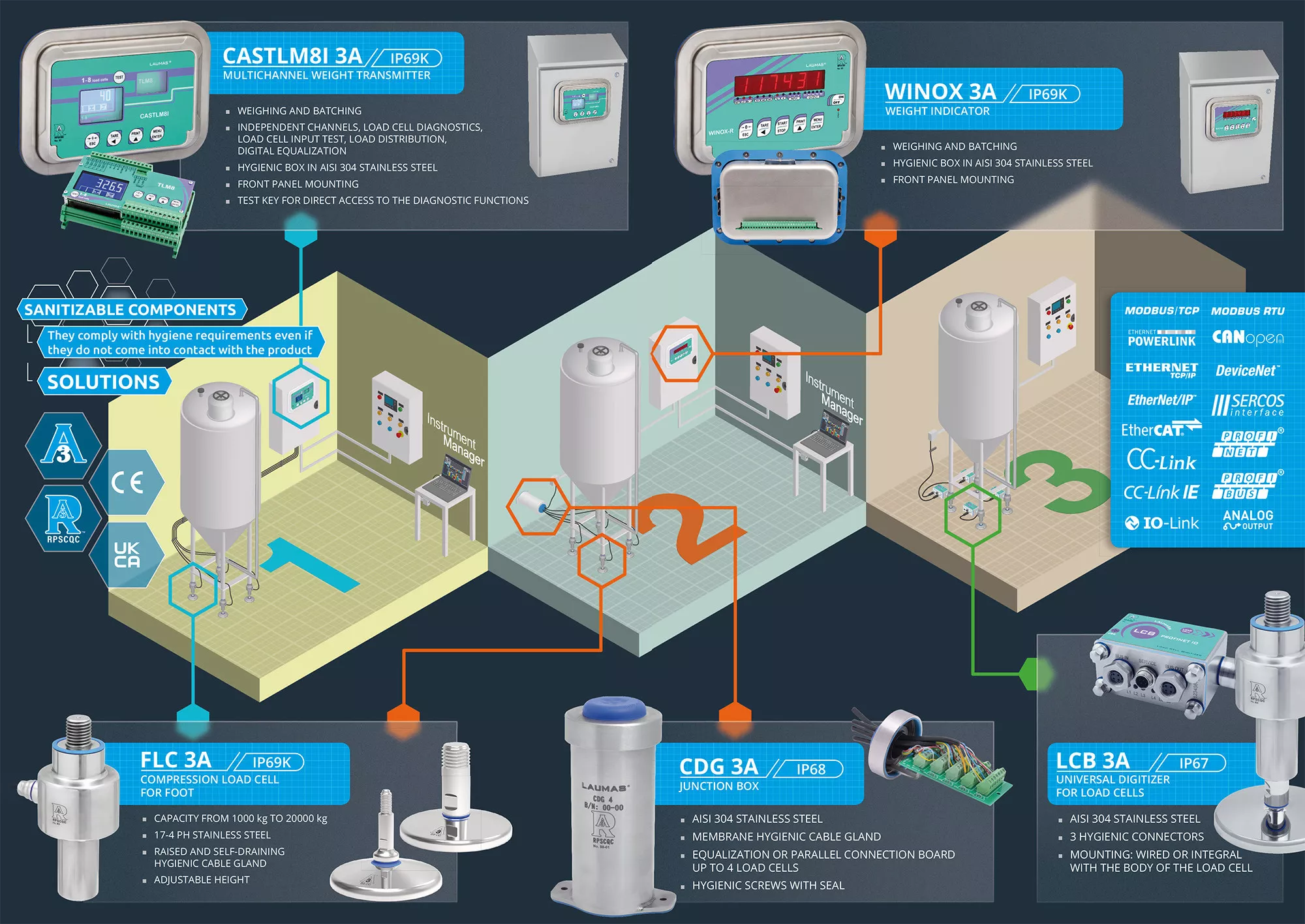

Food industry

Protection against contamination and the ability to disinfect sensors are important features in the food industry. Althen supplies stainless steel forcesensors and load cells and weighing sensors with high IP ratings, which are easy and effective to clean. In addition, we offer an extensive range of mounting kits specifically designed for weighing tanks and silos. We also support the assembly of data recording measurement systems in line with FDA 21 CFR Part 11 regulations.

Sensor solutions for the packaging industry

Our sensors are used in a variety of applications within the packaging industry, such as sorters, fillers, weighing systems and packing lines. The sensor portfolio includes:

laser sensors for accurate positioning and sensing, force sensors for pressure measurement and quality control, weighing sensors and load cells and complete weighing systems linked to indicators for real-time data feed to the PC. These solutions contribute to an efficient, reliable and automated packaging line.

Applications in the food industry

Beverage production

Our products guarantee not only uniform and tight closure of packaging, but also reliable process flow.

Dairy

Hygiene is critical in milk processing. Our products, certified to the 3-A Sanitary Standards, guarantee clean and safe processing in compliance with applicable hygiene standards.

Brewery

Beer today is produced using different processes and systems with different degrees of automation. We provide you with the right measurement technology.

3-A standards: Hygienic plant design

The standards known today as "3-A standards" were established back in the 1920s and used in the dairy industry to improve the hygiene of dairy plants. The name is derived from the three interest groups - the state hygiene officers, plant manufacturers and processors. Today, the membership of the non-profit organization "3-A Sanitary Standards, Inc." consists of three associations: International Dairy Foods Association, Food Processing Suppliers Association, International Association for Food Protection, and representatives from the U.S. Department of Agriculture and the U.S. Food & Drug Administration.

3-A SSI manages a comprehensive catalog of design criteria for equipment and processing systems with the goal of improving food safety through hygienic equipment design. The organization oversees the 3-A Symbol Authorization Program and other voluntary certifications to ensure the integrity of sanitary processing equipment and systems. The 3-A Symbol is a registered mark used to identify equipment that meets 3-A Sanitary Standards for design and manufacturing. Voluntary use of the 3-A symbol on dairy and food equipment provides assurance that the equipment meets sanitary standards.

-

Compliant with hygiene standardsIn the food and packaging industry

-

Long-term PartnershipIn product an process

-

Reliable and ExperiencedProven trackrecord over 75 years

-

Innovative and NewState-of-the-art products and developments

Hygienic weighing technology

3-A certified sensor technology

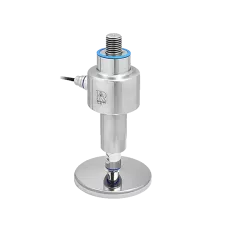

FLC 3A Hygienic compression load cell

- Hygienic device authorized by 3-A SSI

- Cable suitable for contatct with food

- Combined error < +/- 0.1 %

LCB3A Hygienic Universal Load Cells Digitizer

- Hygienic device RPSCQC authorized by 3-A SSI

- Optional fieldbuses

- Micro USB port

WINOX-R 3A Hygienic Weight Indicator

- Hygienic device RPSCQC authorized by 3-A SSI

- 3 logic inputs, 5 relay outputs

Our clients

Applications in packaging

Filling and packaging line

Reliable level measurement and check weighing in your filling and packaging line. Optimize dosing and filling with sensor technology from Althen. Our solutions ensure precise fill level measurement and reliable check weighing, for maximum process reliability and consistent product quality.

Packaging systems

The right sensor solution for every packaging challenge. Whether for food, consumer goods, cosmetics or pharmaceuticals, our sensors offer maximum process reliability and flexibility. Both the product to be packaged and the packaging itself are processed accurately and efficiently.

Productcategories

Single point load cells

- For smaller and medium-sized weighing platforms

- Excellent off-centre load compensation

Bending shear beam load cells

- Measuring range 0 to 27.000 kg

- With moment immunity for high accuracy

- Ideal for weighing applications

Weighing modules & mounting kits for load cells

- Measuring range 5 kg to 100 ton

- Specially designed for loadcells

- Best weighing performance

Measuring amplifiers with bus interfaces (OIML)

- Connect up to 32 instruments

- Amplifiers/indicators for load cells

Indicators with bus interfaces (OIML)

- Indicators for load cells

- Various protection rates available

Digital indicators for weighing systems

- Indicators for weighing systems

- <0.01 % FS Linearity