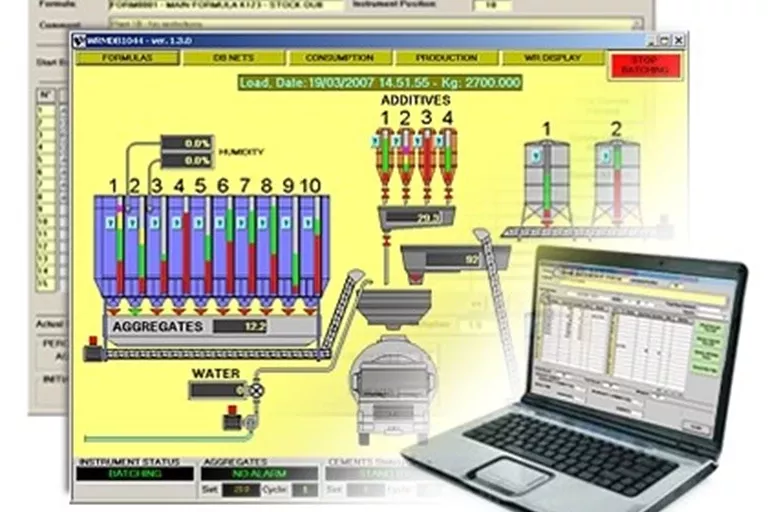

Automate quality control in production

Cost-effective and efficient monitoring of production processes

Bus compatible evaluation electronics for automated applications. Our amplifiers and (digital) indicators for high-tech weighing components have bus interfaces are in accordance with all relevant standards, including OIML, ATEX, IECEx, EAC, NTEP, and UL. The fieldbus interfaces provide versatile connectivity. You also save time, cost, and resources by combining and integrating them with existing systems.

We offer standard digital automation instrumentation, but can also help you with a customised design or a complete measurement solution

For many years, Althen customers have benefited from innovative solutions in the field of digital signal processing, such as regulation and control technology, individually tailored to their specific needs. We offer a comprehensive product portfolio and thus cover the entire range of services - including the connection of sensors to bus systems.

You can also easily combine other sensors and measurement technologies from Althen with our automation technology. This is because they also comply with industry standards such as Profibus, Modbus, CANBus and EtherCAT or already include the bus interface.

We have the right measuring amplifiers and digital displays for every application. We are happy to support you in the selection of measuring amplifiers, digital displays and measurement data acquisition hardware. At Althen, we draw on more than 45 years of experience to offer you the optimum solution, customised to your requirements. This also includes customised solutions for digital signal processing as a complete package. Do you have any questions? We are here to help you!

We offer weighing indicators and digital displays for weighing and dosing technology from Laumas. They ensure accurate and reliable weight measurement in various applications such as system control or food production.

Weighing indicators are devices that are used in conjunction with scales to measure and display the weight of objects or substances. They are an essential component of weighing systems. The main function of a weighing indicator is to record and display the weight placed on the scale. Laumas weighing indicators have additional functions such as data logging, statistical functions, communication interfaces for connection to computer systems or networks and programmable settings for specific application requirements. For use in industrial environments, many weighing indicators have robust designs that can withstand dust, moisture and other environmental influences.

We offer standard amplifiers and indicators but can also help you with a customized design or a complete measurement solution.

There are some important aspects to consider when selecting the right components for digital signal processing, in addition to the standards already mentioned such as OIML, ATEX, IECEx, EAC, NTEP and UL. Here are some other important considerations:

Considering these aspects can ensure that you select the right components for your digital signal processing application, that they meet your requirements and can be seamlessly integrated into your system. Need help with your selection? Get in touch with us!