Linear inductive position sensors in paper making machines

Linear displacement sensing for precise position control

Linear position sensors measure linear displacement relative to a reference position.

They translate movement into an electrical output signal for accurate position monitoring and control.

Different sensing principles are available, making them suitable for both industrial automation and scientific research environments.

Take a look at our range of high-quality linear position sensors for demanding applications.

Discover our range of linear position sensors

We offer standard linear position sensors but can also help you with a customized design or a complete measurement solution.

Linear position sensors are devices that measure the displacement or position of an object in a straight line. These sensors convert mechanical motion into an electrical signal, allowing for precise monitoring and control in a wide array of industrial processes. They find applications in sectors such as automotive, aerospace, manufacturing, and robotics.

We offer linear position measurement technology for a wide range of applications that require accurate travel, distance, or position monitoring. Our portfolio includes both standard and specialised sensor solutions, making it easy to select the right sensor for your application.

Althen linear position sensors are based on different physical measurement principles. This allows us to offer the ideal solution for your installation and performance requirements.

Our sensor range can be divided into:

We also supply intrinsically safe EX position sensors for hazardous areas, including:

These sensors are available in various configurations to match your industry requirements.

Machine equipment often requires sensors that are reliable, durable, and accurate. Our linear and rotary sensors are designed for heavy duty environments and help reduce maintenance costs. They can also support your automation and digitalisation programmes.

Whether you work with small-scale production or high-volume manufacturing, reliable equipment is key to maintaining consistent quality. Our sensors help you measure with confidence, every day.

Choosing between contacting and non-contacting linear position sensors depends on the specific requirements of the application, including factors such as precision, environmental conditions, and the durability needed for long-term use. Contacting sensors are often used in applications where cost is a critical factor, and physical contact is permissible, while non-contacting sensors are preferred for high-precision applications and environments where wear and tear need to be minimized.

They usually involve a direct mechanical connection between the sensor and the moving part. Potentiometric sensors are a common type of contacting linear position sensor. They use a resistive element and a wiper that makes physical contact with the surface. As the object moves, the wiper slides along the resistive element, creating a variable voltage output.

Not ideal for applications where non-contact measurement is essential.

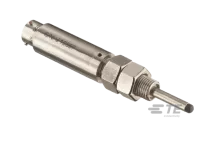

Linear variable differential transformers (LVDT sensors)

Within their specified measurement range, LVDT sensors provide excellent linearity. They are capable of detecting very small changes in position and have virtually unlimited resolution. As a result, LVDT sensors are also suitable for measuring high accelerations and high measurement cycles.

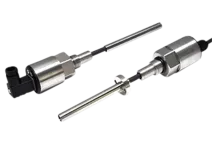

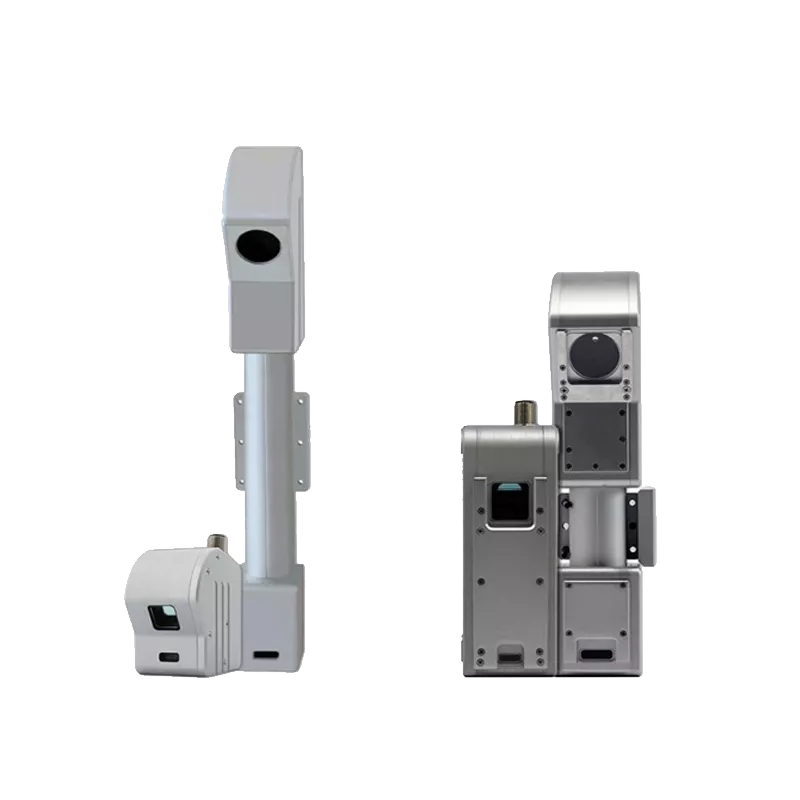

Linear inductive position sensors

Linear inductive position sensors are durable, long-lived, and especially stable under temperature fluctuations. That means they are ideal for measuring linear travel in almost any industrial setting – especially with hydraulic or pneumatic applications.

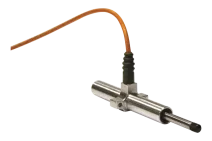

Draw-wire sensors

Draw-wire sensors (also called string pot displacement sensors) can measure distances at up to 0.01 mm accuracy. They measure the position and movement of an object by means of a flexible steel cable that is fed from a spring-loaded spool. The linear movement at the end of the cable is thus transformed into a rotational movement.

Linear potentiometers

Linear-motion potentiometers (potentiometric sensors and displacement sensors) are based on electrical resistance. Their resistance can be altered mechanically (by rotation or transposition). These sensors are primarily used as continuously adjustable voltage dividers. Althen linear potentiometers are highly compact and lightweight, and they come in various configurations.

Hall effect sensors

Sensors based on the Hall effect are used to measure the strength of magnetic fields. Their primary applications are in longevity and stress testing as well as for measuring magnetic fields or the thickness of layers. Our Hall sensors are also available in several modified versions for special requirements.

As technology continues to advance, the demand for accurate and reliable linear position sensors will keep growing. Althen Sensors & Controls supports this development with sensor solutions designed for precision, efficiency, and long-term reliability. From automotive and manufacturing to aerospace applications, linear position sensors play an important role in the ongoing evolution of industrial automation and control systems.

Machine equipment requires heavy-duty sensors. The sensors must be reliable, durable and precise. Our linear and rotary sensors help you save (maintenance) costs and can be part of your automation and digitalisation programme. Regardless of whether it is a small batch or mass production, manufacturing quality products requires quality equipment. Our sensors are designed for high performance applications and offer you long life, exceptional repeatability, high straightness and customised lengths for various applications. Looking for a contactless solution for accurate position measurement?