Smart sensing for robotics and autonomous transport

Linear and rotary potentiometers, static torque sensors, gyroscopes, and force sensors play a key role in modern automation. They enable precise measurement, control, and feedback, essential for improving efficiency, safety, and system performance across a wide range of applications.

Althen Sensors & Controls supplies high-quality sensors tailored to robotics and Automated Guided Vehicle (AGV) applications. Our solutions are built for reliable operation and accurate data acquisition in demanding industrial environments.

With customised sensor systems, you can enhance your automation projects with greater precision, safety, and process reliability.

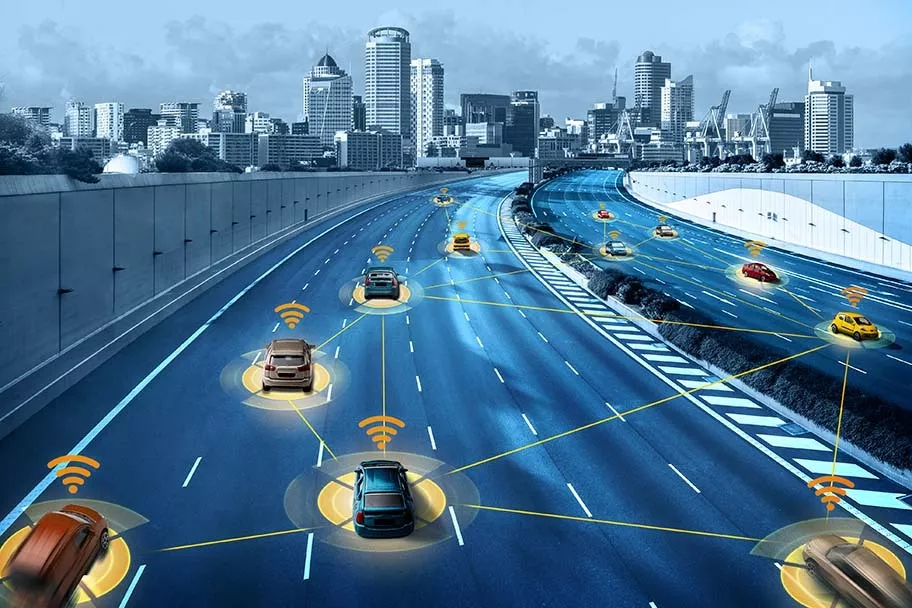

Sensor applications in robotics and AGVs

Positioning and steering angle

Linear potentiometers are used to determine joint positions, particularly in simple or cost-effective robotic systems. They are ideal for collaborative lightweight robots that require accurate positioning without the added cost of high-end encoders.

In Automated Guided Vehicles (AGVs), potentiometers measure the steering angle within mechanical control systems. This data is essential for accurate vehicle navigation and maintaining the correct direction of travel.

Orientation and turning control

In mobile robots and AGVs, gyroscope sensors combined with acceleration sensors (IMUs) are used to determine spatial orientation. This is particularly useful in environments where GPS is unavailable, such as indoor settings. In AGVs, gyroscopes assist with cornering control by detecting deviations while turning or navigating uneven surfaces. This enables automatic corrections, ensuring a stable and accurate driving path.

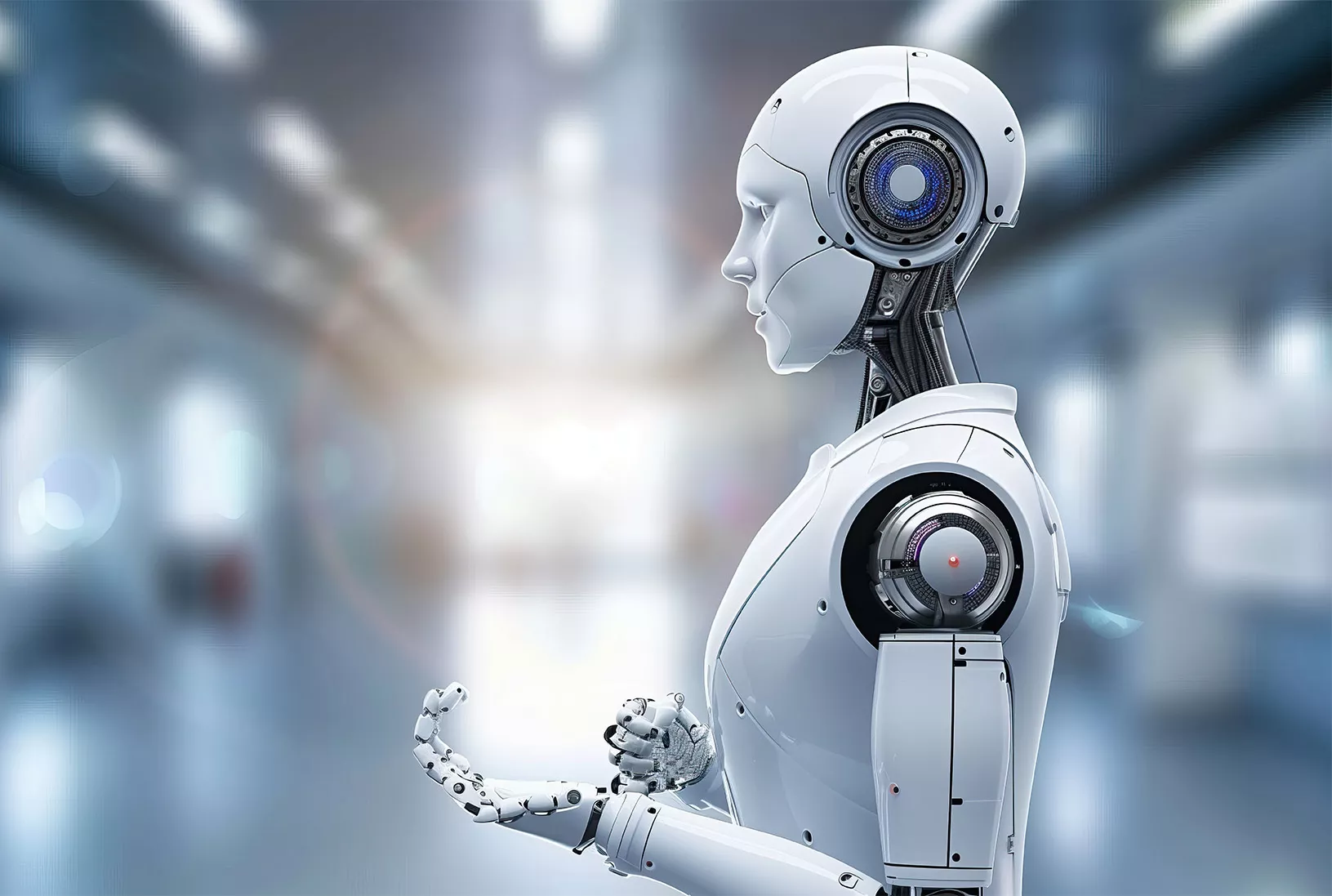

Stability and balance control

Gyroscope sensors are used for the stabilization of humanoid robots. They detect rotational movements and thus support the maintenance of balance, for example, in two-legged robots or robots with dynamic balance according to the Segway principle.

Botsingdetectie en obstakelvermijding

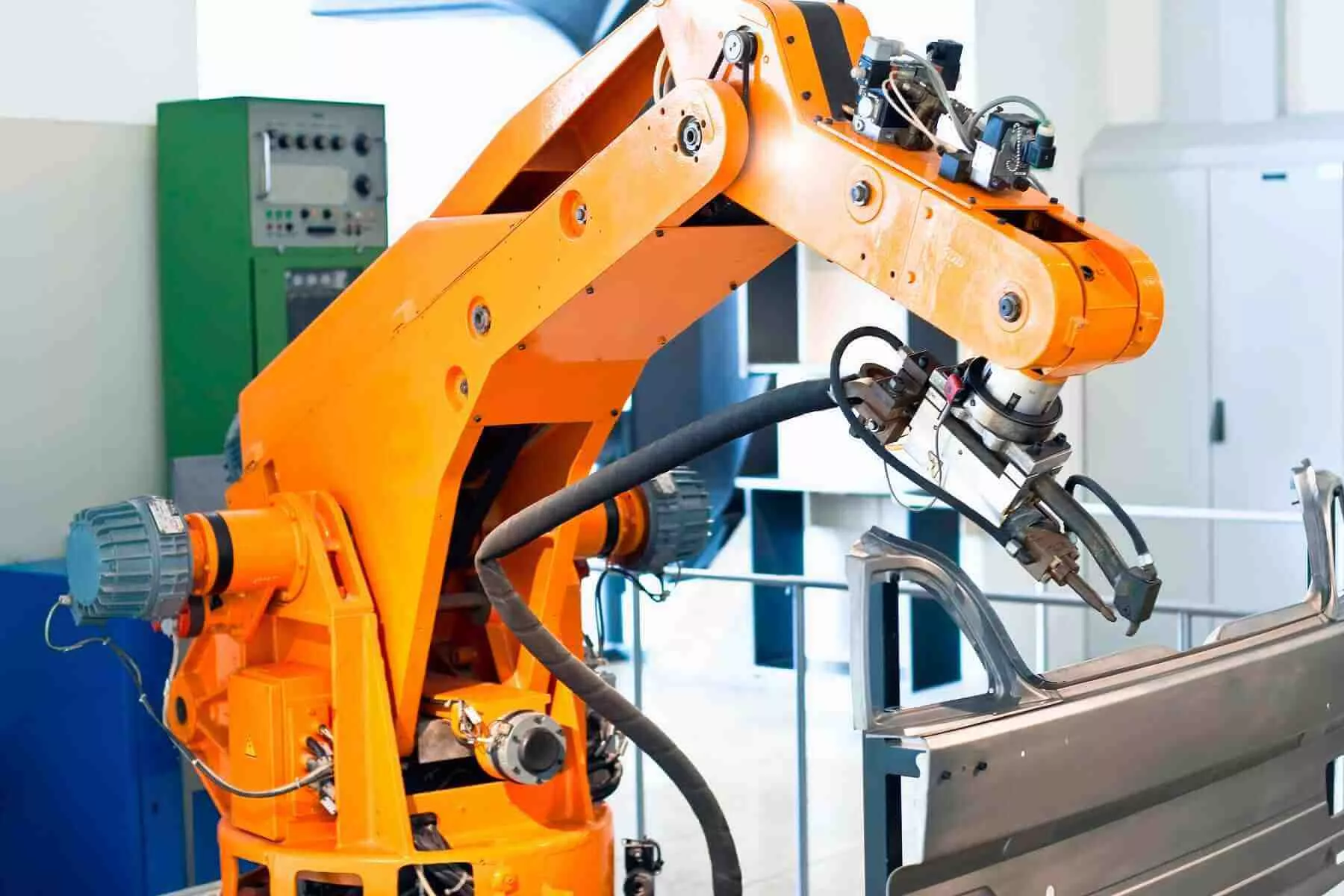

Static torque sensors are used in robots and AGVs for collision avoidance and detection.

In robotic arms, they help detect unexpected forces or obstructions, enhancing safety in human-robot collaboration (HRC). In servo drives, static torque sensors play a key role in the precise control of force and torque, enabling smooth and sensitive joint movements.

Force-regulated gripping and installation

Force sensors control the gripping force in robotic grippers. They monitor and regulate the applied force, allowing robots to safely handle delicate objects such as glass or electronics without causing damage.

In production robots, for tasks like pressing or assembling components with a defined force, force sensors ensure precise and controlled assembly, improving both quality and process reliability.

Overload detection and protection features

In mobile transport robots, force sensors are used for load monitoring and to protect against damage. For example, the sensors measure the load on the loading surface or on connected aids.

-

A-Class QualityLight weight and reliable sensors

-

Custom madeTailored to your needs

-

In-house prototypingRelatively short lead times

-

Call of ordersGuaranteed short lead times for serial production

Products for robots and AGV's

Linear potentiometers

- Measurement range 10 mm to 1.000 mm

- Compact in size and light in weight

- Conductive plastic or wirewound

Rotary potentiometers

- Measuring range 360° to 3.600°

- Various options in measurement principle

- Motion control & position determination

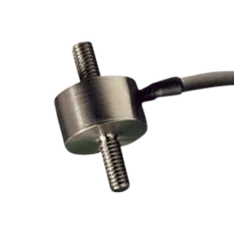

Reaction torque sensors

- Measuring range 0.01 to 50.000 Nm

- Excellent non-linearity

- Perfect for measuring static torque

Standard gyroscopes

- Measuring range 10 to 50 in/sec

- Rugged and corrosion resistant

- Internally integrated to velocity

Our clients

Wide range

In modern robotics and automated guided vehicles (AGVs), sensors play a central role in the reliable control and monitoring of a variety of motion and interaction processes.

Different types of sensors enable precise positioning, orientation detection, force control and torque monitoring. Below is an overview of the most important sensors and their typical applications within robotic systems and AGVs.

Linear potentiometers are often used in robotics and AGVs for position feedback in linear motion systems, e.g., in robotic arms, grippers or in AGVs for monitoring the extension and retraction of components.

Static torque sensors are used in robotics to ensure proper torque in joint movements and manipulators. In AGVs, these sensors help maintain stability and control during acceleration, deceleration or lifting.

Gyroscope sensors are of great importance in robotics and in automated guided vehicles (AGVs) for orientation detection, motion control and navigation. In robotics, gyroscopes help maintain balance, stability and orientation. They allow robots to adjust their movements based on changes in their position.

In AGVs, gyroscopes support precise navigation. They adapt to changes in terrain or direction, ensuring precise movements and obstacle avoidance.

Force sensors are indispensable in both robotics and automated guided vehicles (AGVs) for applications requiring force feedback and control. In robotics, force sensors support sensitive tasks such as object manipulation, assembly and cooperation with humans. They provide controlled and smooth interactions.

In AGVs, force sensors are used for tasks such as load handling or automatic docking. They enable precise force application and ensure safe connections and careful picking up or putting down of objects.

Sensor solutions to fit your needs

Advanced sensors enable robots and AGVs to work autonomously, navigate safely, recognize objects and perform tasks accurately. Althen Sensors & Controls offers a wide range of high-quality sensors tailored to the specific requirements of industrial automation. They guarantee reliability, accuracy and efficiency in automated processes.

In addition to standard solutions, specialized sensors are used in robots and AGVs, such as:

- Image processing and light-based sensors (such as cameras and LiDAR) for object recognition, inspection and visual navigation

- Ultrasonic sensors for collision detection and movement in confined spaces

- Gas, temperature, humidity and chemical sensors for environmental monitoring, control and optimization

These technologies enable flexible, safe and future-oriented automation.

By using Althen's sensors, it was possible for us to build a compliant system that can measure external influences through sensors for the very first time. Now we can respond to external input and imbalance. We are able to provide the first self-balancing exoskeleton in the world. Althen proved to be a highly competent and reliable expert that isn't afraid of that extra mile.

Robotica projects

Our projectsRelated sensors

Popular products for robotic applications

13FLP Series Linear Potentiometer

- Measuring range 12 mm to 100 mm

- Resistance value 500 Ω to 20 kΩ

- Miniature conductive plastic model

10HP Multi-turn Potentiometer

- Measuring range 3, 5 or 10 turns

- Small wirewound potentiometer

- Independent linearity ±0.35% to ±0.1%

46HD Multi-turn Potentiometer

- Measuring range 3, 5, 10, 15, 20 or 30 turns

- Resistance range 10Ω -20kΩ to 50Ω -200kΩ

- 46 mm outer diameter

FSCB22A Sinus Cosinus Potentiometer

- Measuring range: 360°

- Precise 360° sine/cosine output

- Multiple diameters available

ALF255 Miniature Load Cell

- Miniature diaphragm loadcell

- Measurement range: 10kg, 20kg, 40kg, 80kg, 160kg, 320kg, 640kg

- Tension, compression and bi-directional

FCP50A Single-turn Potentiometer

- 51mm outer diameter

- Servomount type with ball bearings

- Various special specifications available

The future of sensors for robotic and AGV's applications

Advancements in sensor technology will focus on enhancing autonomy, precision, adaptability, and safety in these industries. Future sensors are expected to integrate multiple functionalities within compact designs, enabling more sophisticated perception systems. Innovations in AI-driven sensor fusion will allow machines to process vast amounts of data efficiently, enabling quicker decision-making and improved real-time response. Additionally, sensors will likely become more robust, reliable, and cost-effective, fostering wider adoption across industries. Emerging technologies such as quantum sensors, improved LiDAR systems, tactile sensors, and advanced imaging techniques will further propel the evolution of robotics and AGVs, enabling them to navigate complex environments, interact more intuitively with objects, and perform a broader range of tasks with unparalleled precision and efficiency. These advancements promise to reshape the landscape of automation, driving the development of smarter, safer, and more versatile robotic and AGV systems.

Empowering robotic and AGV applications

In the robotics and AGV industry, sensors collectively enable machines to interact intelligently with their environment, offering precise control, accurate navigation, and enhanced safety measures. Discover how Althen Sensors & Controls provides a comprehensive range of these sensors, ensuring robustness, accuracy, and reliability to meet the demands of these rapidly evolving industries, ultimately contributing to increased efficiency and performance in automated systems.

Also joysticks for robots and AGV's

Althen Sensors & Controls offers a comprehensive range of industrial joysticks meticulously designed for the precise control and operation of robotics and Automated Guided Vehicles (AGVs). Our industrial joystick solutions are engineered to meet the stringent demands of these dynamic industries, providing ergonomic design, robust construction, and precise control functionalities. These joysticks are tailored to facilitate intuitive and accurate manipulation of robotic arms, grippers, and various AGV systems, allowing operators to navigate, position, and maneuver equipment with unparalleled accuracy and responsiveness. With a focus on durability and reliability, our industrial joysticks are equipped with advanced sensor technology, ensuring optimal performance and enduring functionality in challenging industrial environments. Whether for intricate robotic tasks or agile AGV operations, Althen Sensors & Controls' industrial joysticks are poised to optimize control, enhance efficiency, and contribute to the seamless automation of diverse applications across industries.