Smart sensor solutions to challenges in the paper and paperboard industry

Strict regulations and rising material costs are making it increasingly challenging for pulp and paper manufacturers to maintain their margins. To control costs and produce efficiently, it is crucial to prevent breakdowns and avoid unplanned machine downtime. An average paper machine produces up to 1,500 meters of paper per minute, with a width of 9 meters. Thus, any breakdown leads directly to high costs. Sensors play an important role in ensuring process reliability:

- Vibration sensors are used for condition monitoring and preventive maintenance.

- Linear inductive position sensors monitor the roll position in the paper machine.

Due to harsh conditions, high humidity and temperature, sensors in this segment must withstand extreme environments. Therefore, Althen sensors are equipped with:

- A robust stainless steel housing

- IP68 rating for long-term use in humid conditions

- High vibration resistance

Our solutions are designed for reliable performance in the most demanding production environments.

-

A-Class QualityIn product an process

-

Long-term partnershipWith all stakeholders

-

Reliable and ExperiencedProven trackrecord over 75 years

-

Innovative and NewState-of-the-art products and developments

Product categories

Rotary potentiometers

- Measuring range 360° to 3.600°

- Various options in measurement principle

- Motion control & position determination

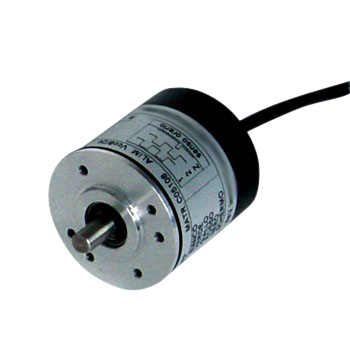

Rotary encoders

- Resolution from 5 bit to 2/36.000 pulse/revolution

- Convert angular position to analogue / digital data

Rotary inductive position sensors

- Measuring range 0° to 160°

- Infinite resolution & long rotational life

- Wide range operating temperatures

4-20 mA vibration sensors

- Measuring range 10 g to 4.000 g

- For application in temperatures over 120°C

- Excellent sensitivity & low noise

General purpose vibration sensors

- Measuring range 5 g to 1.000 g

- Noise from 1.4 mg to 0.1 µg

- Excellent for industrial monitoring

Intrinsically safe inductive rotary sensors

- Measuring range 5º to 160º

- Approved for use in harsh environments

- Excellent linearity down to ≤ ±0.1%

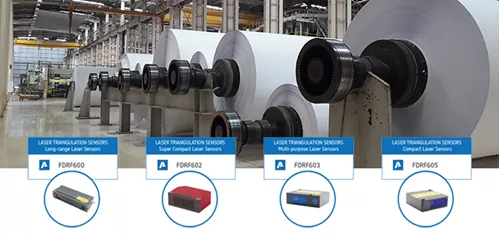

Single point laser distance sensors

- Measuring range 2 mm to 2.500 mm

- High speed & accurate position measuring

- Resolution up to 0,01%

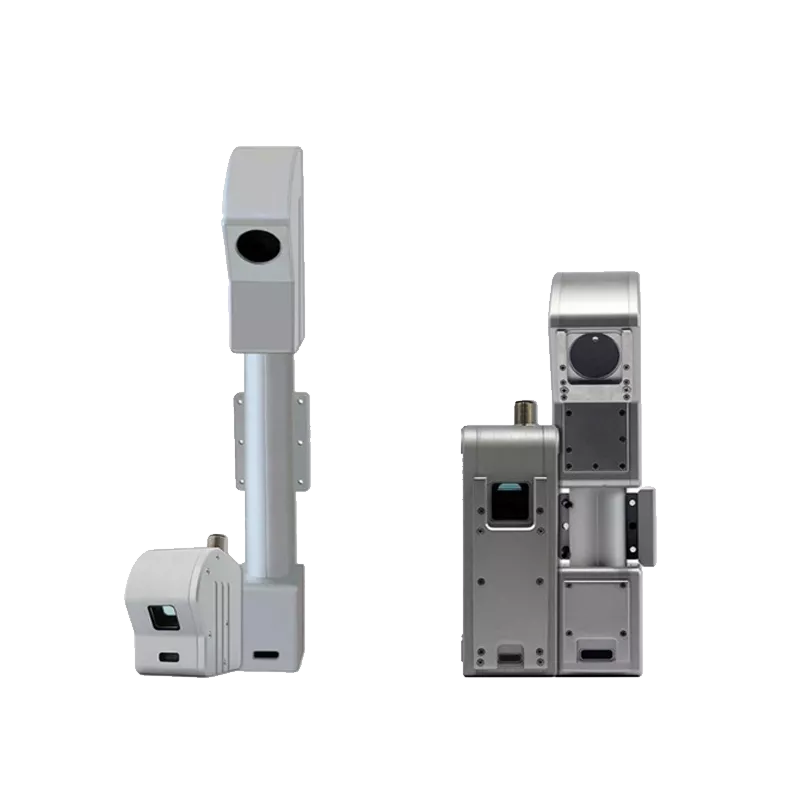

2D laser scanners

- Measuring range 2 mm to 2.500 mm

- High speed & accurate position measuring

- Resolution up to 0,01%

Our clients

Precision at every angle, rotary potentiometers for paper production

Rotary potentiometers are widely used in the pulp and paper industry for measuring and monitoring angular positions of mechanical components. Typical applications are:

- position monitoring of valves and throttling valves

- adjustment of roller and roll positions

- control of dosing systems

- control of air valves in drying lines

- adjustment devices in paper web guides

In these applications, accurate and reliable position control is important, for example when setting a roll opening to ensure constant paper thickness or material throughput.

The sensors provide a continuous analog output signal, which can be directly integrated into machine control for real-time control of processes.

Features

- Analog output (usually voltage or resistance)

- Simple design, cost-effective

- Direct angle measurement without software calibration

Selection criteria

- Required measurement range (e.g., 0-360°)

- Mechanical load capacity (vibration, humidity)

- Lifetime (limited by wear)

Prevent downtime with vibration monitoring

Vibration sensors and acceleration sensors play a key role in the pulp and paper industry by monitoring the condition of rotating machinery. Common applications include motor bearings, drive shafts, rollers, pumps, and fans.

By continuously recording vibration levels, mechanical issues such as imbalance, bearing wear, or loosened components can be detected at an early stage—long before they lead to machine failure.

These sensors are a core component of predictive maintenance strategies. Through detailed vibration analysis, maintenance activities can be precisely scheduled, helping to reduce unplanned downtime and increase operational reliability.

In the highly automated environment of pulp and paper production, this makes a critical difference in maintaining productivity and controlling costs.

Features

- High sensitivity to small vibrations

- Robust design, suitable for demanding environments

- Various versions (piezoelectric, MEMS)

Selection criteria

- Frequency and measurement range

- Temperature range (hot system zones)

- Type of mounting (screw, magnetic or adhesive mounting)

Precision motion control with rotary position sensors

Rotary position sensors, both incremental and absolute, are widely used in the pulp and paper industry to precisely monitor speed, position, and direction of motion. They are typically integrated into drive systems of:

- conveyors

- rollers and drums

- winding stations

- cutting units

The generated pulses enable highly accurate control and synchronization of movements which is crucial for tasks such as exact paper length positioning or precise alignment during printing and cutting processes.

In automated production lines and advanced motion systems, absolute encoders provide an added benefit: they deliver immediate position feedback after a machine restart, without requiring a reference run.

Features

- Incremental encoder: Count pulses, relative position

- Absolute encoder: Each position clearly coded

- High resolution for precise control

Selection criteria

- Resolution (pulses per revolution)

- Interface (TTL, HTL, SSI, CANopen, PROFIBUS)

- Environmental conditions (humidity, dust, temperature)

Reliable angle measurement with inductive rotary position sensors

Inductive rotary position sensors are ideal for applications that require non-contact, wear-free angle measurement—particularly in demanding industrial environments where robustness and long-term reliability are critical. In the pulp and paper industry, these sensors are commonly used on:

- Rotating shafts of mixers or dosing systems

- Wing arms and mechanical linkages

- Control valves exposed to steam, chemicals, or high humidity

Because they operate without mechanical contact, inductive sensors are highly resistant to dirt, oil, moisture, and vibration, making them perfectly suited for harsh operating conditions and dynamic motion. They provide accurate angular position feedback via analog or digital signals, ensuring reliable performance even in high-speed or continuously moving systems.

Features

- Wear-free due to non-contact operation

- Long service life and high durability

- Resistant to oil, dust, and vibrations

Selection criteria

- Measurement range (partial or full rotation)

- Accuracy and linearity

- Electrical interface (analog, digital, fieldbus)

Laser technology for the paper and foil industry

Single point laser distance sensors and 2D laser scanners are particularly suitable for minimizing machine downtime and ensuring consistently high product quality. They measure non-contact, regardless of surface area and with constant precision at all travel speeds.

Accurate and reliable distance measurement with single-point laser sensors

Single-point laser distance sensors are widely used in the pulp and paper industry for high-precision distance and position monitoring. Their non-contact operation makes them ideal for sensitive materials and fast-moving production environments. Typical applications include:

- Measuring the distance between the paper web and rollers

- Monitoring material thickness and layer uniformity

- Positioning of paper stacks and products during transport

- Continuous measurement in dryers or presses for real-time quality control

Features

- Accurate single-point distance measurement (triangulation)

- High measurement accuracy and fast response time

- Compact design, easy integration

- Non-contact measurement, ideal for sensitive materials

- Rugged design, suitable for industrial environments

- Various output signals (analog/digital)

Selection criteria

- Measuring range (distance to target object)

- Accuracy and resolution

- Surface properties of target object (reflective, rough, damp)

- Protection class (e.g. IP65, IP67) and temperature resistance

- Interface to controller (e.g. 4-20 mA, Profibus, Ethernet)

- Mounting options and clear field of view

Advanced surface and contour measurement with 2D laser scanners

In the pulp and paper industry, 2D laser scanners are used for accurate measurements of surfaces and contours. Typical applications include:

- Volume determination of pulp bales

- Measurement of the width of paper webs

- Contour tracking of stacks

- Monitoring paper flow on conveyor belt systems

In addition, 2D laser scanners are used for area monitoring in safety applications, for example around moving machines or robots.

By continuously scanning a surface in a single plane, they generate a large number of measurement points. This enables detailed geometric analysis, for example, to detect deformations, edge shifts or paper path failures.

Features

- Generates two-dimensional laser profiles (surface scan)

- Captures contours, volumes and positions in real time

- High scan resolution and measurement speed

- Rugged housing for harsh industrial environments

- Integrated evaluation possible (depending on model)

- Wide range of interfaces (Ethernet, CAN, RS232)

Selection criteria

- Scan angle (e.g., 180°, 270°) and range

- Resolution and scanning frequency (depending on application speed)

- Environmental conditions (dust, humidity, temperature, vibration)

- Compatibility with existing control technology

- Mounting location and field of view (unobstructed view of scan area)

Projects

Our projects and case studiesChoosing the right sensor: key factors to consider

- Application: Angle measurement, vibration, speed

- Environmental influences: Moisture, dirt, temperature

- Accuracy and resolution: Depending on control requirements

- Interface/integration: Compatibility with existing control system

- Lifetime/maintenance: Low maintenance (inductive) or cost-effective (potentiometric)